Hi Guys,

Thank you for the photographs of your spindle settings, your figures are very different to each others and also to mine as well. I've added a photo of mine below. The three machines are:

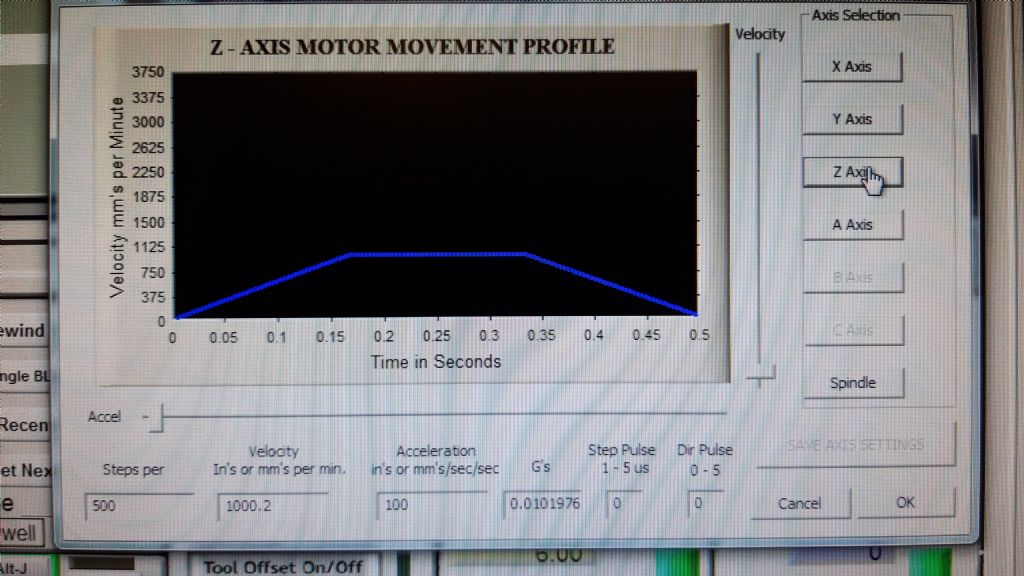

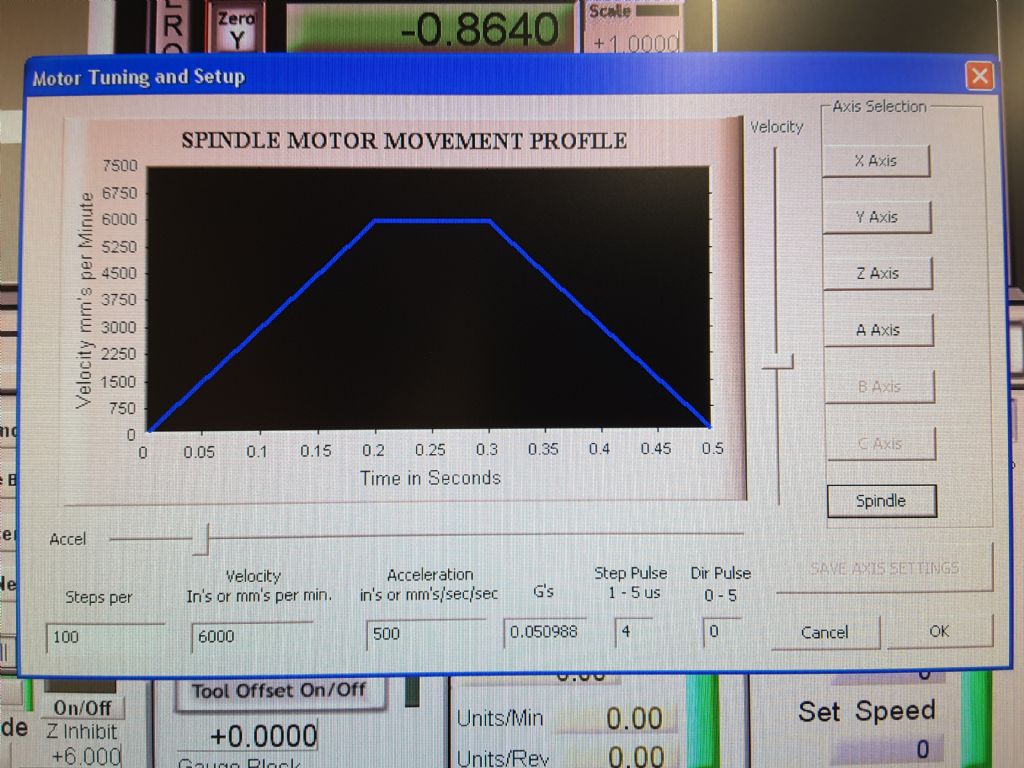

Steps per. Velocity. Acceleration

1. 120. 4

500. 1000.2. 100

100. 6000. 500

A few questions for you if you don't mind.

I understand what 'Steps per' do on the X, Y, Z axis relating to the stepper motors and ball screw drives, but what does it do on the Spindle Speed and why are our three machines so different?

Why are the Velocity and Acceleration figures also so different for the three machines?

I removed Mach3 and the Sieg setup files from my PC, then installed them again to make sure I had the default setting. If I go into the Motor Tuning screen, don't change anything and exit by just closing the X on the top right of the screen the Step Pulse won't change from 4us. However if I go into the Motor Tuning screen and click on the OK button to leave the screen, then when I go back into the Motor Tuning screen again it has changed to 3us. It will retain a value of 3us and 5 us.

When it does change the Step Pulse to 3us, or a value of 5us, this changes the value for the X, Y and Z axis as well and changes how the axis are driven. Will driving the X, Y and Z axis at 5us cause any problems?

I can match the measured and demanded spindle speeds if I do change the Step Pulse to 5us, but I'm wary of changing bits I don't really understand.

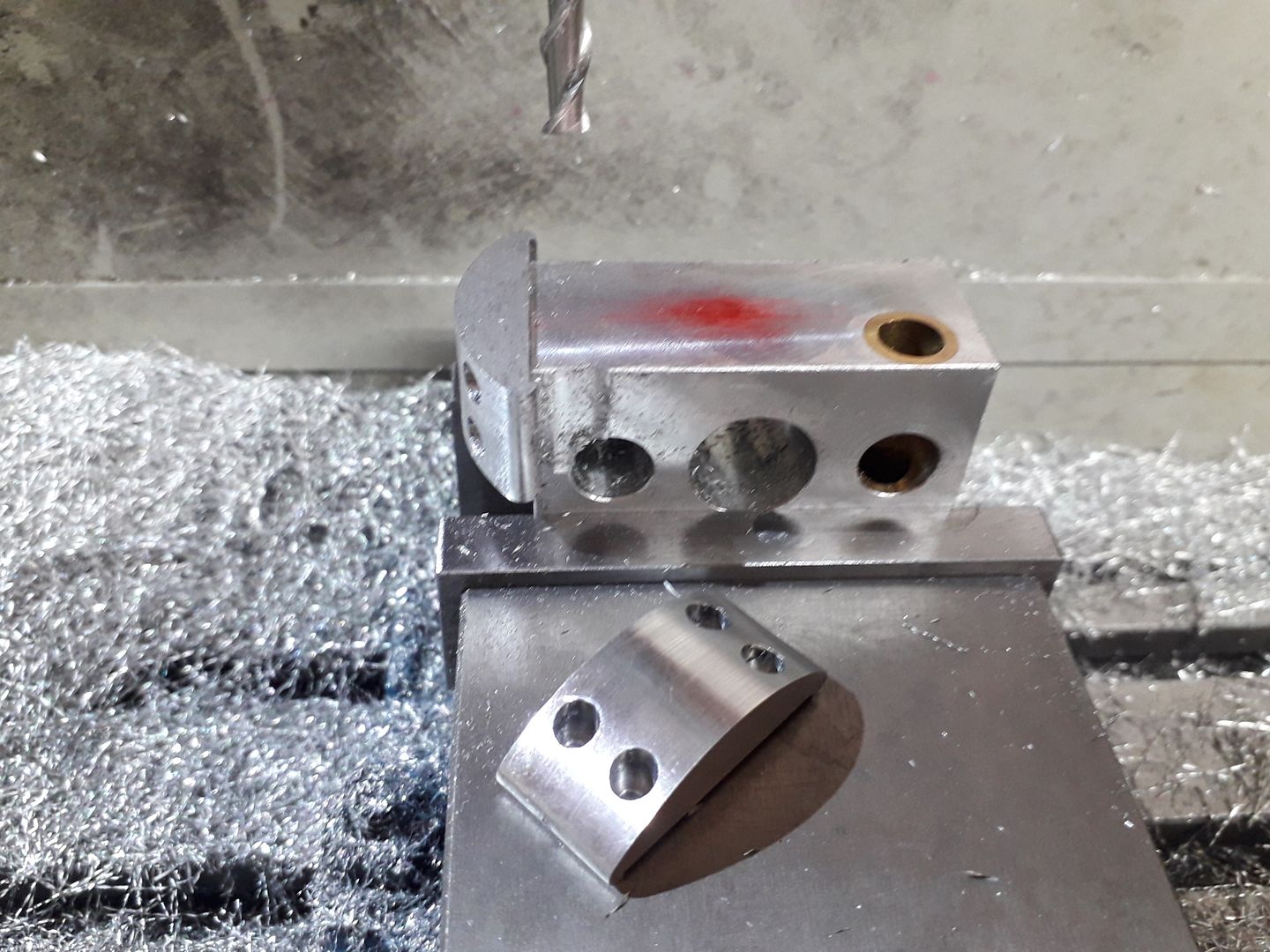

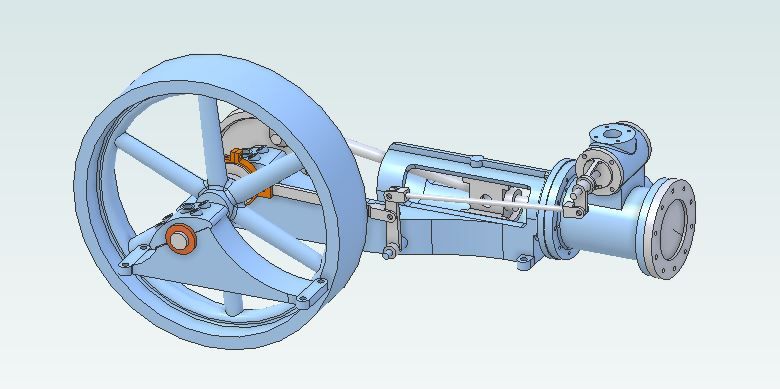

Thanks for the video's and pictures of your work on your machining, giving me a good idea of what to do. I'll post some of mine soon hopefully. I wouldn't have thought of fixing a bit to be machines to the side of a chunk of aluminium, it will make a bit I need to machine a lot easier thanks.

I appreciate your help, hope I'm not asking too many questions, I'm just eager to learn.

Best wishes,

Sarah

Edited By Sarah on 12/04/2020 09:38:58

Edited By Sarah on 12/04/2020 09:41:50

Sarah F.

![20200410_103408[1].jpg 20200410_103408[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/856543.jpg)

![20200410_095720[1].jpg 20200410_095720[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/856540.jpg)