Ron, that was one of the things that had put me off CNC in the past, all this talk of writing G-code and I also remember watching a couple of guys on the SMEE stand at an exhibition spend ages just trying to machine a simple flat surface that I could have done in a fraction of the time manually.

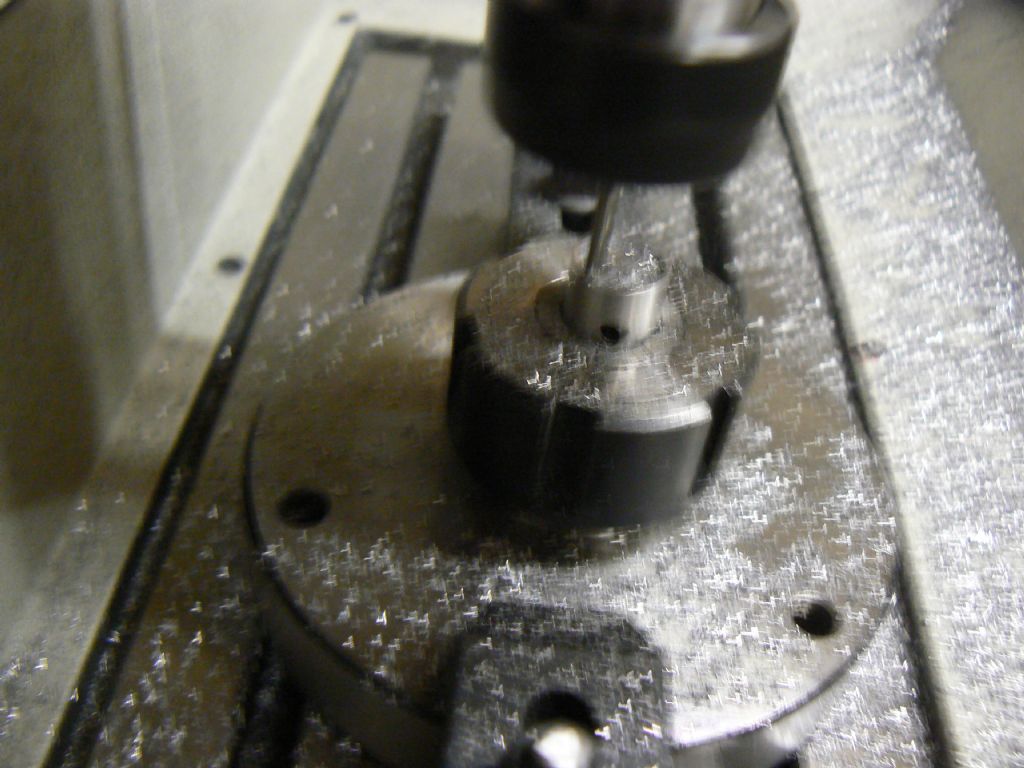

However CAM has come to the rescue and will produce all the code for me. I do need to enter thing like type of tool and how fast I want it to run, DOC etc and one or two other things. It is then a question of deciding on the type of operation and just clicking on the overall shape for things like the contour or the holes for drilling and even then I can just click one and tick a box so it selects all holes of the same size. There are several other tweaks that can be used to suit the part in hand but it works out all the paths from the info entered.

There is an extensive tool library with preset speeds and feed for various materials, so just select a tool and adjust the parameters to suit which can be saved

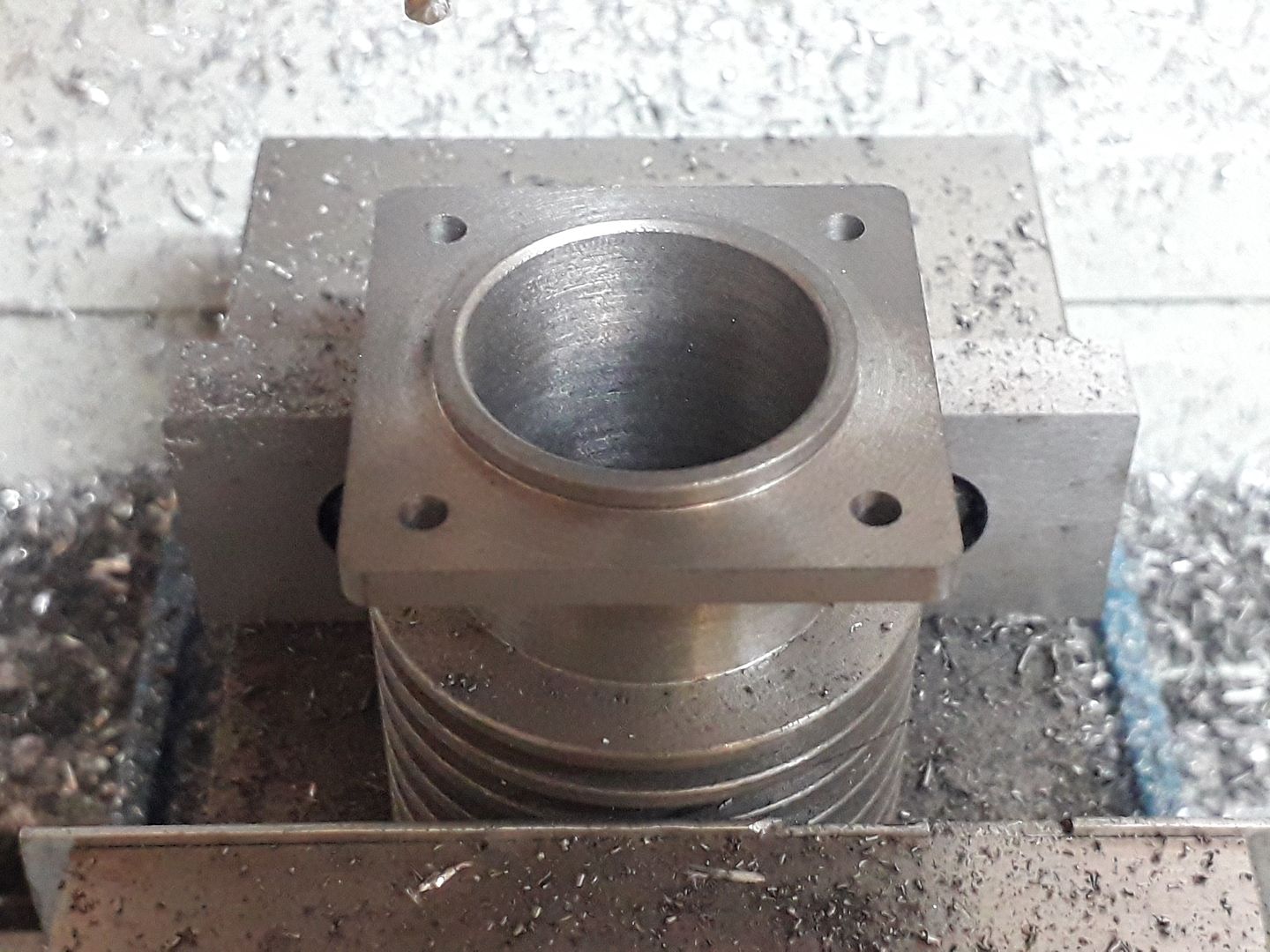

There are six basic operations to form that part

1. 3D adaptive clearing. This roughing cut removes the bulk and leaves 0.5mm for later finishing

2. 2D contour . Finish cut around the tops of the two valve guides

3. 3D contour this refines the overall curved shape in shallow steps

4. Horizontal contour which finishes the flat horizontal areas of the flange and skims the top of the valve guides

5. 2D Vertical contour which finishes the vertical faces of the oval flanges each side

6. Drilling

Probably took me 1/4hr to do the Cam but would be far less if I knew what I was doing then click a button and the machine spits out just less than 29,000 lines of G-code. Other facts you may be interested in is that the cutters travelled a total of 29.18m and removed 65.1% of the original block in 1min 14sec.

Edited By JasonB on 28/07/2019 17:08:08

Sarah F.