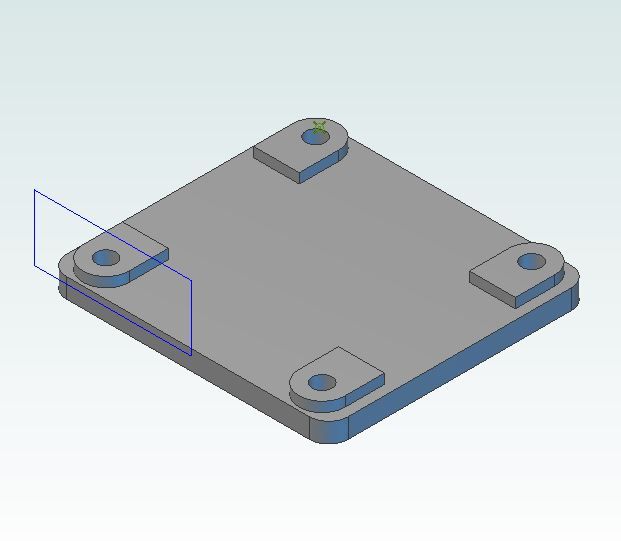

Sorry john missed your post yesterday, Drawn in Alibre then CAM in F360 using an exported STEP file.

A post on another forum brought up the subject of the "Star Wheel" used on the Alyn Foundry "Sphinx" engine which is an alternative to timing gears and operated the exhaust valve on alternate strokes. A casting is supplied but the latest batch are not upto the usual standards that Alyn were well known for so I happened to mention that if my casting was not usable then it would be something worth trying to cut on the CNC. Well that was all it took to get me trying it out.

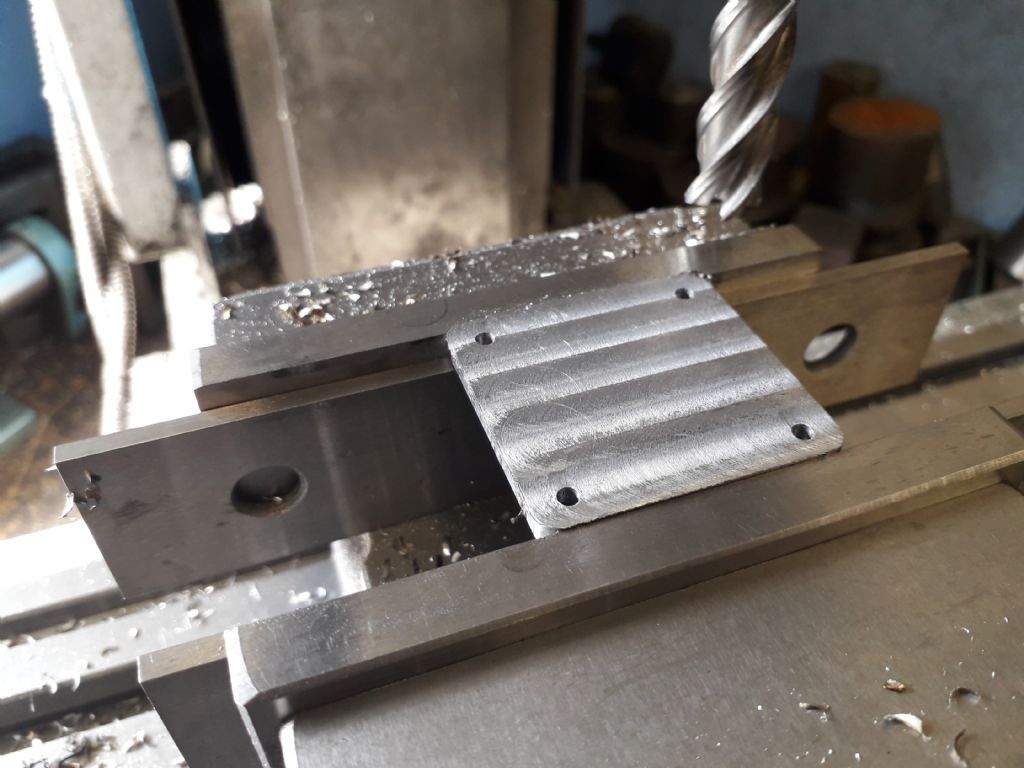

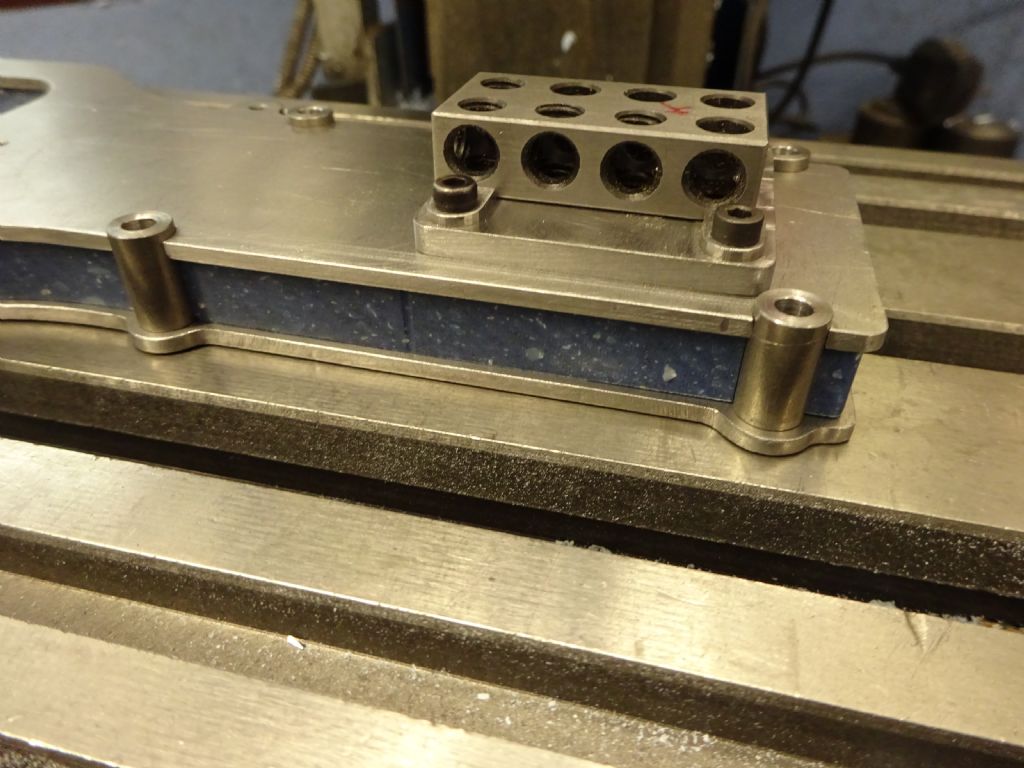

Video firstly shows the adaptive clearing, I speeded things up 20% after filming so that was a 6mm Carbide 3-flute cutter at 3600rpm, 150mm/min, full 8mm height cut with a conservative 0.25mm DOC. I went with Andrews suggestion of cutting both ways which reduced the time quite a bit. It was cutting very nicely and I did not bother with brushing on anymore suds which only seemed to make the swarf stick to the work.

There is then a clip of a 4mm dia cutter clearing further into the internal corners which went well but during the final contouring cuts it went pop which almost made me go poop. It was a cheapie and at a cut height of 2D I was probably asking for trouble. I had drawn in a corner radius of 2.1mm but that probably should have been more.

Video ends having reverted back to the 6mm cutter for the final contour cuts which I slowed down so that it would not chatter in the corners.

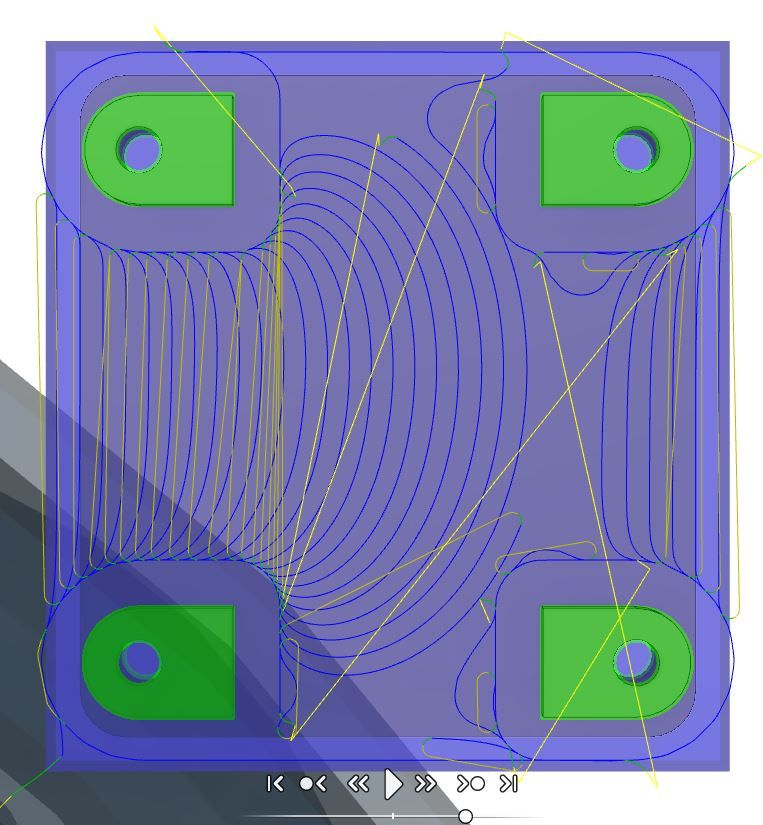

This pic shows the star wheel after the first clearance cuts, you can see the faceting of the curves.

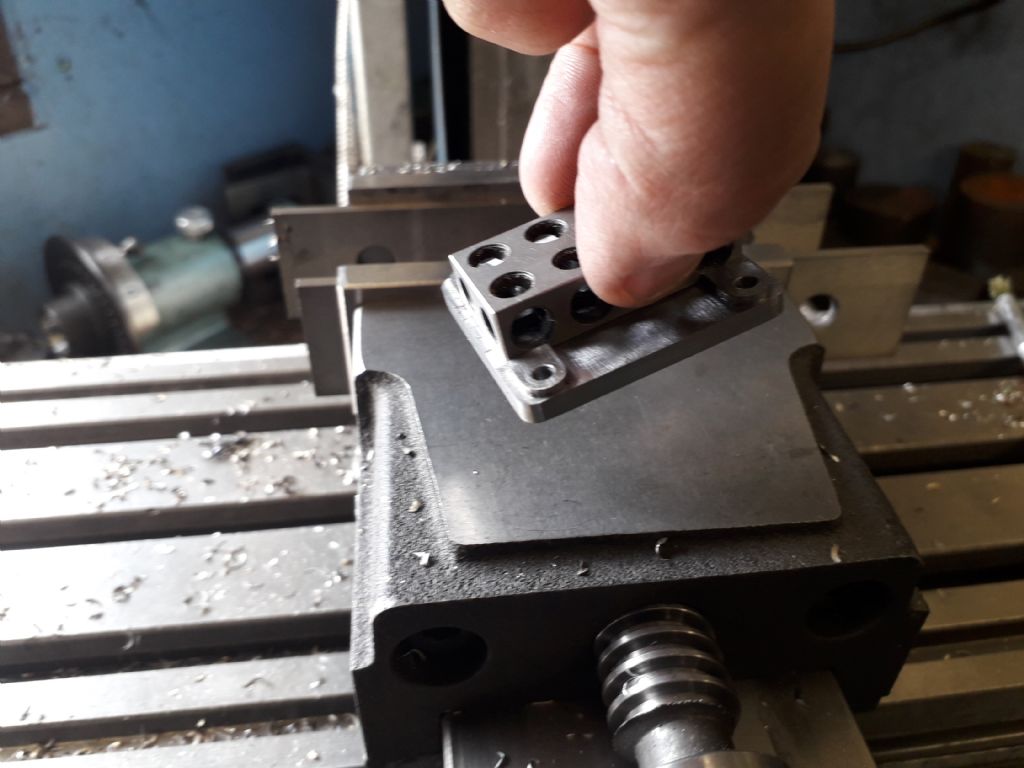

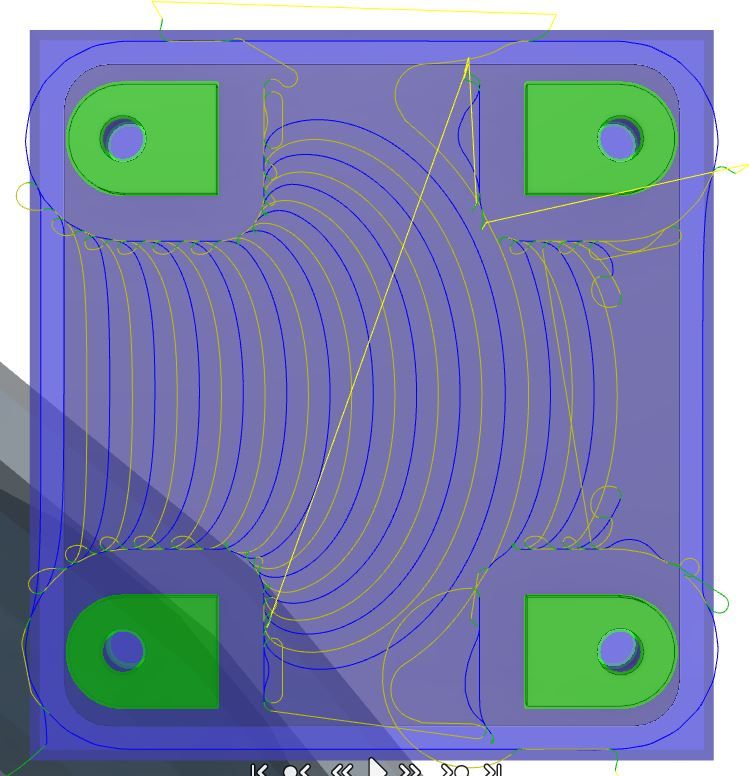

This is after all the milling where the curves flow better. Interesting to see the three height bands left by the tool, although it has not done much they show the wear from the 2.5mm plate, the 1/4" flat bar and the best finish at the top which can be seen better in the video is unused edge.

All that remained was to file out the internal corners, casting for the hell of it!

Edited By JasonB on 18/04/2019 15:22:36

Sarah F.