Just to throw another option into the works if you do go down the 0.8MOD route or even if you stick with the original DP. Many of these full size open crank engines mounted the cam gear on an eccentric stud which allows for any one of many small errors that could creep in during manufacture of not only the gear but the frames also to be adjusted out by simply rotating the eccentric until a suitable running fit is found. Several of the hit & miss engines that I have made replicate this feature.

The other option that I mentioned earlier is depthing the gears where the two are placed in mesh with a strip of something thin between them to give slight backlash and the hole position taken from the actual ctrs of the gears. In this case I would keep the 0.290 dimension and allow any difference to be taken up in the 1.090" vertical direction as you can allow for any change simply you turning the adjustable tappet screw on the opposite end of the rocket shaft.

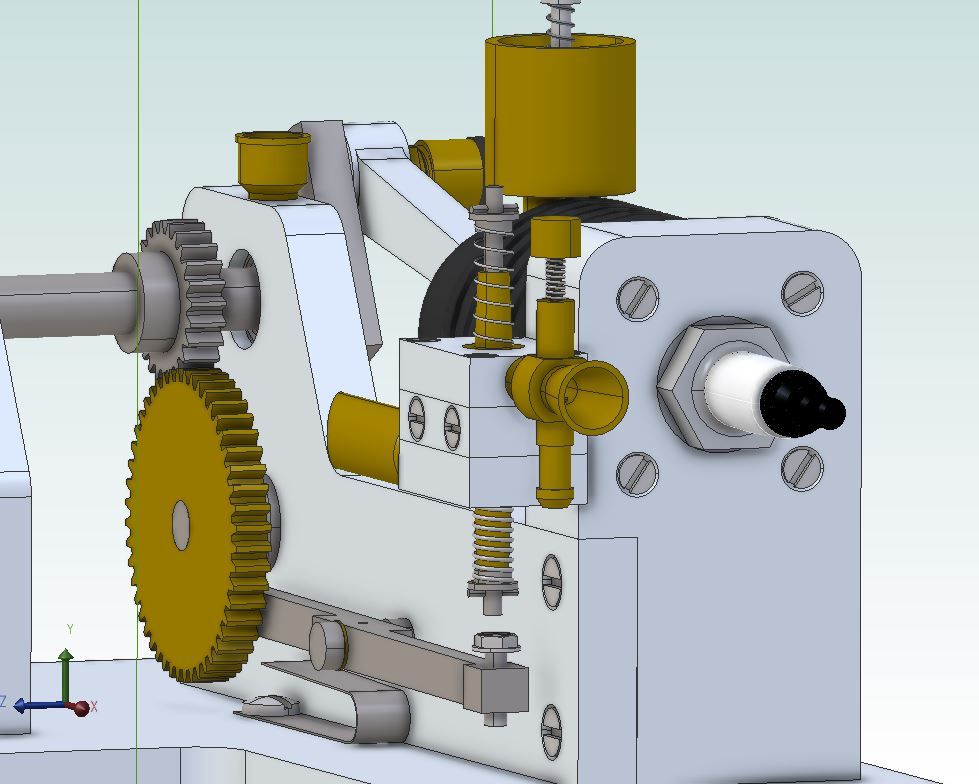

Here is one being done. Locate ctr of crankshaft bearing hole and zero DRO or handwheels. Pop in a temporary shaft and slip the smaller gear onto that. Out a bit of 1/4" dia material into your mill collet and the larger gear onto that. Move 0.290 in x and then adjust Y until the gears turn with the strip of paper between. Note the dro/handwheel reading and or lock the ways then remove gear, spot drill, drill reaming size and ream 1/4"

If you don't have a mill substitute a pointed bit of hardened 1/4" silver steel as a transfer punch for the larger gear to fit onto.

raysal.