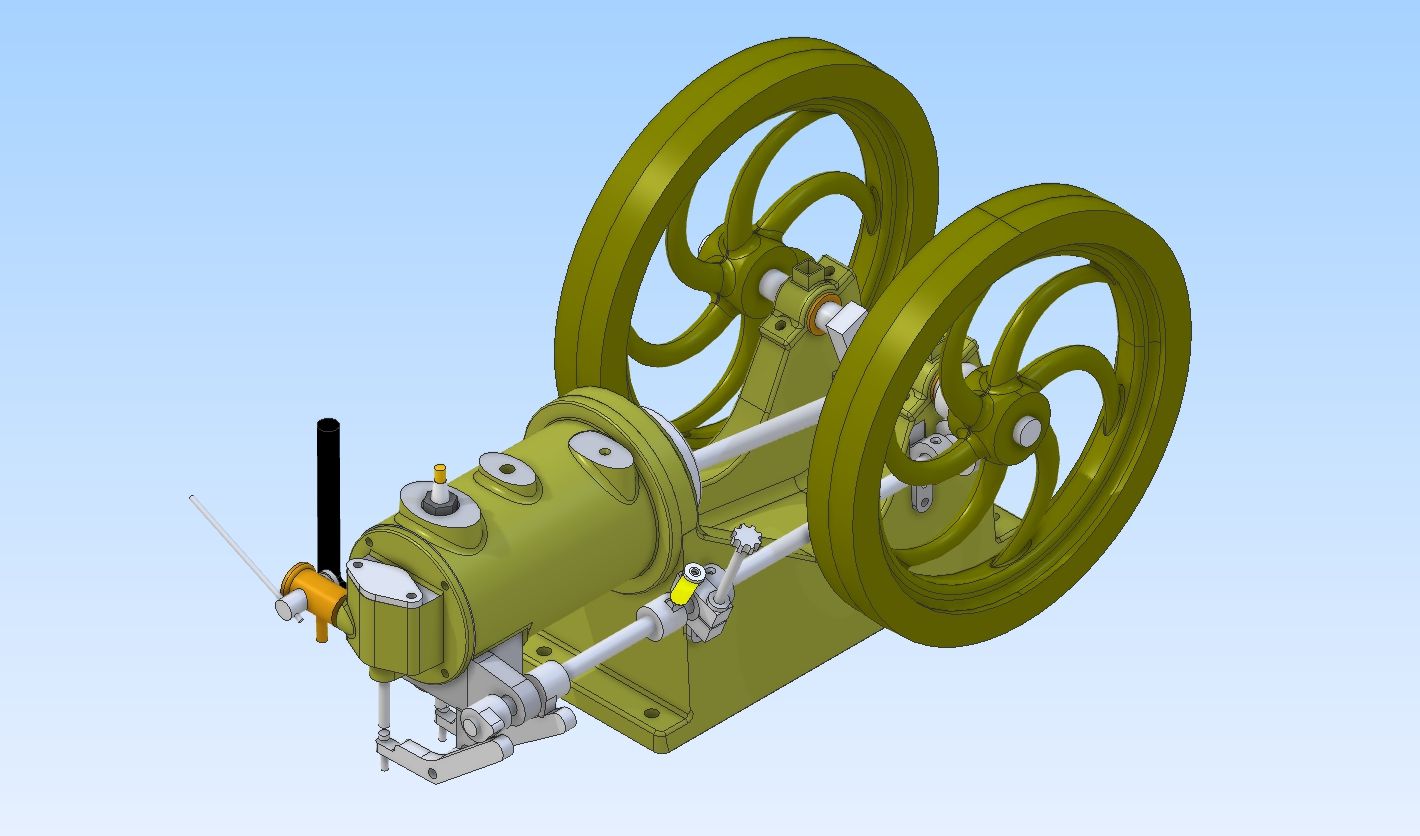

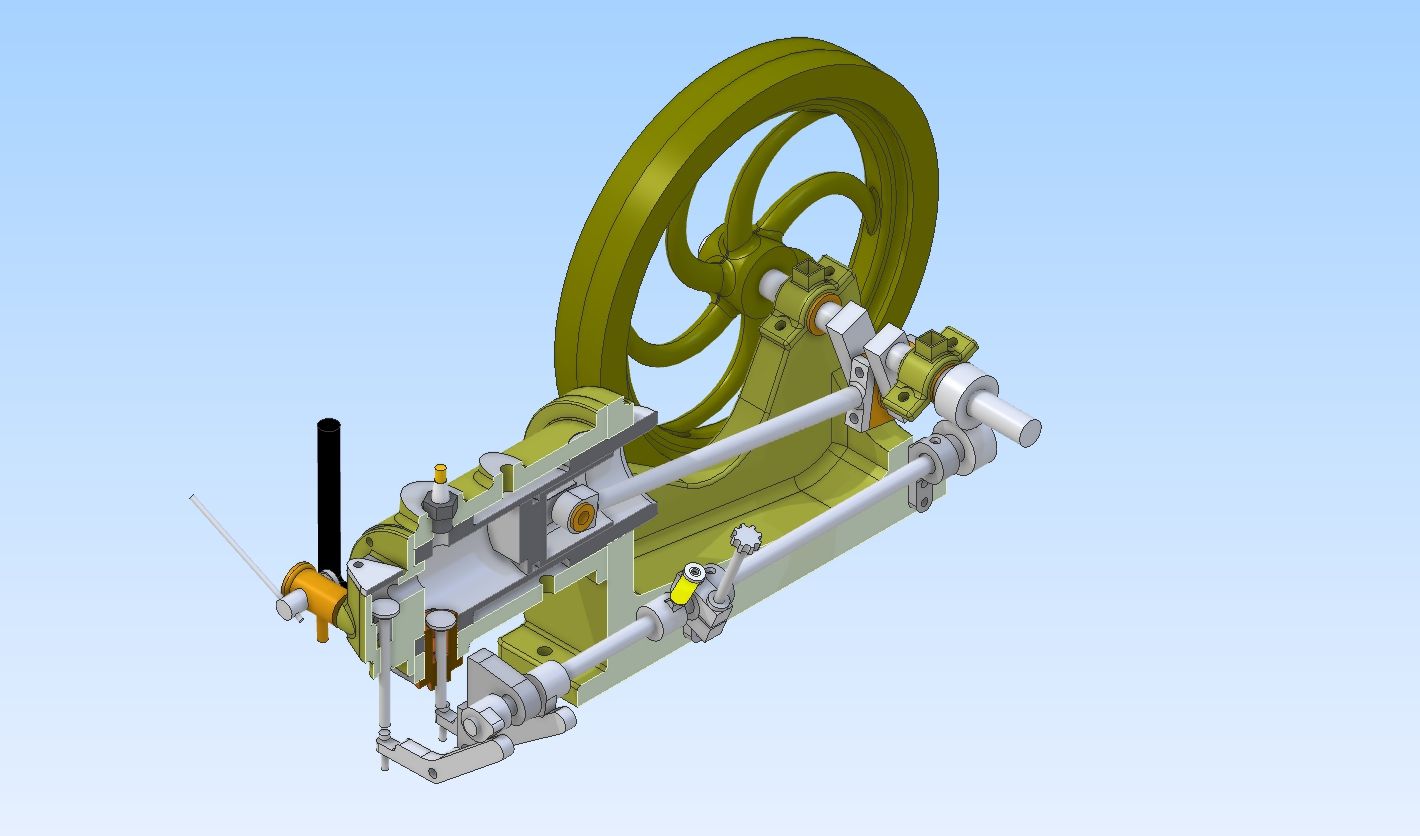

Gassie – national Gas Engine

Gassie – national Gas Engine

- This topic has 16 replies, 4 voices, and was last updated 23 May 2024 at 21:04 by

Diogenes.

Viewing 17 posts - 1 through 17 (of 17 total)

Viewing 17 posts - 1 through 17 (of 17 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Measuring a double Vee lathe bed Vee position

- Drawings for constructing a Rolling Road

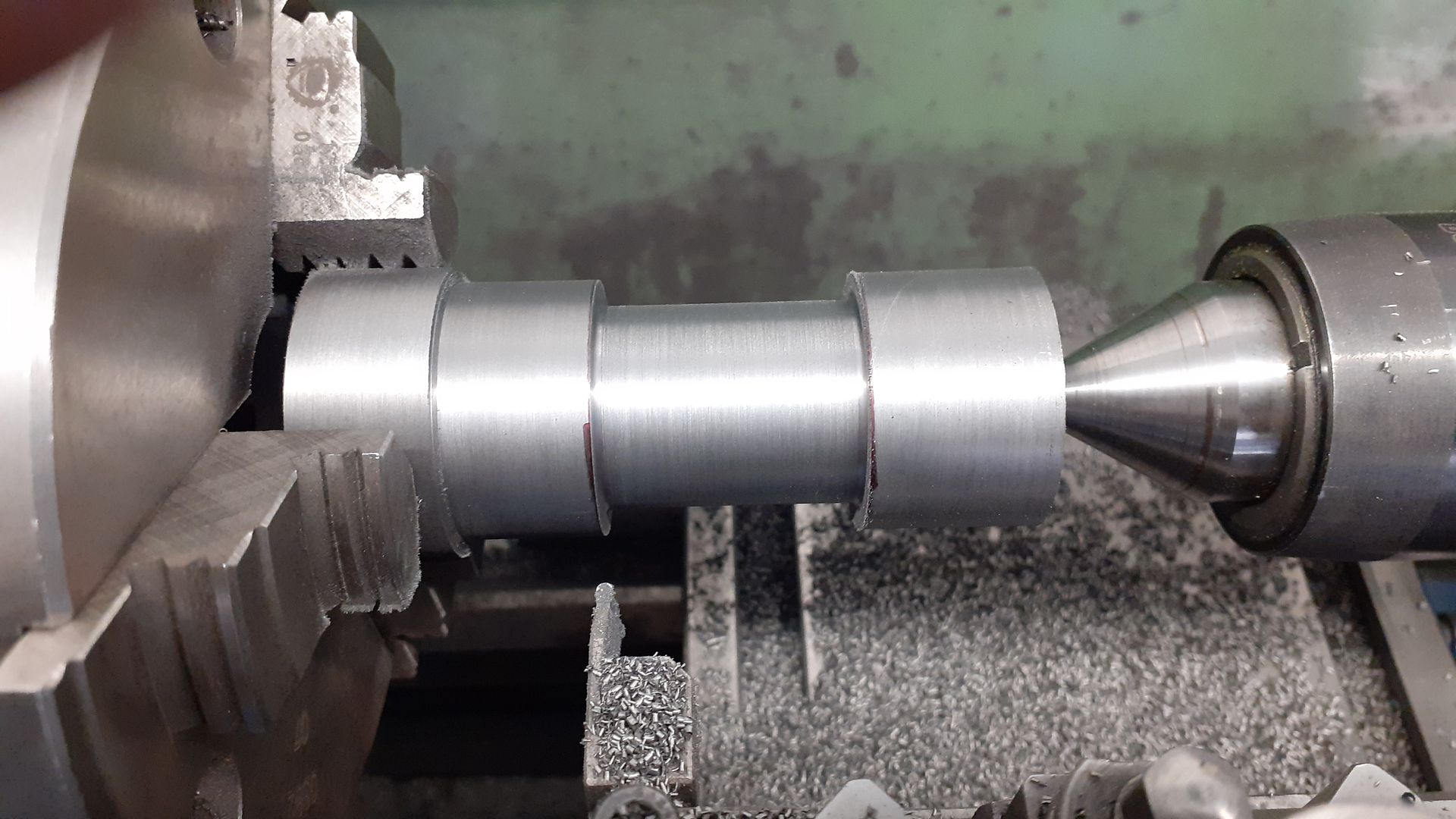

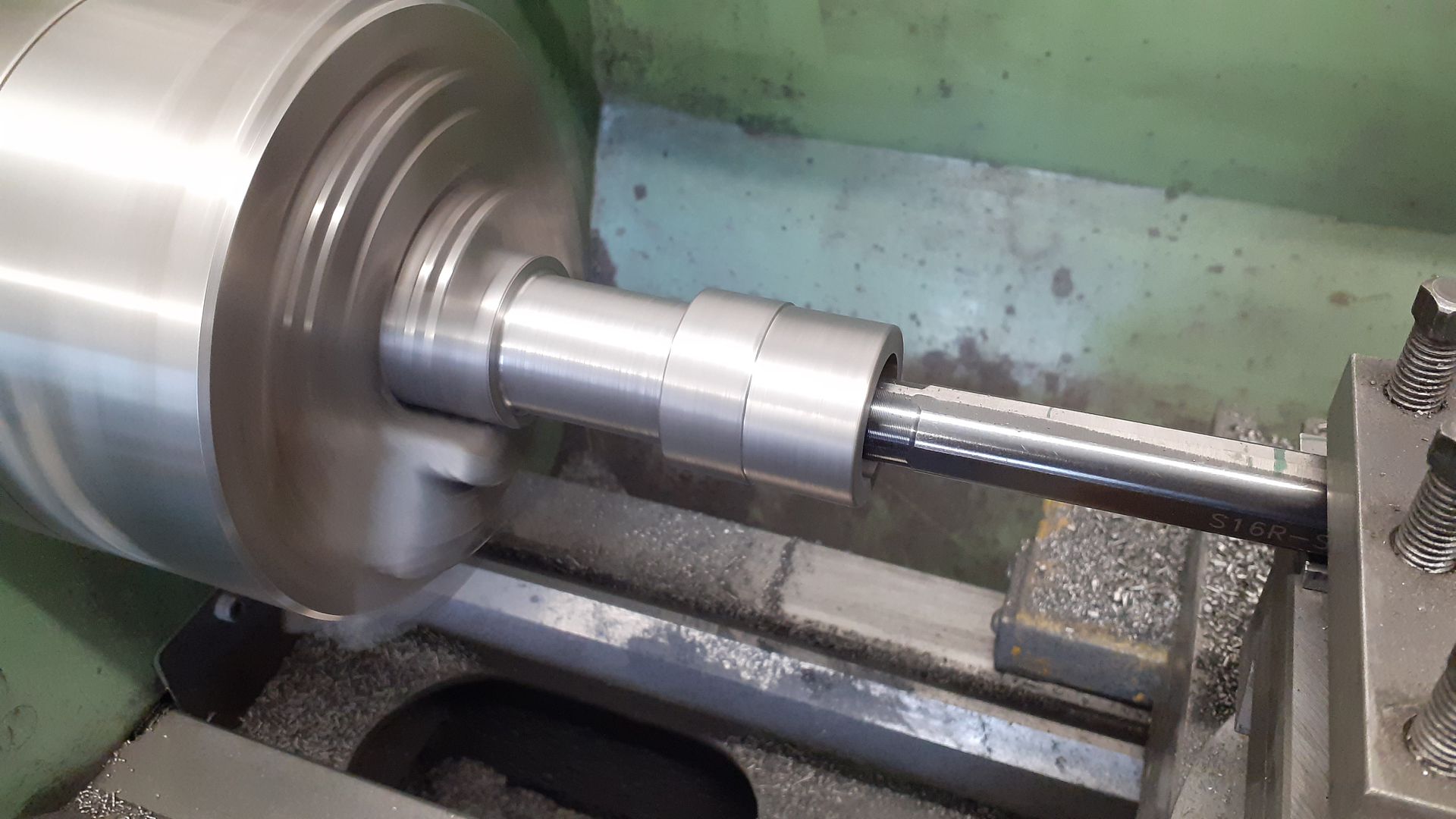

- Silver steel crankshaft

- Herbert B drill information?

- How many spokes do I really need?

- TurboCAD – Alibre File Transfers.

- Electronic leadscrew pitching error

- Advice to machine stationary engine base plate

- Boiler Design – issue 4765

- I’m Under Pressure