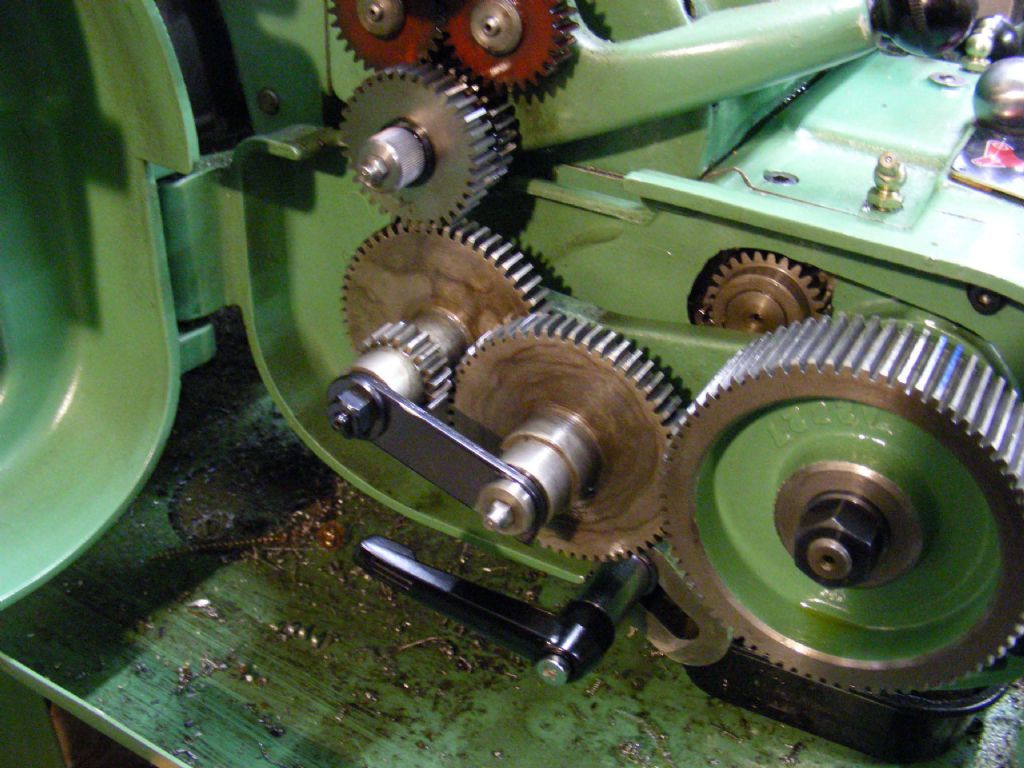

Re-reading Brian Wood's book prompted me to make two small modifications to the Super 7B quadrant designed to make changing the mandrel gear wheel for metric screwcutting a tool-free operation.

As standard, the gear is retained by a hex head screw cum oil nipple which needs the (gentle) use of a spanner and in order to lower the quadrant out of engagement a 3/8" BSF nut has also to be loosened. I have substituted a knurled nut for the screw which is wide enough to give adequate grip and to contain a standard 2BA oil nipple. For the nut, I have adapted an adjustable handle which allows enough rotation to slacken and tighten the quadrant (further projection would have allowed complete turns of the nut/handle but this would then have fouled the cover when closed).

In his book Brian describes a replacement for the somewhat inaccessible clamp screw behind the wide input gear to the gearbox. I haven't yet tried this as I find that, carefully adjusted with a shortened hex wrench, the clamp screw can be set so as not to need turning when the quadrant is moved to install an alternative mandrel gear.

In the photo the 34T is in place and thus far I haven't needed larger gears or the drop arm also shown in the book. I am, however, still looking for the elusive 21T gear!

ega.