Hi,

I was about to posts this and saw the thread on Grinding Tool Bits. The thread seems to cover standard square HSS tool bits, but I need to cut a tool bit from a piece of cylindrical HSS blank.

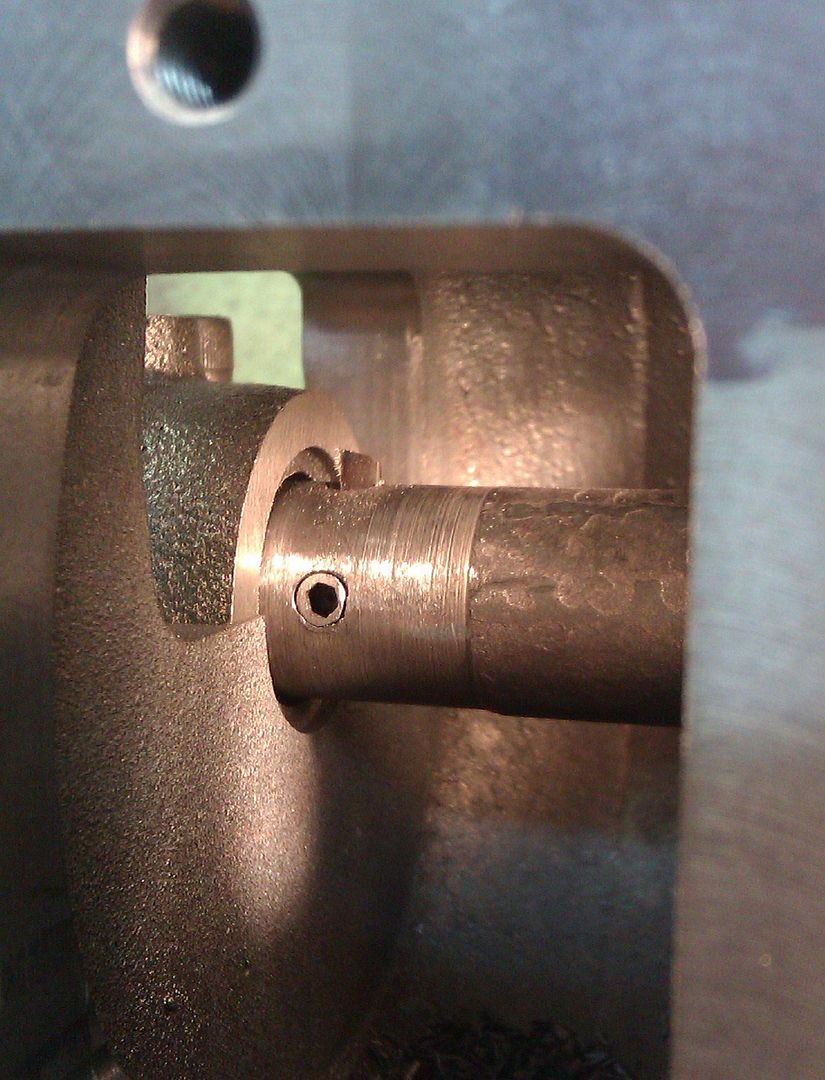

I have a thread showing a custom fly cutter / single point end cutter that I am trying to make. It is basically a fly cutter with a pilot guide in the base. To keep things simple I was advise to use cylindrical HSS so that I only need to drill a hole for the tool bit to fit in and secure it with a grub screw at 90 degrees.

For ease here I have extracted the info from the other thread ref the tool bit here.

Posted by William Harvey 1 on 02/07/2021 10:27:05:Posted by Stueeee on 01/07/2021 21:35:14:

Machine the cutter from a single piece of mild steel. Doesn't need to be anything fancy; I usually use EN3B, EN1A should be OK too. 'A' series valves are 9/32 diameter, so that's going to be the size you're going to machine your pilot to. Once you've machined the pilot, put the job in a pair of vee blocks and drill across the piece immediately above the 9/32" section to the same size as whatever piece of round HSS you're going to use.

Once that's done, turn the piece 90 degrees and drill the hole for the grubscrew. The drilled hole needs to be the tapping size for whatever size grubscrew you choose. It needs to be smaller than the toolbit diameter; e.g. if you are using a 5/16" diameter toolbit, then aim for a 1/4" or 6mm grubscrew. At the top of the piece crossdrill again for the tommy bar.

Re. grinding the toolbit, to produce a flat cut, the cutting edge needs to be at 90 degrees to the pilot. Orientate the tool bit in the hole so that it has zero or negative rake, otherwise the toolbit will 'dig in' while you're cutting.

Extracted Thread Stops here.

So, following that advice I bought the 5/16 HSS and some 6mm Grub Screws

The tool is based on this image, however the tool in the image is for cutting an angled valve seat. The tool I am making is for cutting a reference cut in the valve seat area for lowering the chamber floor (or more accurately, raising the chamber roof). So instead of a radiused cutting tip the cutting tip will be flat.

In the image below, this is what I believe the tool tip will need to look like, to achieve the recessed cut around the valve seat area. The image below shows a clearance of 5 – 8 degrees, however instead of positive rake (as in the image below) my tool bit will need a negative rake.

In the image above I assume we are looking directly at the end of the tool bit.

I see from the Grinding Tool Bit thread, cutting HSS is hard. The piece I have is 100mm and I need to cut it in half – what's the best way to do this?

I bought a White Grinding Wheel to grind the bit, but don't have a tool bit grinding rest?

Can anyone point me to any guides or videos on making and sharpening a square ended round cutting tool from a round piece of HSS?

Many thanks

Nigel Graham 2.