Hi Ron, Yes generally the larger the radius of teh cutter the smoother the finish will be but there are other things to consider.

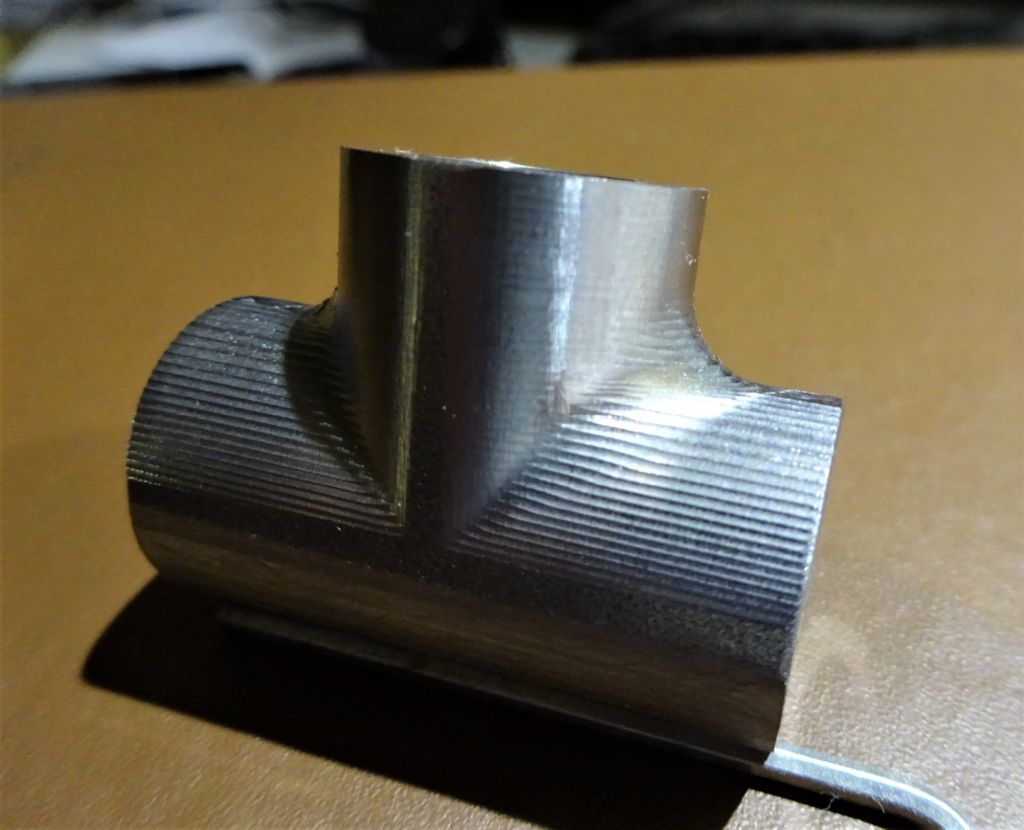

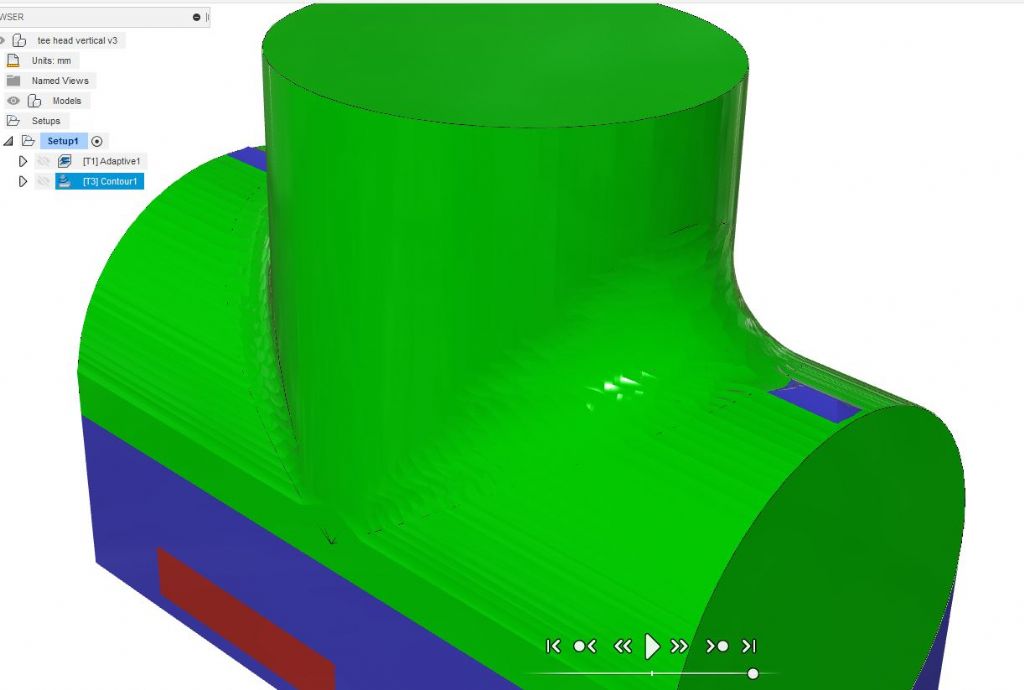

Firstly this shows the part enlarged in the CAM program as I cut it with the 6mm dia 1mm corner radius cutter, the couple of odd blue bits are in excess of 0.1mm of finished size, all the green is withing 0.1mm of finished size so not really that rough at least in my book and as I want to simulate a casting a bit of variance when hand finished will be a bonus.

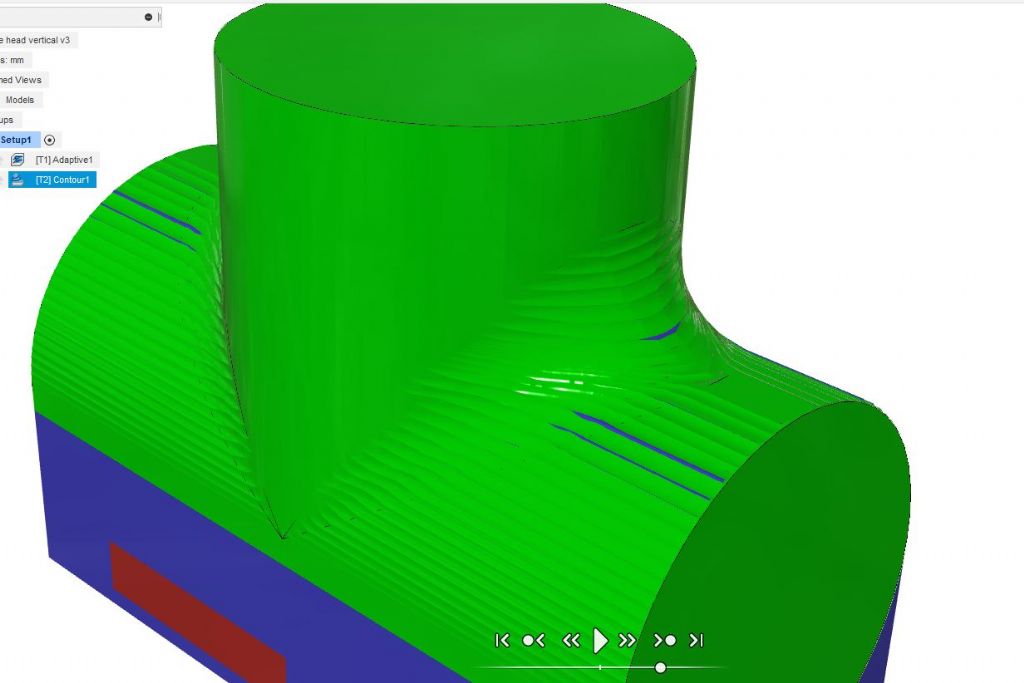

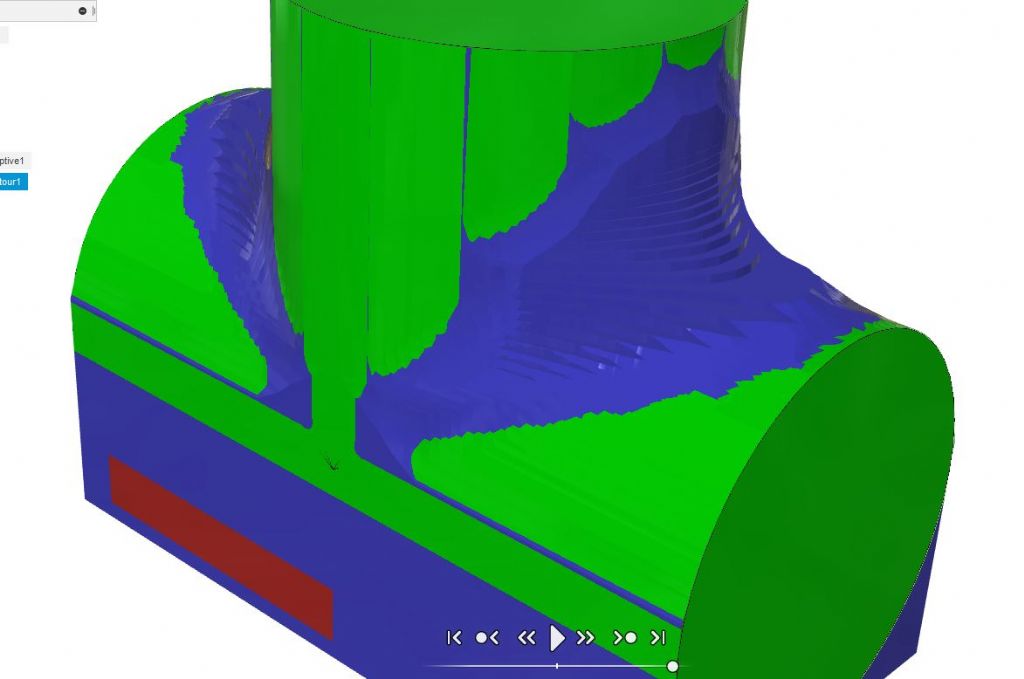

One simple way I could get it smoother is to reduce the step down between cuts, I did it at 0.5mm stepdown but this pic shows it done at 0.25mm stepdown, blue has gone and the green surfac elooks smoother but it would take twice as long to machine

If I now run it with a 6mm ball nose cutter the green surface is even smoother but there are two isssues. Firstly on the more horizontal surfaces where the middle of the cutter is doing the work the cutting edges are not moving very fast so feeds may need to be slower and secondly as a lot of ball nose cutters are 2 flute then if the chip load is to be kept the same you would need to feed at half the speed so again twice as long to machine though I do have some 4-flute ball ended cutters that would be able to be fed as fast. Ignore the blue bit as I did not fully alter the CAM to suit the ball ended cutter but green is even smoother.

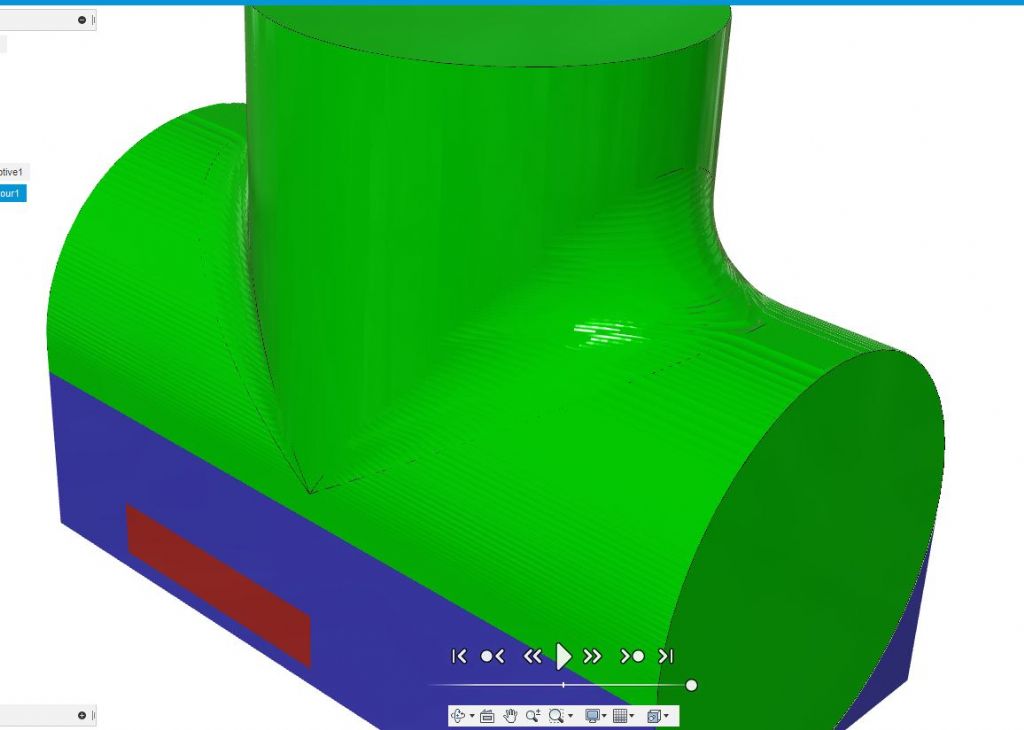

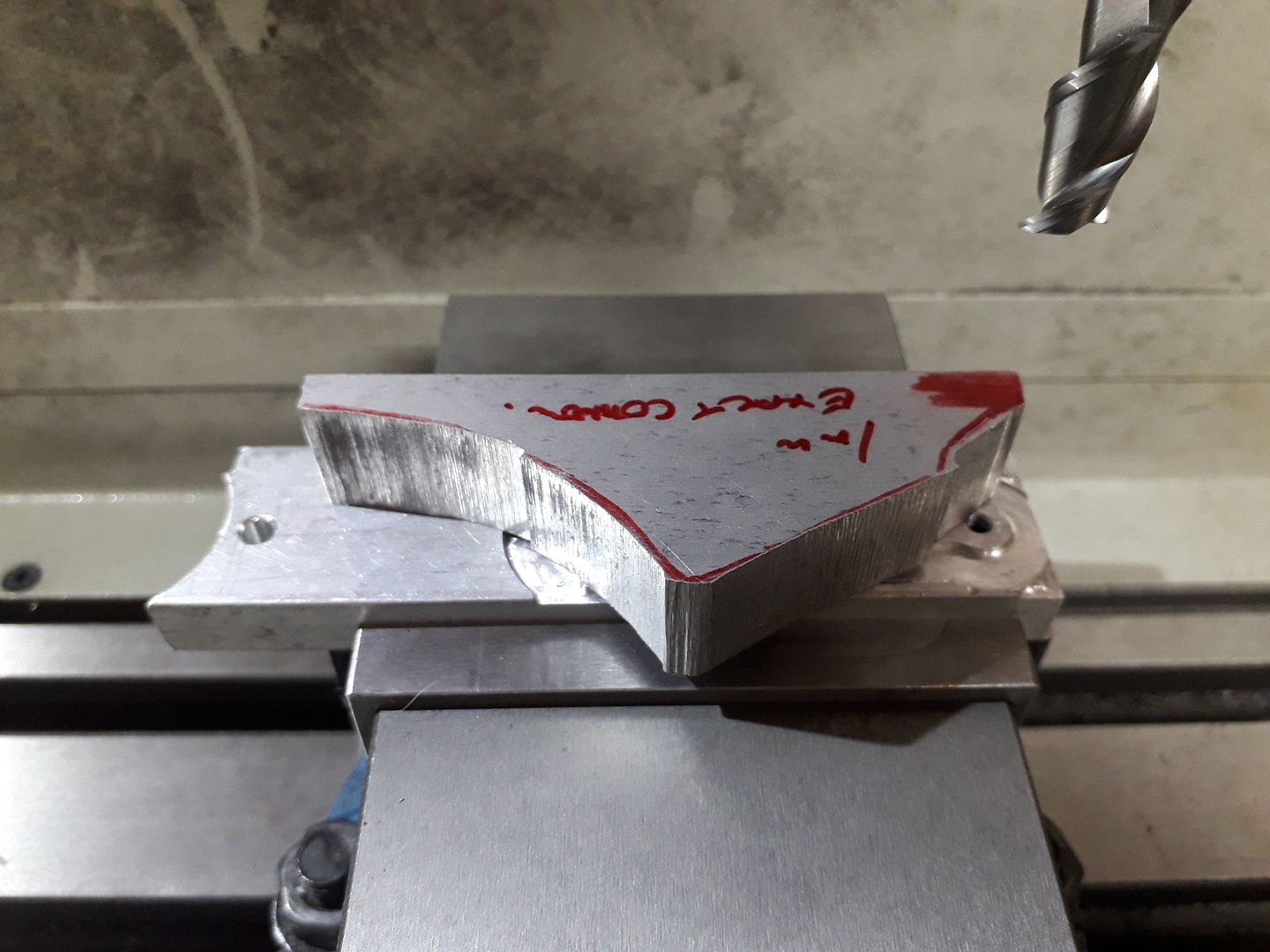

Though you do have to be careful how large a radius you go for as it may not be small enough to get into the corners and to machine down as far as I have you would have more of the cutter below the widest point of the work so less to hold in the vice, this is with a 20mm ball nose which leaves a lot in the corners and the blue line along the edge is where I can't get to without hitting the vice

So lots of factors to think about and that also depend on the cutters you have and how long the machine will be tied up which affects commercial users more than us hobby users

Sarah F.