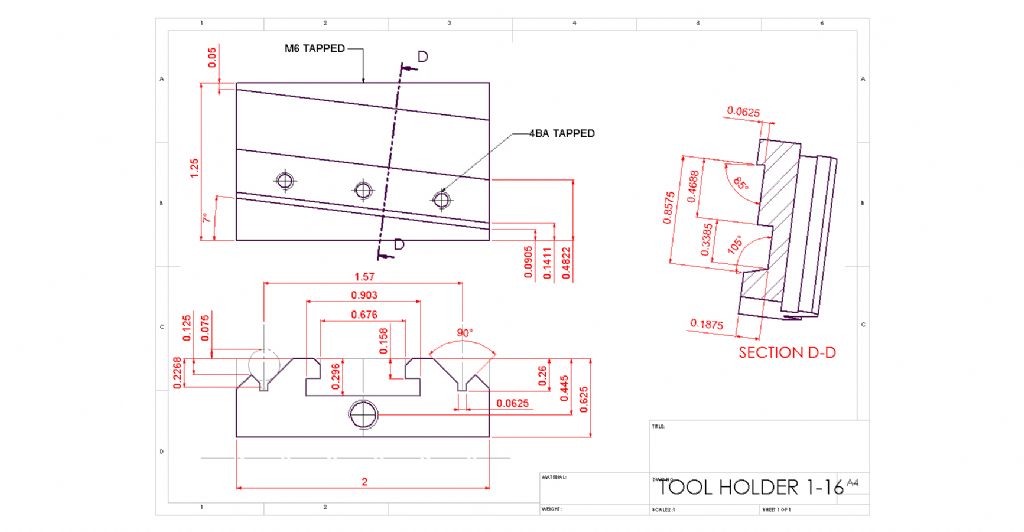

Evening folks, I'm in the middle of a Hemingway GHT Rear Toolpost kit for the S7. I'm very much on a (re)learning curve WRG to lathe work, so please be gentle & use lots of lubrication.

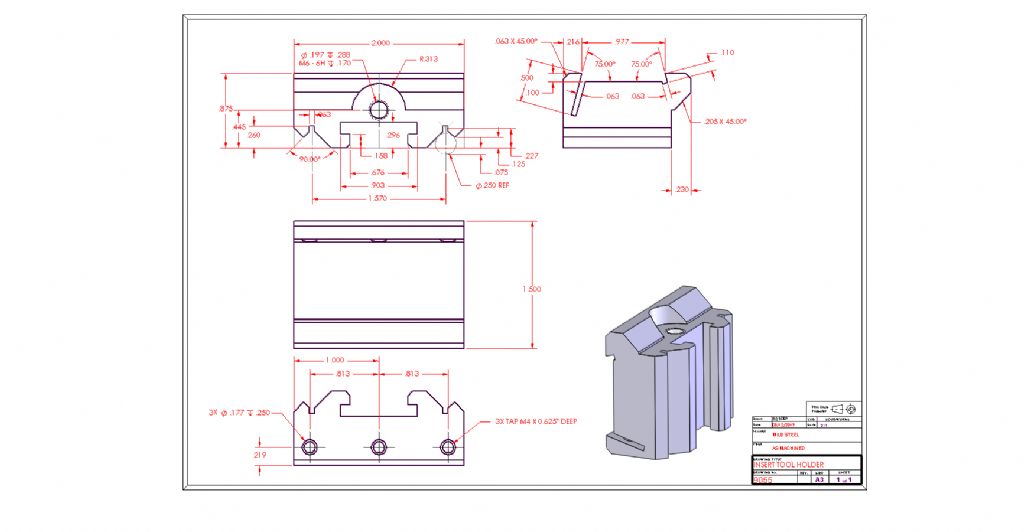

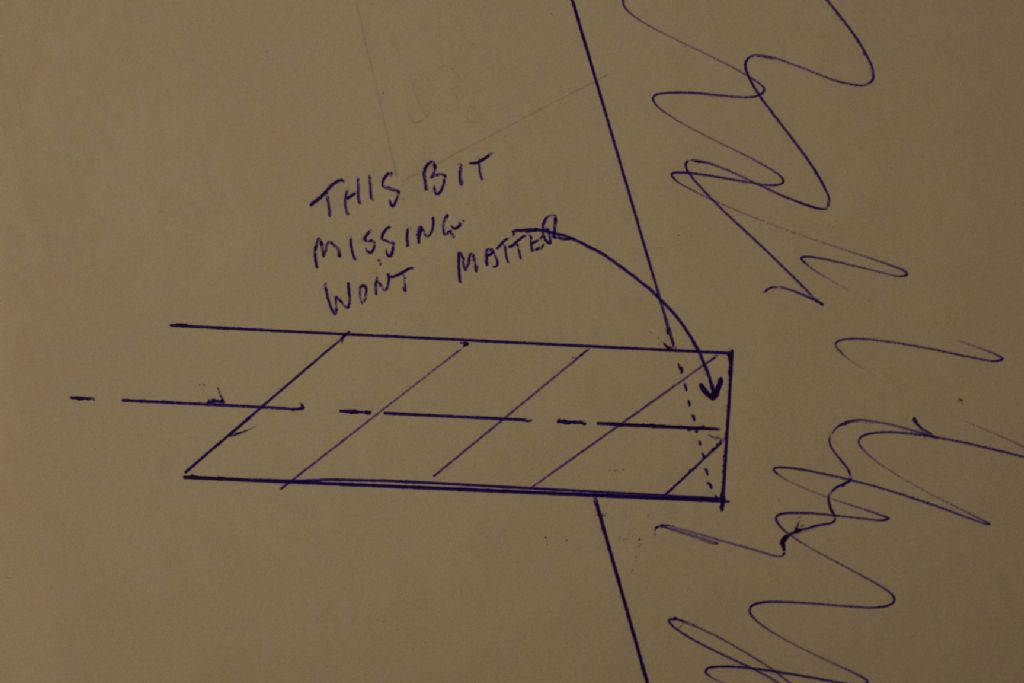

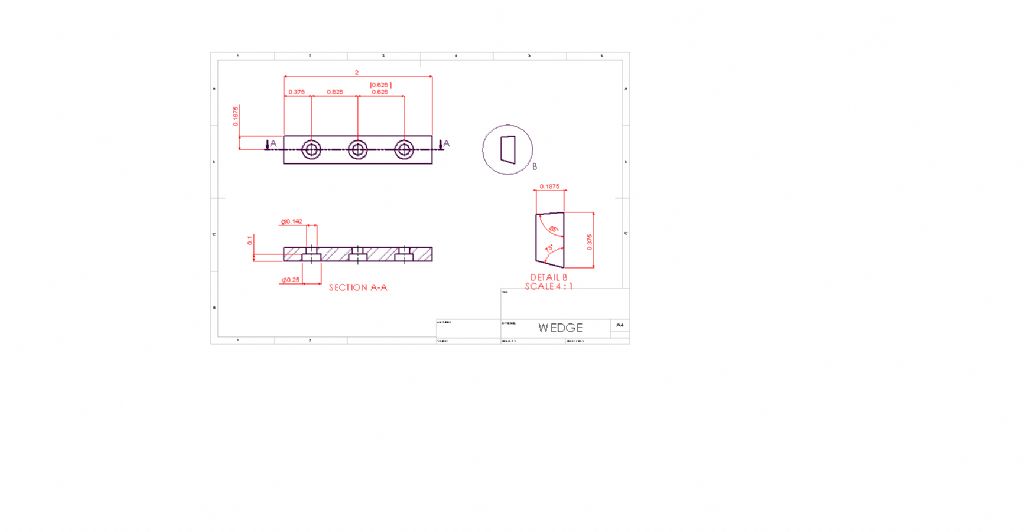

The turret requires a slot milling in it to carry the parting blade, straight forward enough…however, the slot needs undercutting by 8deg on the top & bottom edges to create a dovetail for the parting blade to seat into. GHT blithely mentions in passing that he simply makes up a cutter out of silver steel to perform the undercut…hmmm. The supplied Hemingway drawings show the cutter in its completed state with no info how to make it. I'm assuming that this is something a more experienced bloke would take in his stride, but it's beyond my current skillset. I've searched the forum & the internet for either guidance or an off the shelf readymade 1/4" 8deg dovetail cutter, all to no avail.

Any help would be appreciated.

Oh, and a happy new year.

Howard Lewis.