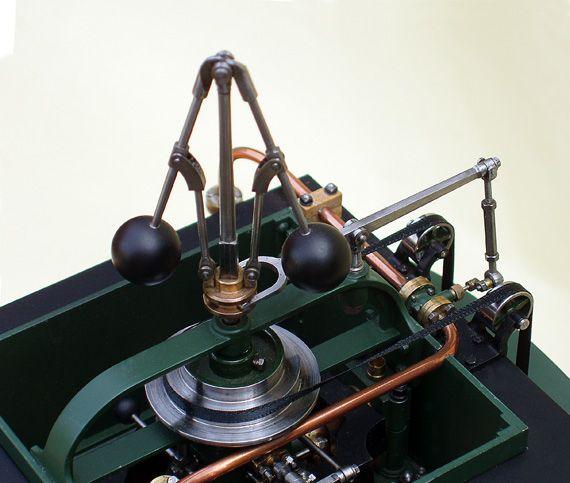

Thanks for the kind feedback gentlemen. First the drive belt. This is still a problem really. The main snag is that it has to pass through the governor fame, before joining (no rubber bands then! ) When it was originally exhibited, the belt was made from two pieces of gummed brown paper parcell tape face to face, with the end staggered to make a lap joint. It was surprisingly strong, and worked well, but had to be removed, as something in the paper was attacking the steel pulleys. Next, I mannaged to make a belt from thin leather, with a scarfed joint made with contact "Evostick", applied and joined staight way, and clamped. Again, worked well but more corrosion. Jason B might try either of these for his engine if the the belt can be removed when not on display. The belt in the photo is a piece of black ribbon from a haberdashery shop. It looks the part for display only, but I can't find a glue for it that is flexible enough to go round the pulleys.

Neil asks the size. If you mean the pins, they are about 3/32" at the thick end, its really a matter of what looks right, since the other end is obviously smaller, it has to be a compromise. The engine is one inch to the foot. I can tell you the leading dimensions if you wish. Let me Know.

Yes Merlin it is just the taper that holds it, plus a film of lacquer. I would point out though, that the engine runs at about forty RPM, rarely, and is always checked over first. I am not advocating this joint for anything that has to do serious or lenghty work. I wanted a method that worked and was visually satisfactory at the same time.

As a point of interest, I have an old drawing of Watt governor with the joint drawn in section. Its a rivet! Solid centre section; two domed ends! How on earth could they close the rivet and not pinch the moving part?

Ian S C.