Richard said:

But – I can relatively easily adjust the chuck using light taps on the body with a plastic-headed hammer.

So TonySimmonds comment :

The screws fastening the chuck body to the backplate are too tight, they need to be just snugged up.

is invalid – the chuck is not 'stuck' due to the mentioned 'screws'

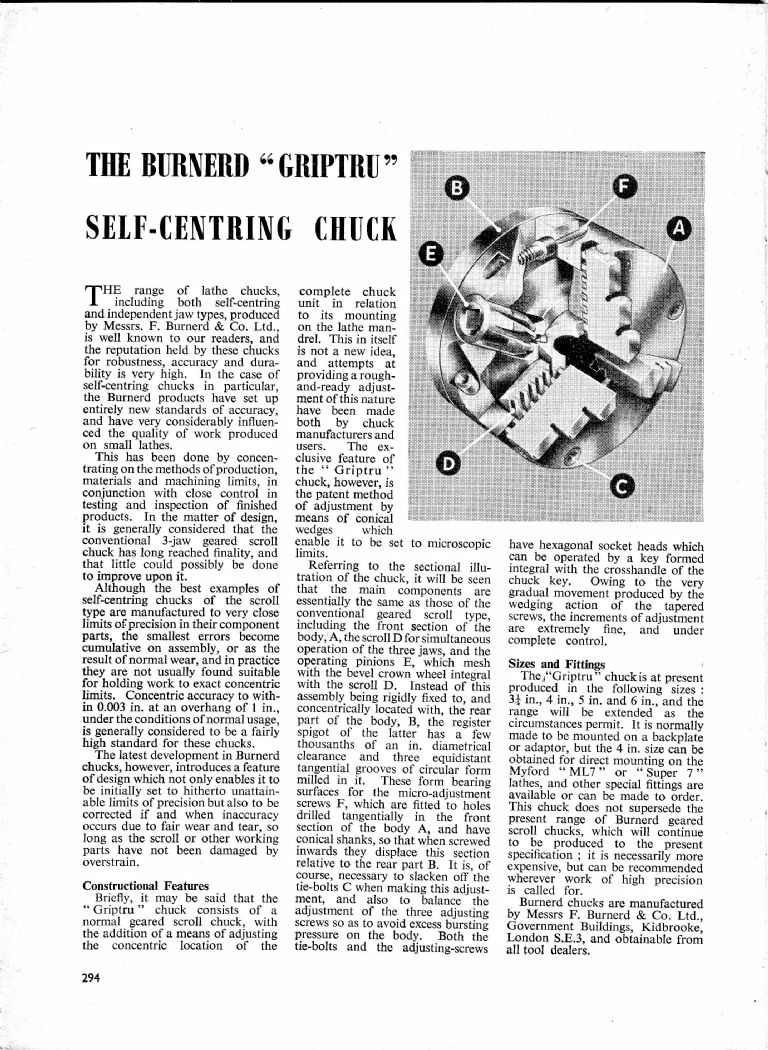

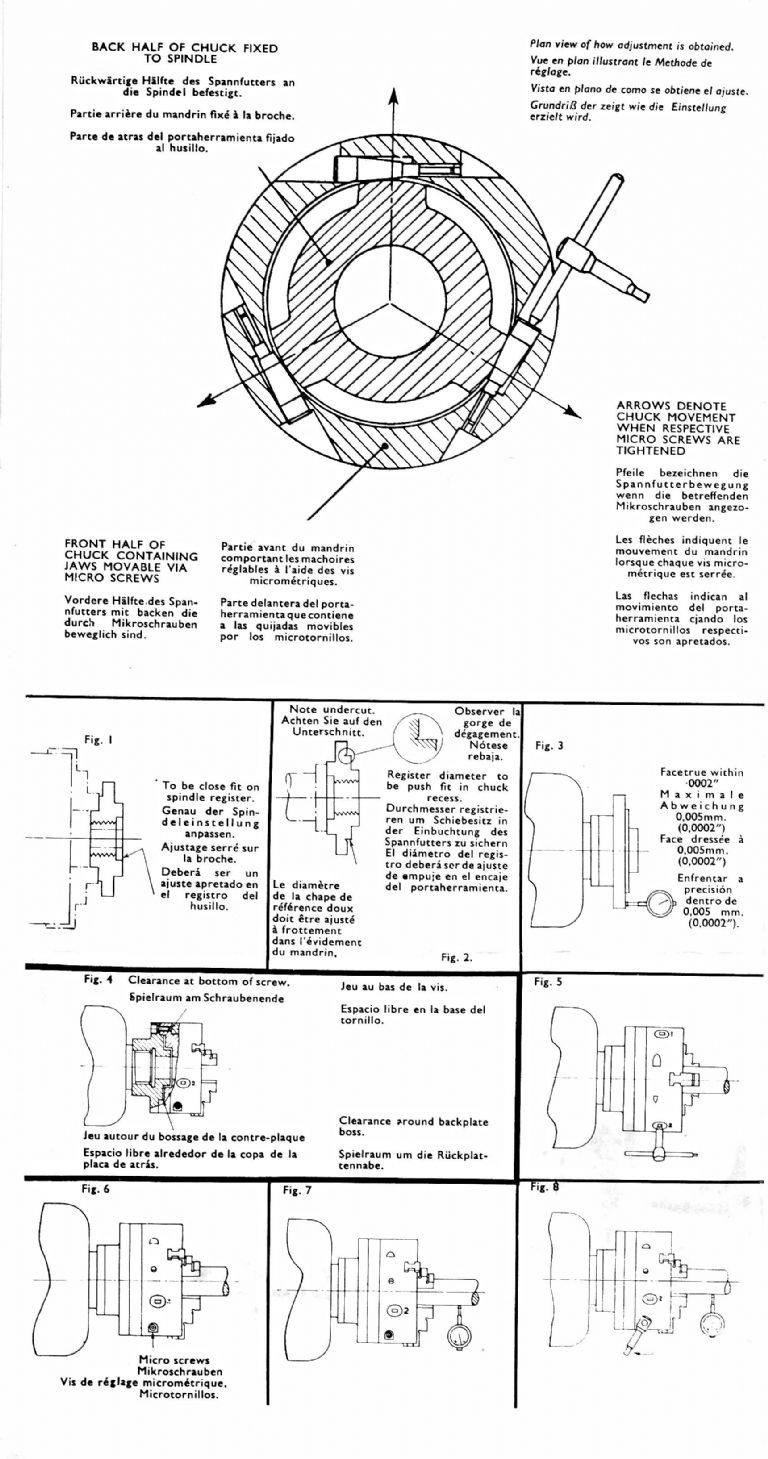

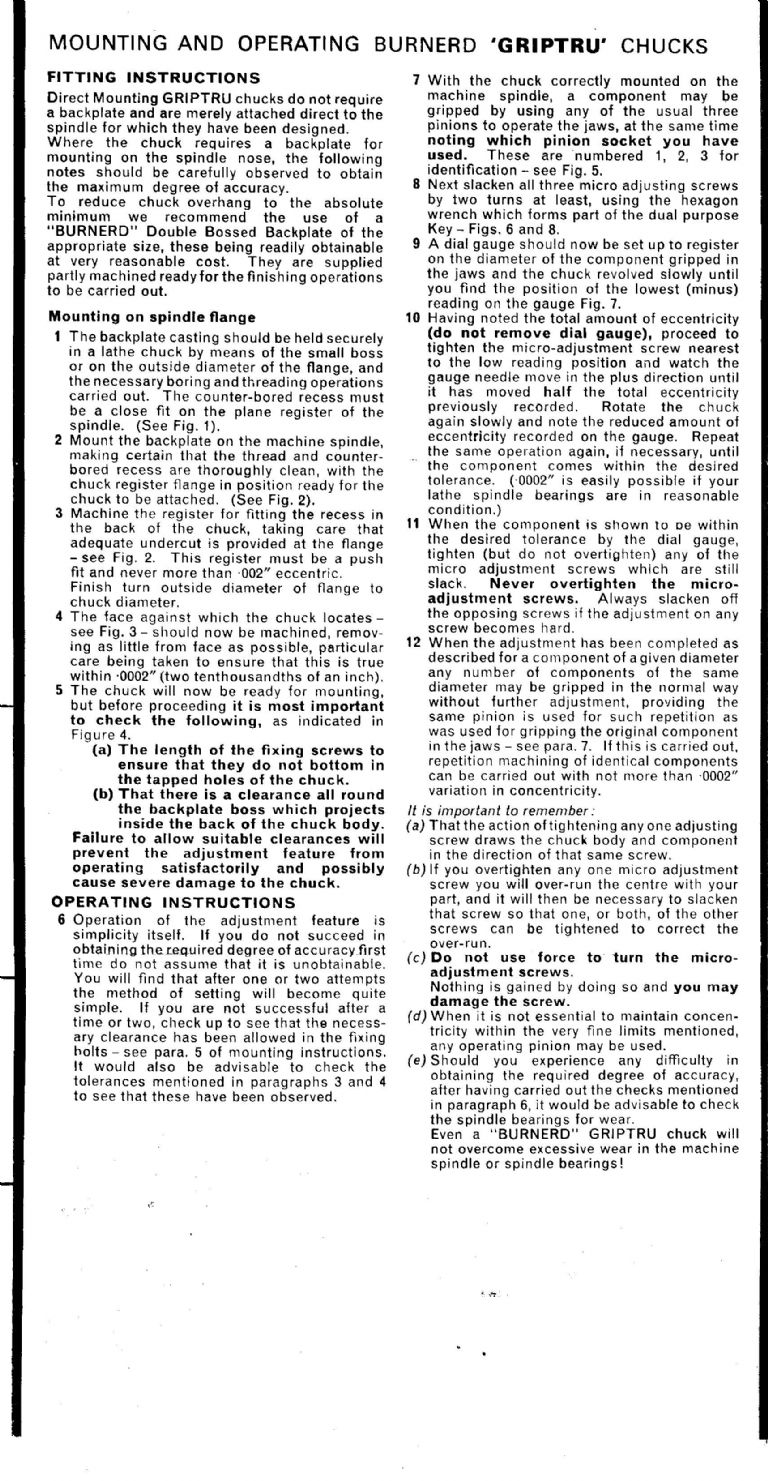

In fact , is is quite clear in the Grip-True and in the ROHM ZS Hi-True ( works in the same way as the Grip-True) documentation that the bolts fastening the chuck body to the spindle backplate are NOT to be loosened whilst adjusting the chuck concentricity.

Per the ROHM Manual:

Adjusting the chuck for concentric gripping

No mounting screws to be loosened for this adjustment

1. Chuck a workpiece or test mandrel and determine the

maximum indicator reading.

2. Depending on the position of the eccentricity, loosen one

or two of the adjusting screw spindles located opposite

the point of the maximum indicator reading.

3. The retighten the remaining one or two screw spindles

until the gripping centre has been corrected by an

amount corresponding to half the indicator reading.

4. Check radial run-out again and repeat the adjusting procedure

if necessary.

5. Lightly retighten the previously loosened

Richard, do the adjustment screws rotate easily? Can you loosen all three up completely, and lightly tap the body over in the direction of one of the adjusters, as far as it will go, then gently screw in that adjuster as far as it will go and observe if the body moves away from the screw?

Joe

John Hall 7.