Posted by Mark Rand 15/11/2021 10:33:49

——————

Posted by John P on 14/11/2021 22:27:02:they are only limited by the drive belt

which gives up due to the centrifugal force flexing the belt as seen here ,the belt

has so much tension it needs some effort to fit over the pulleys but turns into

chewing gum at high speed.

——————

For future designs, would it be better to use nylon reinforced flat belts? They are

nowhere near as stretchy as the round polyurethane belt.

——————————————————-

Hi Mark,

Most probably .

Like most things some compromises have to be made,

manufactured belts are fixed sizes and as such what they fit on has

to be designed to make them fit ,that would have caused me somewhat of a

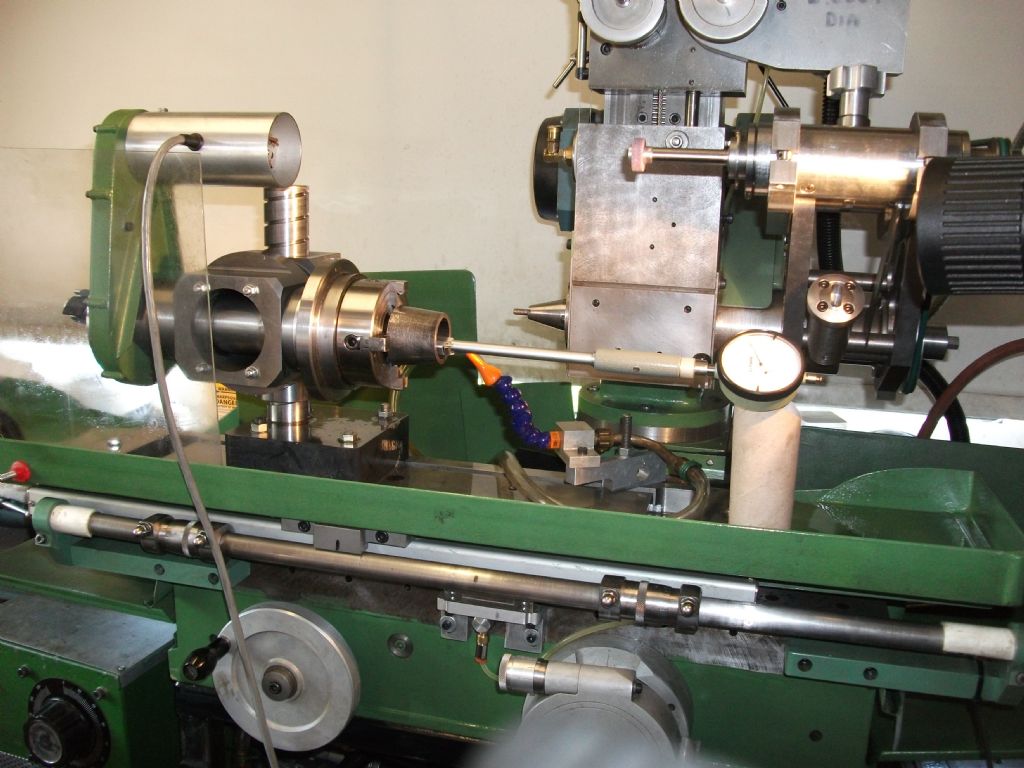

problem as to accommodate the swing up head seen here no adjustment

is possible to tension the belt.

As the spindle has a working speed from about 4,000 to the

31,000 rpm accomplished via belt changes and inverter

regulation additional problems with other fixed belt sizes would undoubtedly

be present, the heat joint belting gets around these complications just by

being able to be made to suit, the inconvenience of the belt flexing

only occurs above the 31,000 rpm which is more than enough for

the internal grinding for which it is designed.

Looking on the lathes web site at some of the past type grinding machines

this machine does rather well in spindle speed terms some examples:-

Crystal lake grinder internal spindle speed 17,500 rpm

Jones and Shipman Universal Grinding spindle 11,600 to 16,200 rpm

Jung internal grinding machine 30,000 rpm

Mipsa Swiss 23,000 rpm

Duplex toolpost spindle 18,000 rpm

Jones and Shipman 36"x 12" 3080 to 33,000 rpm

These are just a few ,i am sure there will be some more ,i guess there is

an upper limit on driving a spindle by belts,it would seem that i am already

up at the top end compared with some of these well made names.

I have an air spindle that runs at around 50,000 rpm for those times

when that this may be needed.Since the machine was originally designed

as a cylindrical grinder and is also a surface grinder along with the

internal facility some inevitable compromises have been made ,it just

what you have to do to build something like this.

John

John P.