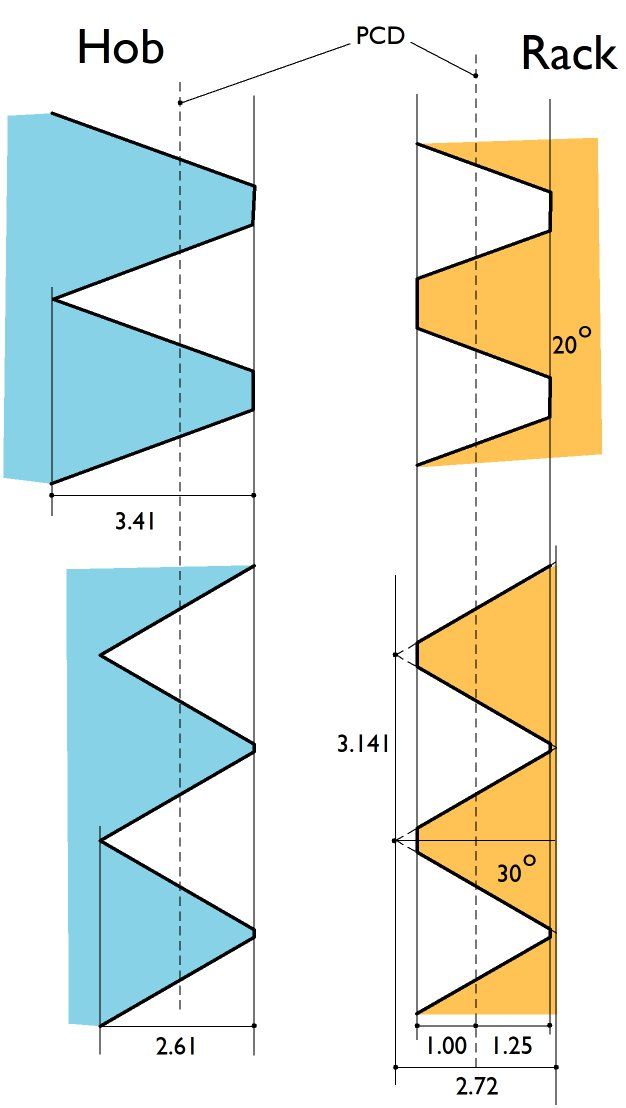

My reference book, Gear Engineering by H.E.Merritt, gives the same formula for the minimum number of teeth without undercutting and with zero addendum modification as DC31k has quoted. It works out as a theoretical 22.1 teeth for 17.5 degree pressure angle.

You can go lower if you apply addendum modification, this increases the diameter of the blank that the teeth are cut on, but there is a limit to how much you can apply before the teeth become pointed and you start to lose the top part of the profile.

With regard to the method used by Helicron, you may start to see more facets as the number of teeth reduces. I seem to remember that the Sunderland gear planer rotates the gear blank and moves it sideways relative to the cutter for a number of strokes before resetting for the next tooth, reducing the number of facets. Someone may correct me on this, it has been a while since I watched a Sunderland in action.This would be much the same action as a Maag or Niles gear grinder if I'm correct.

Perhaps someone else has made some gears in this manner and can share their experience.

Neil

Anonymous.