Hi Nick. yes I'm getting to like it, still won't be getting rid of the manual machines but the CNC does open up the options available and enable some projects that may not have seen the light of day be brought forwards.

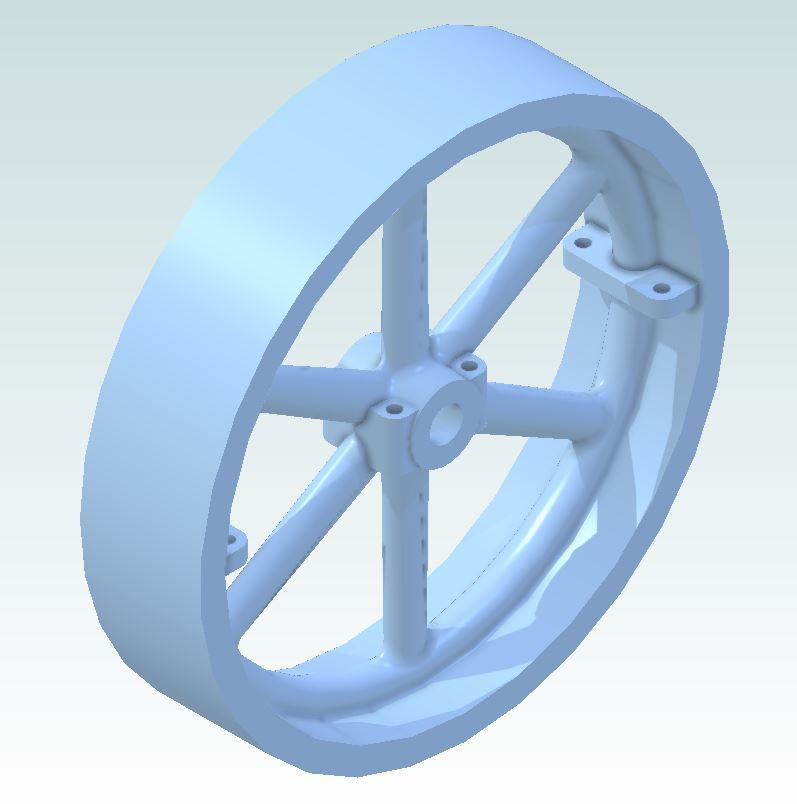

For the current engine that I'm working on I wanted a flywheel with quite a wide but thin rim and oval spokes tapering in width and thickness .

I have often used cast flywheels from other models but could not find anything to suit. Fabrication was an option but by the time I had sourced some thick wall tube, a disc to cut the spokes from and added something to beef up the hub area it worked out cheaper to go for the solid option so I ordered a 30mm length of 130mm diameter EN3 steel.

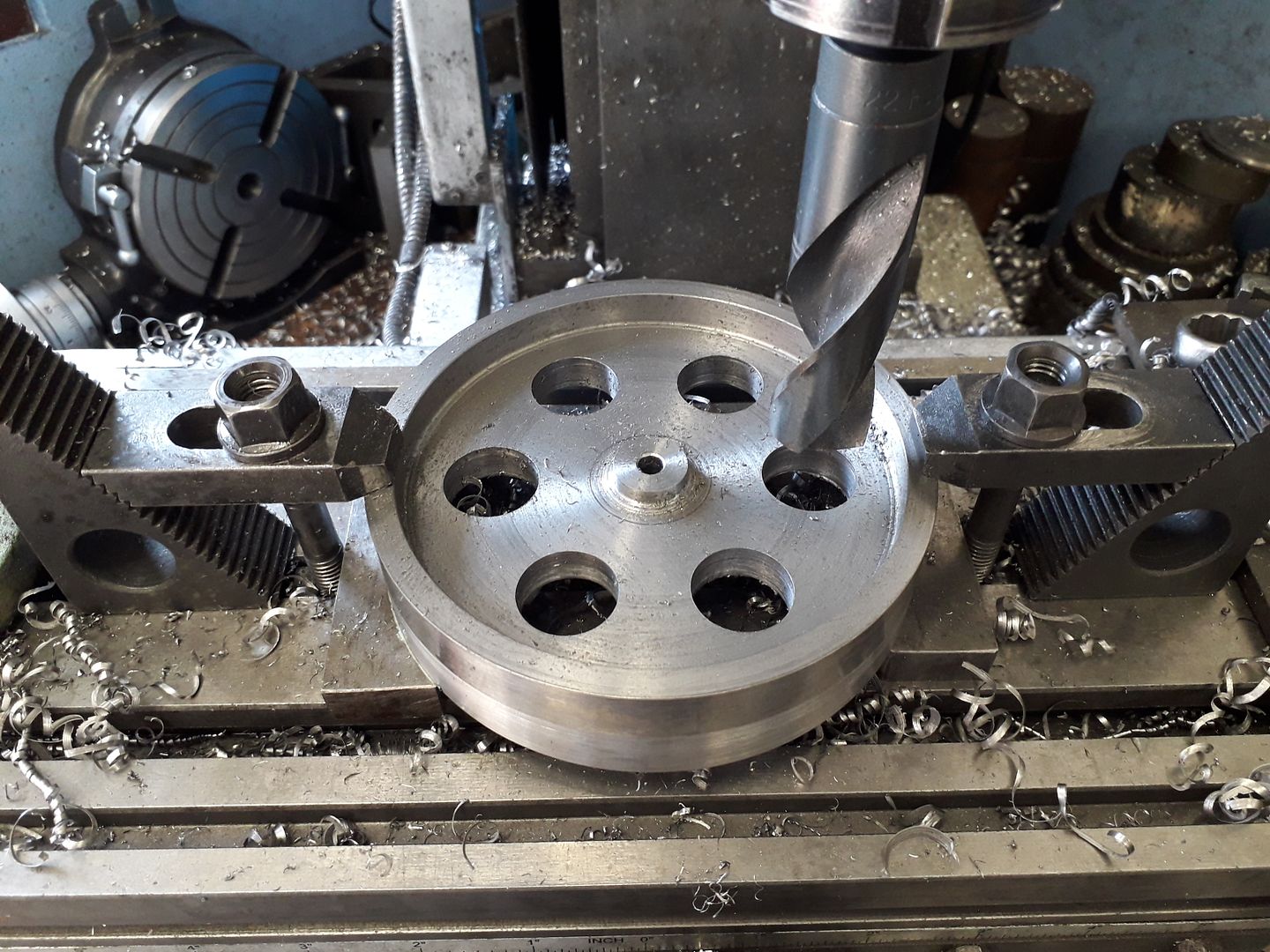

I decided to rough it out on the lathe and manual mill leaving material on all surfaces.

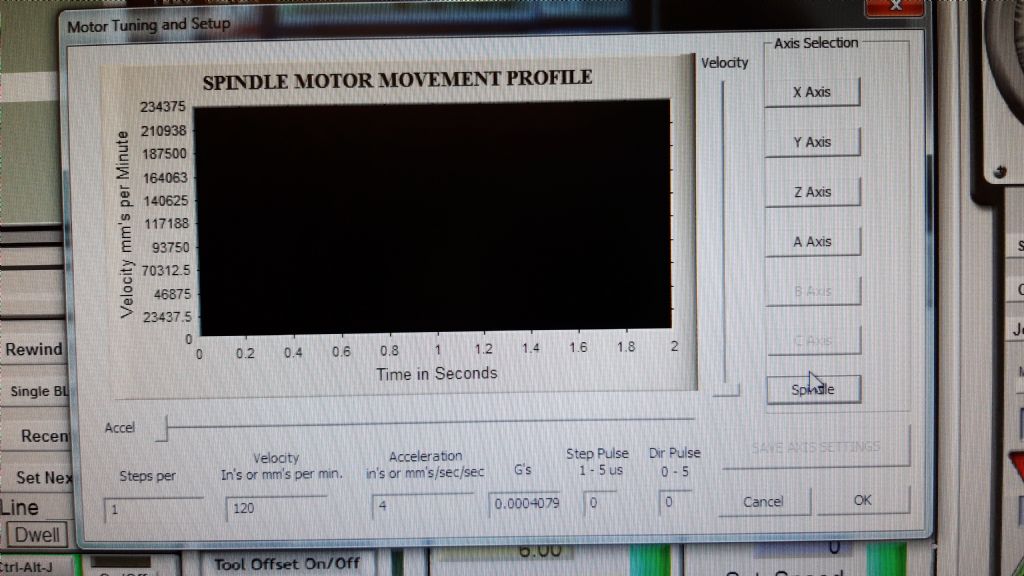

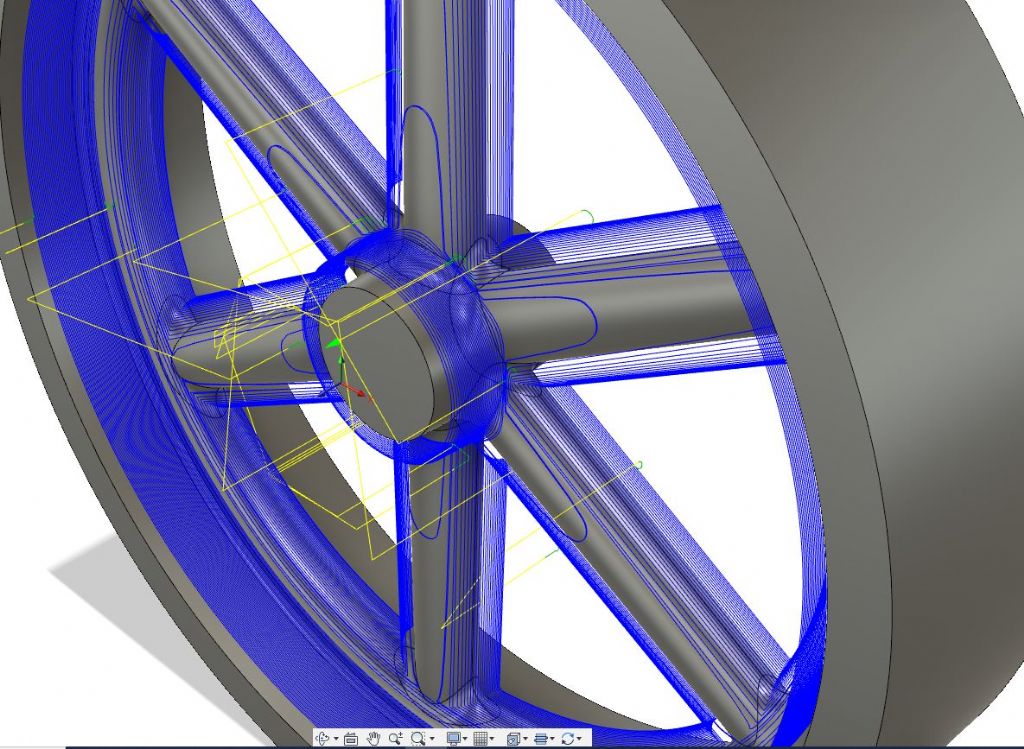

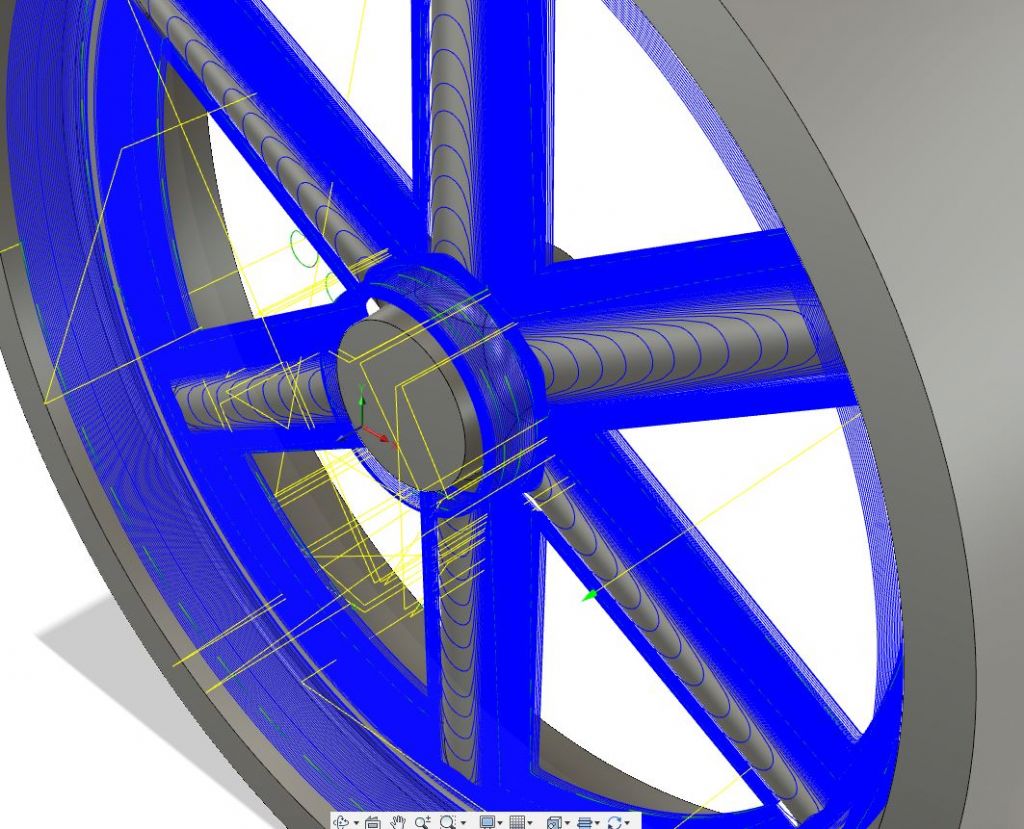

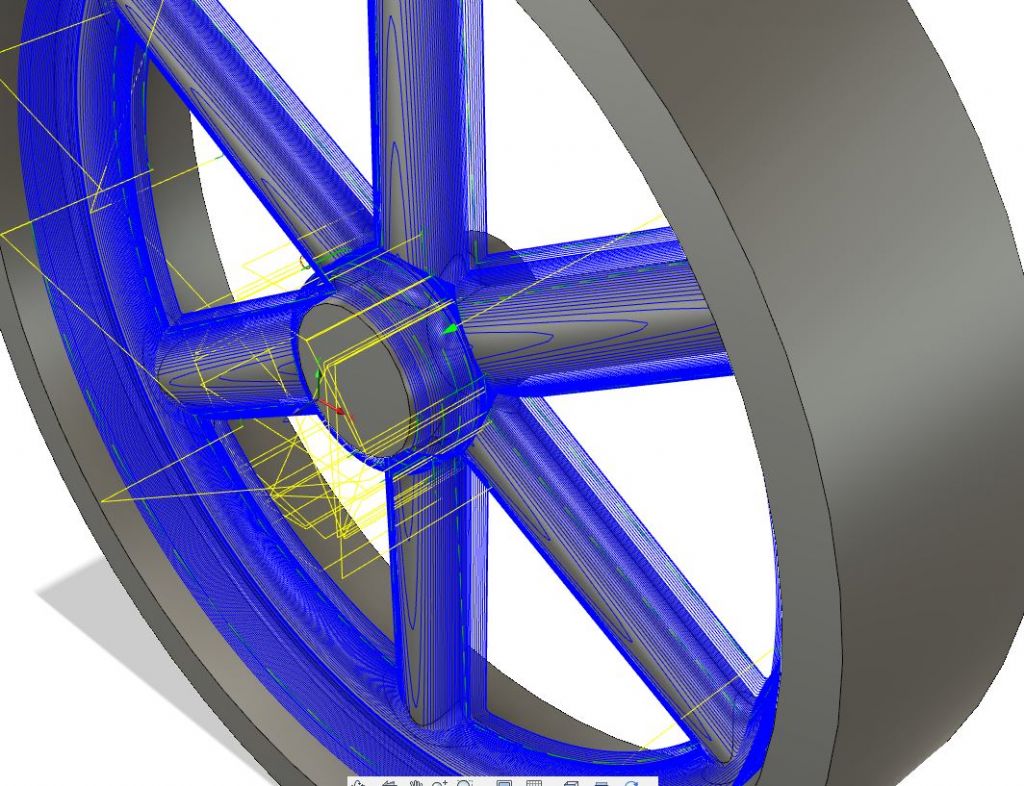

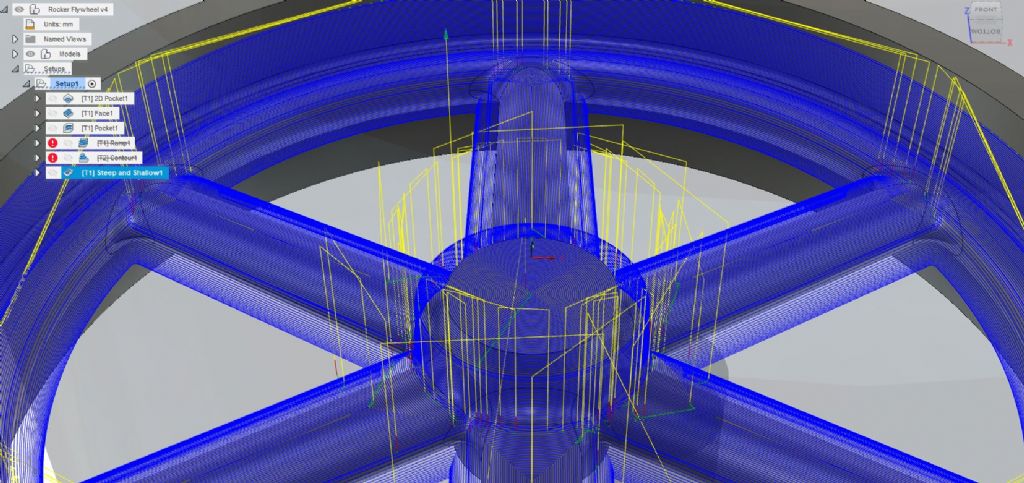

i did a dummy clearing program to mimic what I had done on the manual machines so that the CNC would not try and remove the metal again and then a clearing program was run starting at the height of the "disc" with a 1mm stepdown that left a finish like this

Then a finishing ramp with 0.2mm stepdown to give the draft angle to the inside of the rim and hub and then carry on down further to shape the spokes with a 6mm dia R1 tool

It then just needed a bit of fettling with the Dremel to blend the 0.2mm steps and I also added the bits to make it look like a 2 part flywheel.

A couple of coats of filler/primer and it's ready for colour.

Looks like I won't be needing many castings in the future.

Sarah F.