Hi again, couple of comments which might duplicate stuff you have already tried.

No we're not talking at cross purposes – and moreover you've worked out how to draw on a photo which is more than I have!

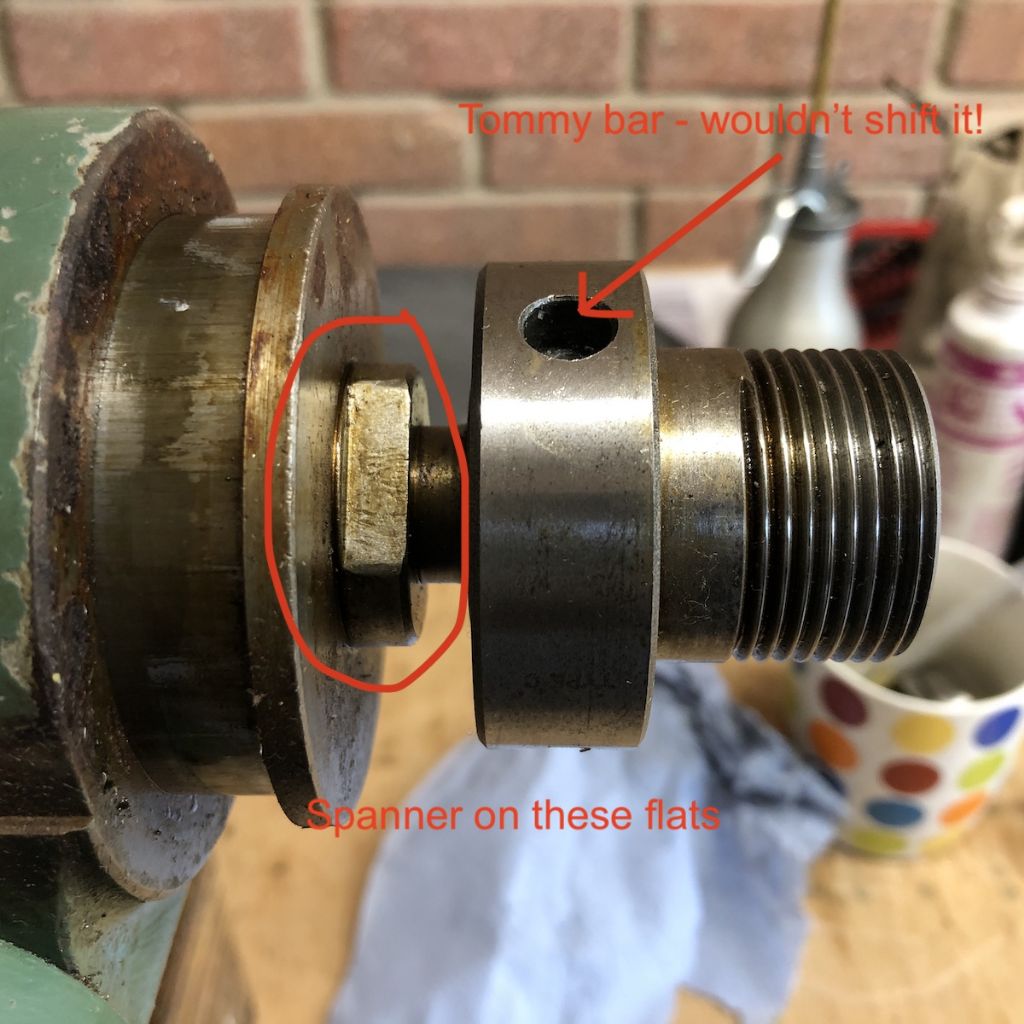

Firstly the ring with the tommy bar holes is jammed down tight as far onto the body of the chuck as it will go – compare my picture with the ring removed. At risk of a silly comment you have taken on board that this is a left hand thread? You should at the very least be able to turn the ring on the body – I bet someone has tightened this and bottomed out the thread thinking it is right hand. It isn't.

The ring should move up freely to contact the end of the quill/spindle – it is presently as far away from the spindle as it is possible to get it. If it was me I'd try a bit of heat on the ring to see if I could loosen it and get it to move. Don't overdo it – if you spit on it and it sizzles it's about right. Make sure you turn it the correct way not the right way!

Now you've got the wedges stuck it's irrelevant. But they'll come out if you knock them back with a suitable punch. A bit of 3 or 4 mm by 40 flat bar would do the job. Remember that a sharp crack with a light hammer (say 8 oz) will do more good and less damage than a heavy blow.

The wedges idea is the same principle, and I like the idea of squeezing them rather than hitting them. Having said that my inner waters tell me that a sharp crack with a hammer on one side with a large heavy lump of steel up against the other side to absorb the blow might well give a higher force than the vice can do. The clamping force of a vice isn't all that high. I've played this game with those wedges getting Jacobs tapers loose – its amazing how much force that taper needs to break its hold. It isn't just about force, it's also about jarring the assembly to shock it loose.

Have you tried giving the draw bar a smack (or two) with the wedges engaged?

Next plan is to try a bit of chemical warfare. Prop the head assembly on the bench so it is in the normal attitude, chuck down. Now find a plastic carton (ice cream tub sort of thing) and prop it under the chuck so the chuck can be immersed in cold water. We're not going to use cold water, we're going to go for a freezing mixture made of crushed ice (normal water ice) and a volatile solvent. Acetone is good, but I bet it would work with the contents of an aerosol of carburettor choke cleaner. Be careful, this mixture will give you frostbite so wear gloves.

Add enough crushed ice to cover the chuck, and add enough solvent to immerse the chuck in the cold liquid. Leave it to consider its sins for 15 mins of so, now try the extraction procedure with wedges and a few sharp whacks on the (loose) draw bar again.

If that don't hack it we're into surgery.

Good luck, let us know how it goes.

Rgds Simon

Howard Lewis.