Posted by Geoff Theasby on 05/04/2011 15:23:17:

Now then, this raises a question which has been bothering me for a while.

Why do clockmakers use a depthing tool?

Most model engineering is so precise, the more accurate the better, and yet it seems that clockmakers have to hand-fit every spindle and shaft by reference to how well the gears fit together.

Can’t you make the holes in the right place, make the wheels and pinions to the drawings, and have it all fit together nicely as intended?

Regards

Geoff

Geoff –

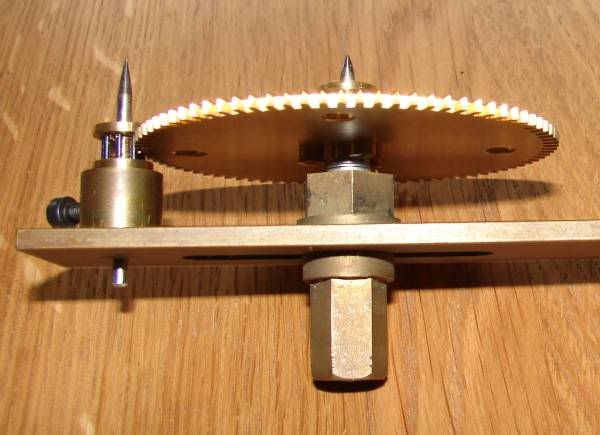

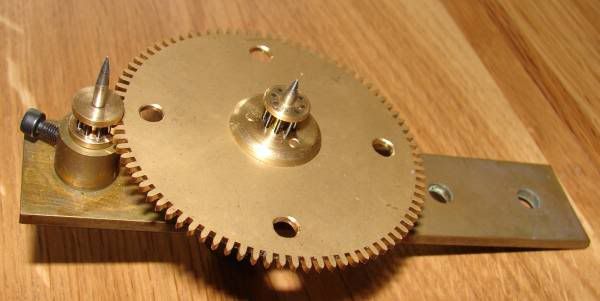

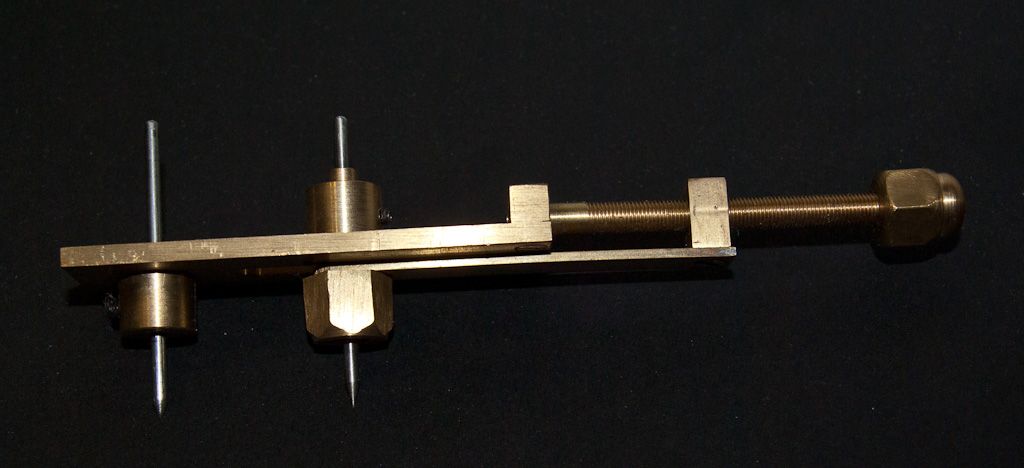

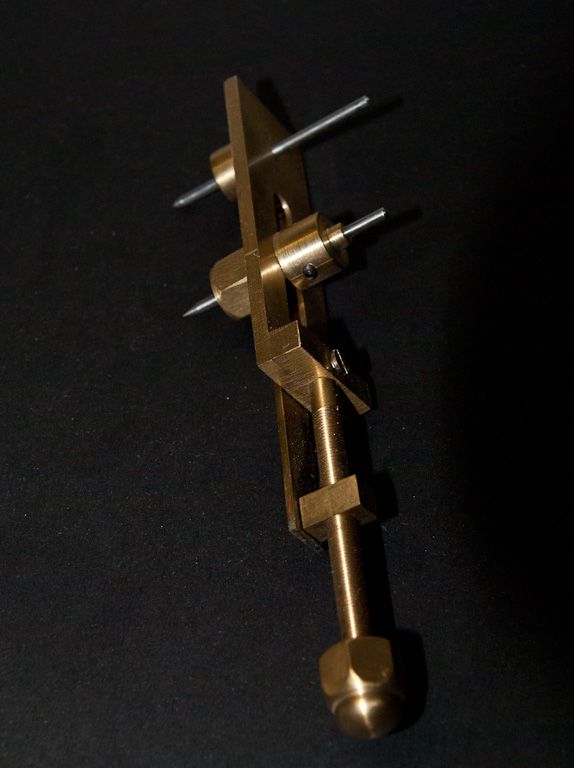

In clockmaking, the objective is to get a good “running fit” between each wheel/pinion pair. In an ideal world, yes you could predict the appropriate centre-to-centre distance to achieve that for a given pair; however, in a world where you are making your own wheels and pinions and the PCD of the resultant object may not necessarily be precisely what it should, you need to use a depthing tool in order to figure out precisely what C-T-C distance you need for the components that you have in hand.

There’s a saying in clockmaking – “if it rattles, it will run” – what you are aiming for isn’t the perfect backlash-free fit, because in all probablility, the resultant friction will be way too high and the clock won’t run. So a clockmaker will err on the side of a loose fit, which will help reduce the gearing friction. Bear in mind that the drive train of a clock involves a massive gearing up; the cord that suspends the driving weight in my long-case clock is wrapped around a barrel 16 times to give 8 days of running, so 1 turn of the barrel represents 12 hours of running, so the escape wheel (which carries the seconds hand) rotates 720 times for each rotation of the barrel. Introduce any unnecessary friction into that system and the clock won’t run.

And of course, given that the drive train is always being driven in one direction, any backlash in the train that may result from your “rattling” fit is of no concern whatever.

Regards,

Tony

roy entwistle.