Posted by Simon Williams 3 on 29/11/2022 18:44:54:

…

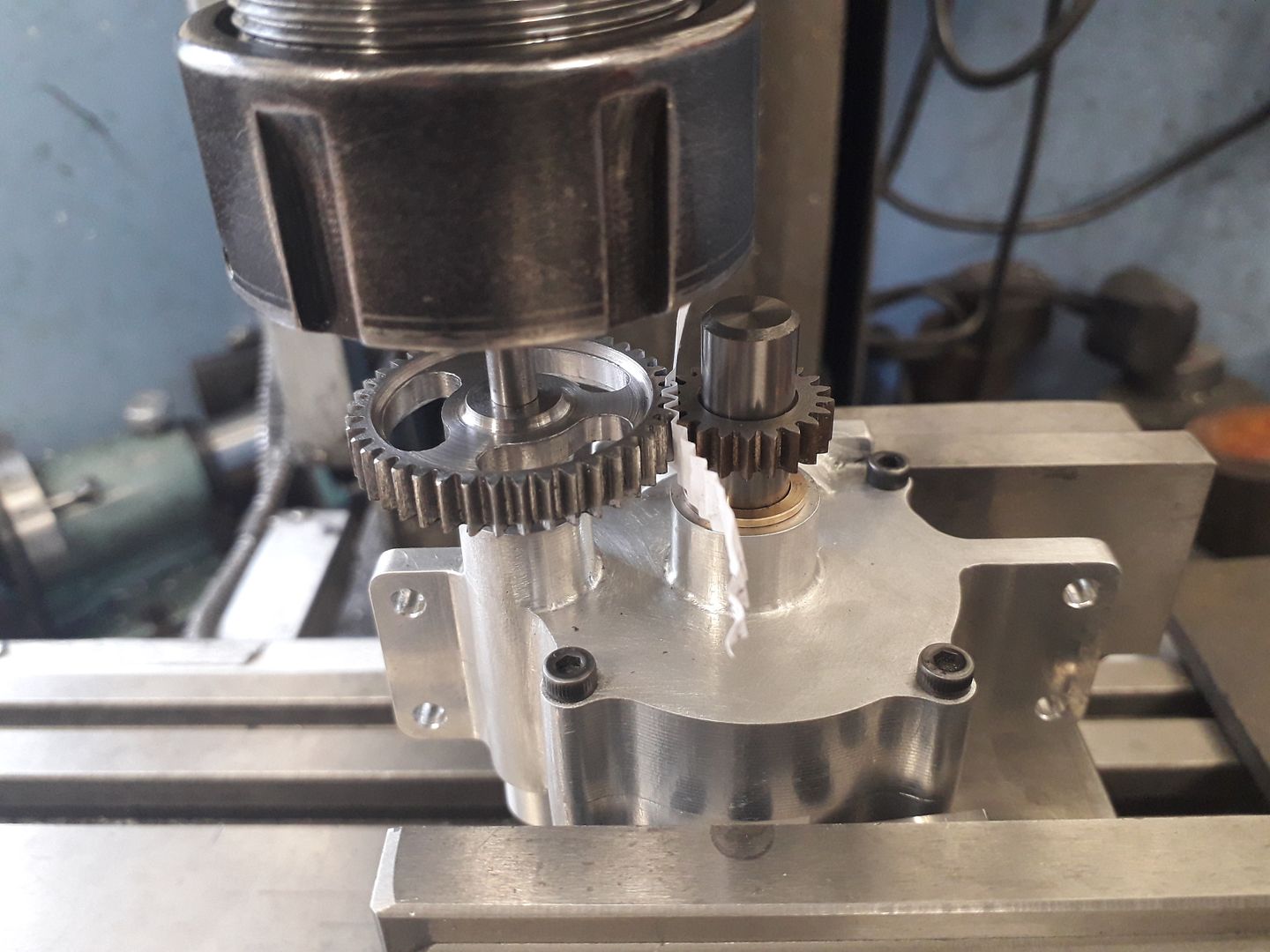

Question for the group – is it asking for trouble to run a gear cut for 20PA against one for 14-1/2 in this application? I note the OP doesn't say which PA the pair gear is, but it becomes 20 deg as the discussion progresses.

…

It is asking for trouble, but whether it matters or not depends on how efficient and reliable the gear chain needs to be. For many purposes, gears can be crudely made – 'good enough' provided they mesh reasonably and don't wear badly in short order. Models tend to be run infrequently and be lightly loaded, in which case the builder can get away with any reasonable mesh.

The same approach is completely unacceptable if gears are expected to transmit significant power efficiently and reliably for any length of time. A mismatched gear installed in tens of thousands of car gear boxes would soon cause obvious trouble. The mismatched gear teeth would wear rapidly, showering metal filings into the bearings, get hot, and clunk, slap and whine.

So a judgment call: mismatching is always a bodge, but it may not matter.

Might possible to tabulate the relative good, bad, and ugly fits between different gear DP and Modules, but my gut feel is it's too complicated. For example, correctly matched involute gears have the useful property of working even if their centres aren't located spot on. I think the degree of interference between incorrectly matched gears varies with the distance between centres, so the same pair might jamb or run depending on the centre distance, which could be tweaked by a bodger to make them work.

Bodging is the Art of adapting stuff to work within a range of circumstances in a way that's reasonably acceptable. Only the bodger can decide if it's 'good enough'. Manufacturing tends to avoid bodging like the plague; apart from one-offs and prototypes it's cheaper to match stuff correctly in the first place.

Dave

Brian Wood.