Hi Roger

I don't think that development of these hobby balance machines

has advanced by any great amount over this time.

These simple machines only provide a location for adjustment

on both sides as opposed to a true geometric position within

an object.As can be seen from some additional photo's in

the album in the case of these compressor wheels material

is removed from the disc at the rear and the protruding hub

at the front and is shown by the red marks.

These compressor wheels would be considered

as a drum rather than a disc for balancing purposes and

should be balanced in two planes .

These locations may not be the true positions where weight

should be removed but are the only safe places that can

be done .

A similar condition would exist in the example of the cup grinding

wheel as there would be little scope in being able to remove

material to achieve a balanced condition.

An article by Keith Johnson in MEW 180 " Balancing grinding

wheels" shows some method of attaching adjustment weights to

a cup grinding wheel and i would think this would be the best way

forward.

In the next photo on the left is a silicon carbide cup wheel for use on the

Quorn grinder ,it was always out of balance from day one as can be seen

a blob of plasticene placed by trial and error long before i had a

balance machine effected a cure.

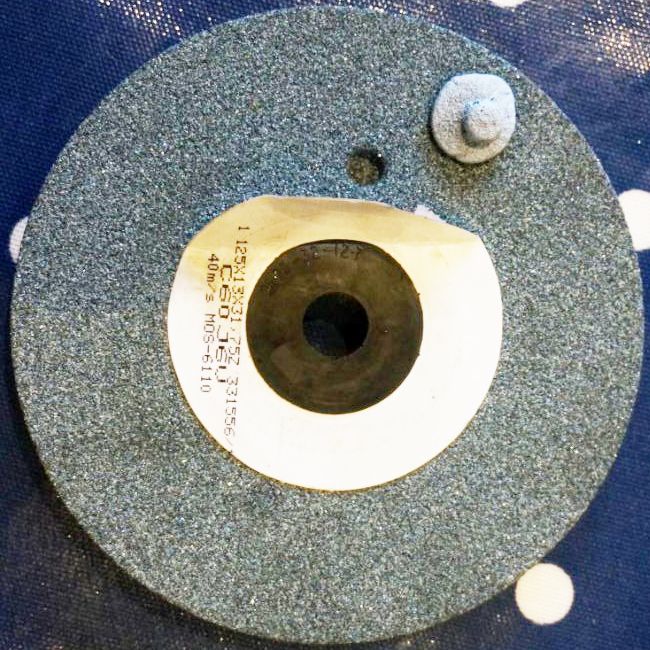

The wheel on the right is a 125mm taper cup wheel and has a

balance adjustment visible here at the rear ,this wheel is for the

Universal grinding machine and as such the hub was made

deliberately heavy and as such shifts the centre of gravity of the

whole assembly.

I have only used the cradle in the next photo to balance this.

The one occasion where the balance machine came to the rescue

was with my bench grinder ,it had a secondary function in that it

could be used to settle concrete the vibration was so bad.

This was an internal rotor imbalance problem ,a couple of extra

steel disks were fitted inside on the rotor and the rotor balanced

on the machine ,the result was no more vibrations and round wheels

after dressing.

These simple hobby type of machines will never be able to compete

with the computational type of machines that seem to be available

in the real world and i would think they would be beyond most

people's pockets.

John

Watford.