I know this is quite an old thread but I've been after a 12/25 slow feed cluster for my old ML7 for quite some time and too mean to pay the £40 Myford charge for a factory made one or for a gear cutter for that matter.

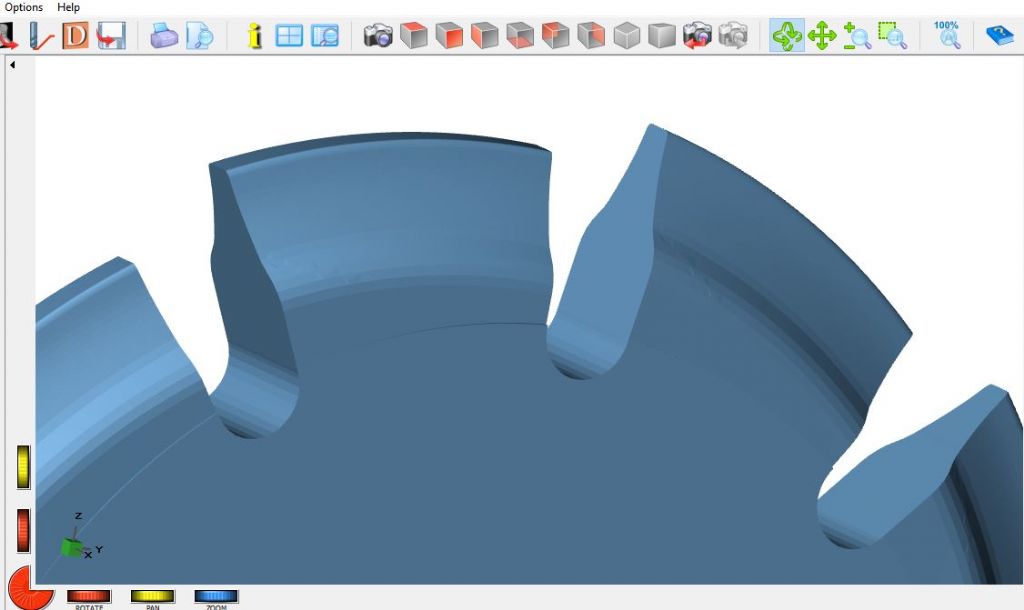

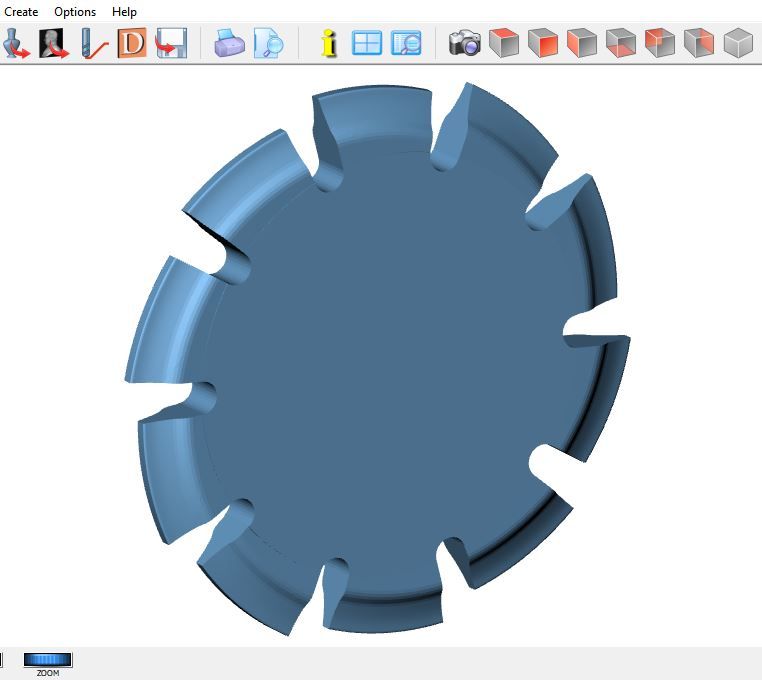

So, I thought I'd give this method a go for making a 20DP 12 tooth gear out of cast iron on a 5/16" keyed shaft so I can use the 25 tooth gear from the change wheel set. I was pretty hesitant having read Jason's comment but thought the only way to find out for sure was to try it.

The spreadsheet from Andy's YouTube channel has an imperial sheet and a quick hack of the page allowed me to add .050" to the diameters to reduce the undercutting and provide more clearance on the 3/8" shaft. I used a small .032" thick slitting saw which is slightly thicker than the value recommended which would be about 0.63mm. I didn't notice much flexing in the saw since the cuts were pretty light after the first two which excavate the majority of the waste.

Anyway, it seems to have worked well. I now have a gear which meshes well with the larger gear it drives in the chain and I now have a working slow feed.

As mentioned above, it's not the fastest method but it does work even for relatively small gears. It's also obviously very low cost.

Edited By Jon Gibbs on 08/06/2022 18:07:39

Jon Gibbs.