All, I'm building a Princess Royal mill engine:

**LINK**

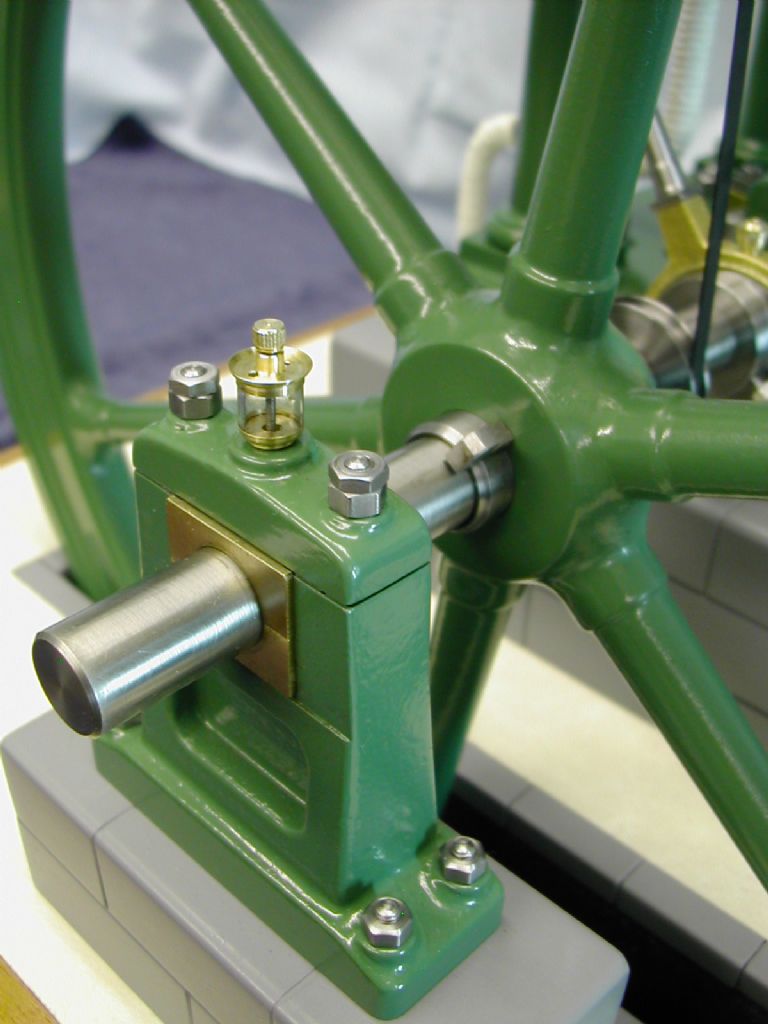

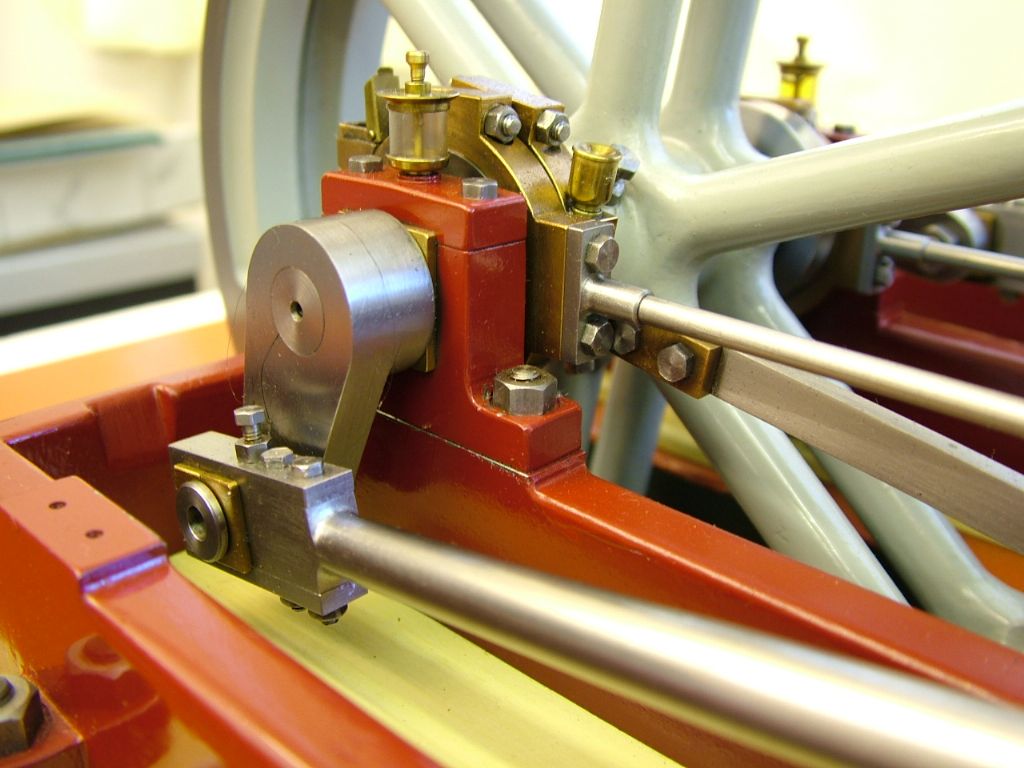

And as a change from machining the larger parts, I am looking at designing a set of oilers for it. The Stuart Turner oilers I used on the 10V are neat, but I guess not realistic since they're open at the top:

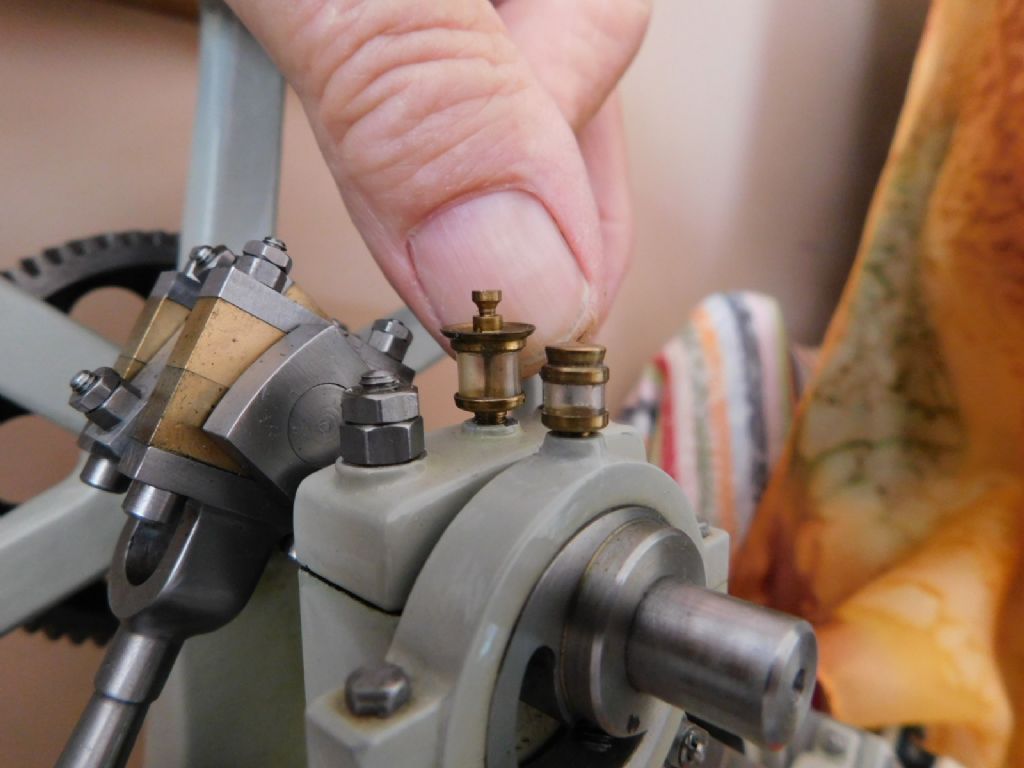

So I'm looking at the 'glass' type oilers. In previous posts, Ramon suggested using cut-down acrylic model rod storage tubes, so I found some, and drew one up on CAD:

Before making a set of them, I'm wondering if I'm on the right lines with the design? I've spigoted the ends of the acrylic so that it fits snugly into the brass cups at the top and bottom. I've made a test piece, and although it fits together nicely, presumably it needs Aralditing together, which seems a bit "non-model engineering practice":

Obviously, it needs its lid, and a hole in the base, which itself would be profiled correctly, and a threaded boss added. Intention is to use a small BA screw in the lid for filling, and also, if I turned the threads off and tapered the end, it could actually work in terms of being adjustable. Alternatively I could drill out the screw and use a needle in the centre.

I would design a set of them at different sizes for other parts of the engine such as the crosshead and crank pin, but perhaps accept that on the eccentric, an open type would have to do due to space constraints.

Am I over-thinking this?

Should it just be a cap with a screw rather than a needle valve?

Are oilers at this small scale usually "dummies" and you just fill them with oil?

Is assembling with Araldite acceptable, or should the acrylic be threaded somehow (would be tricky!).

Any suggestions welcome as always (as would be sources of commercially available items of this size.

Thanks.

Andy_G.

Andy_G.