I had originally said that I would draw up the flywheel for Graham Corry's 1/3rd scale Brayton Readymotor with the intent that he would get patterns 3D printed but costings were coming in quite high and he did not get much joy looking for someone who could do a one use CNC router cut foam pattern. So I said leave it with me and I will see what I can do.

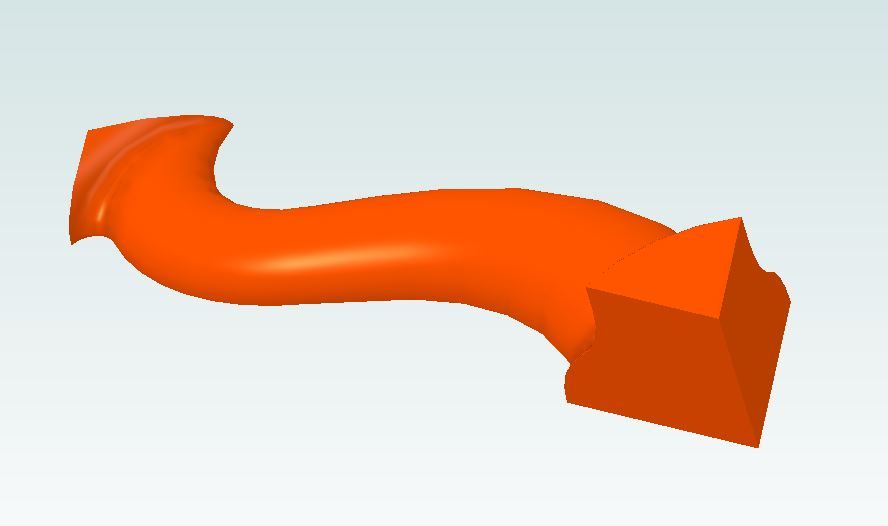

At just under 400mm diameter I would not stand a chance of cutting it in one on the KX3 but did think about cutting the spoke area within the rim which would still have entailed doing it in 3 sections but not easy to accurately reposition between cuts. Another option was to make individual half spokes that could be built into a separate rim and that is what I went with.

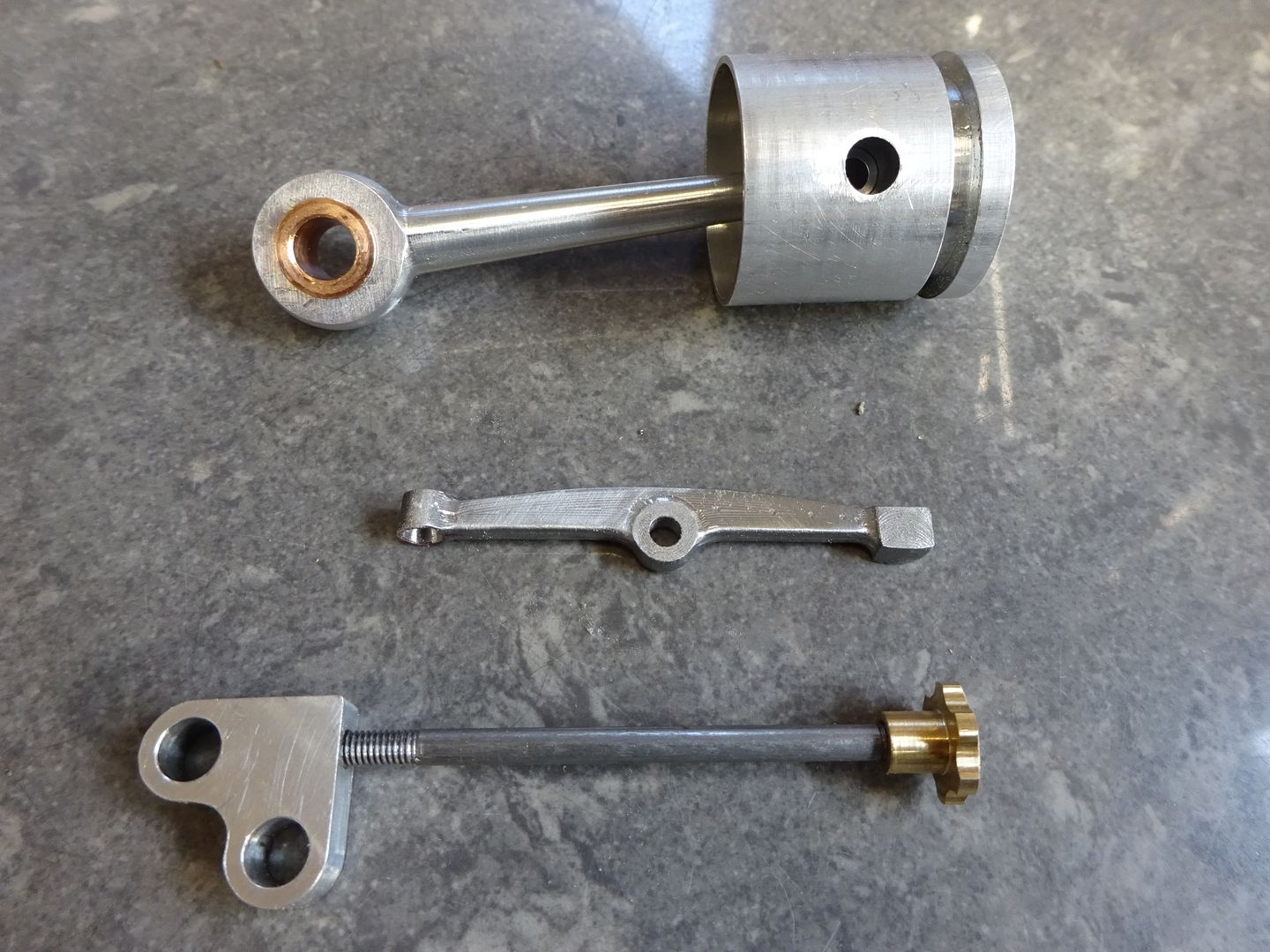

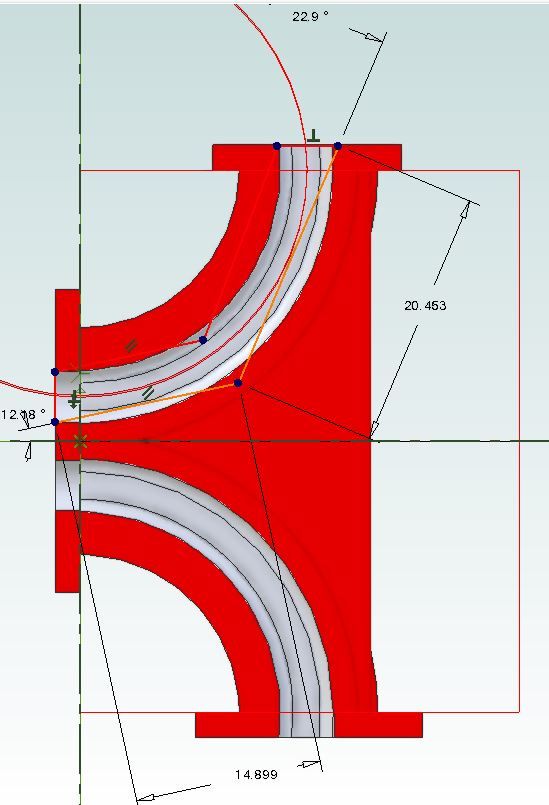

First most of the pattern was cut away in Alibre to leave a single spoke with a 60degree segment of the hub and the fillets where the spoke joins the rim.

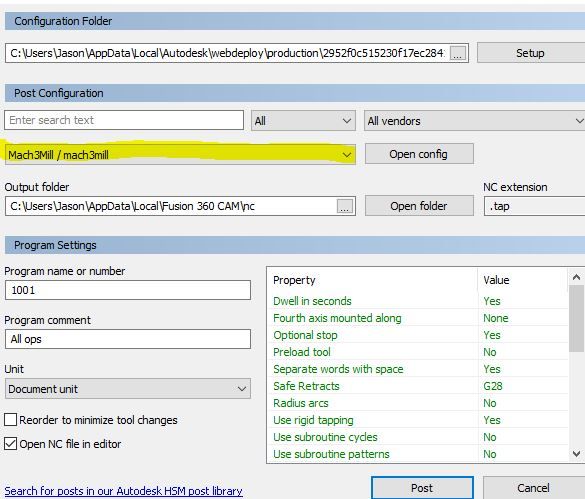

I used F360 to do the CAM and this was the first time I had drawn the stock rather than just letting the program suggest a cube it would fit into which allowed me to orientate the stock to the best position to suit the spoke shape and keep the overall size as small as possible to save machining time.

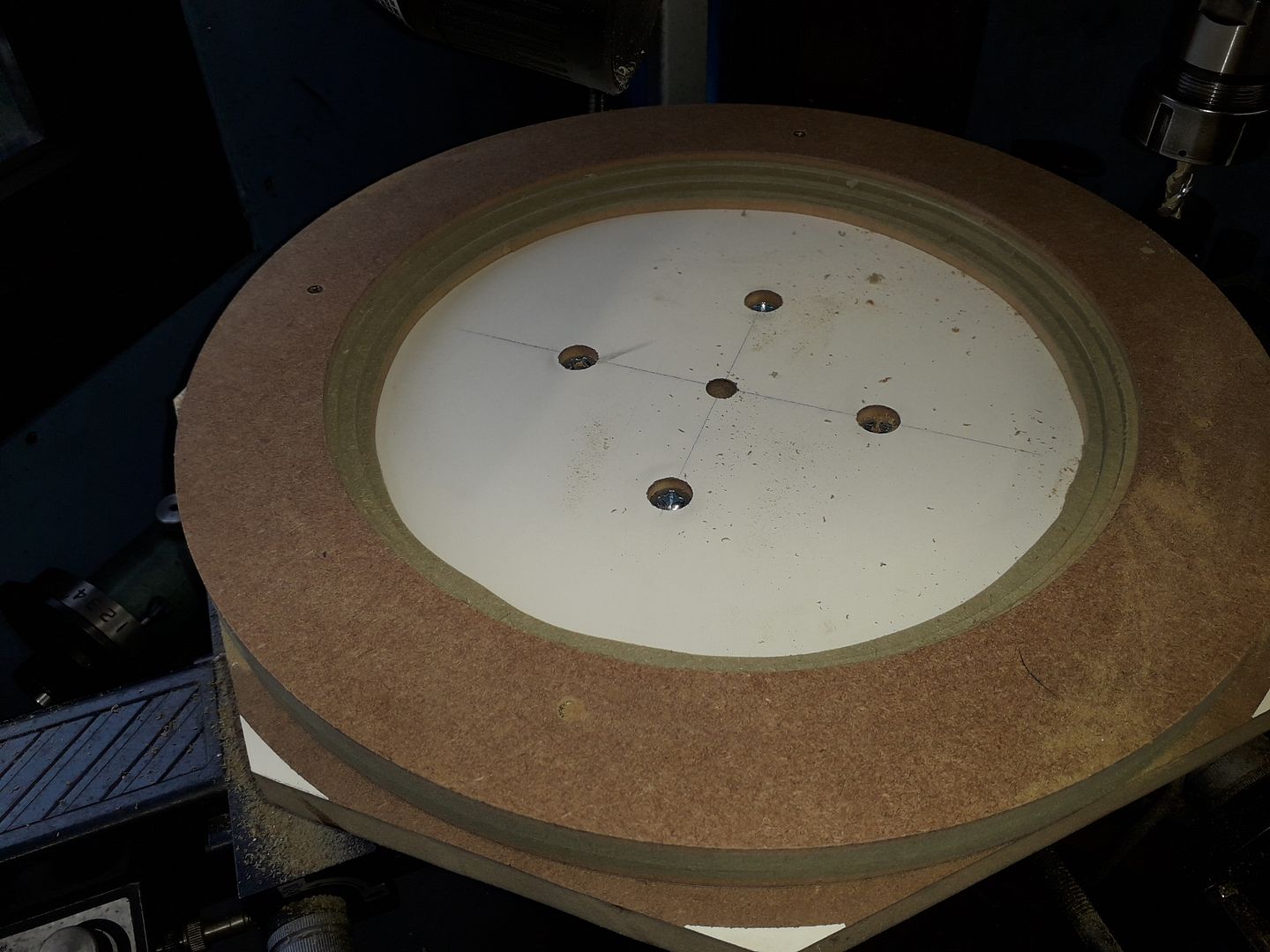

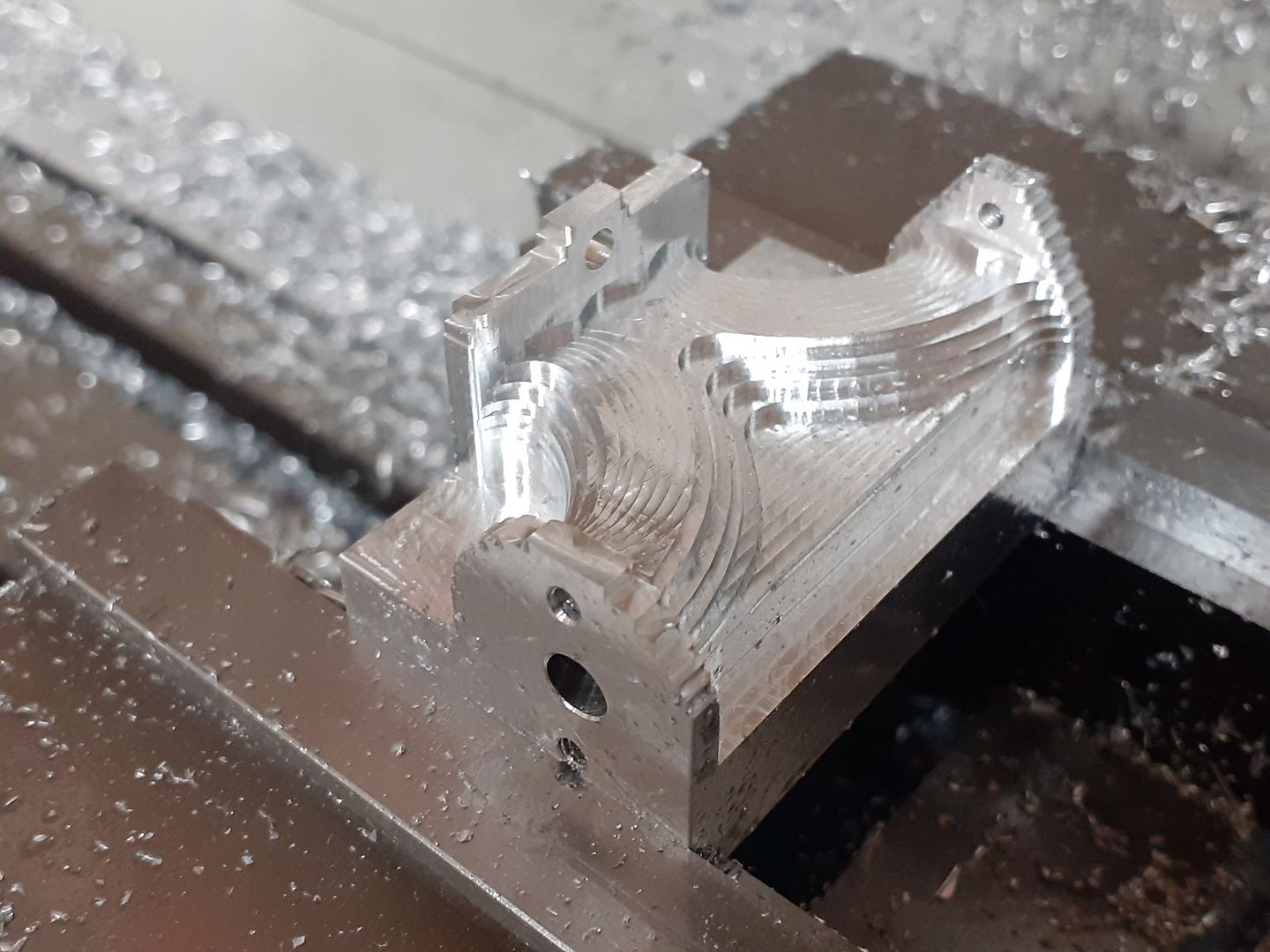

The stock was glued to a piece of MDF which in turn was held in the vice. I put a layer of copy paper between the two glued surfaces which makes it quite easy to separate the two as the paper just delaminates with a tap of a chisel on the joint line. This is the job straight off the machine

![20200727_122720[1].jpg 20200727_122720[1].jpg](data:image/svg+xml;base64,PHN2ZyB3aWR0aD0iMSIgaGVpZ2h0PSIxIiB4bWxucz0iaHR0cDovL3d3dy53My5vcmcvMjAwMC9zdmciPjwvc3ZnPg==)

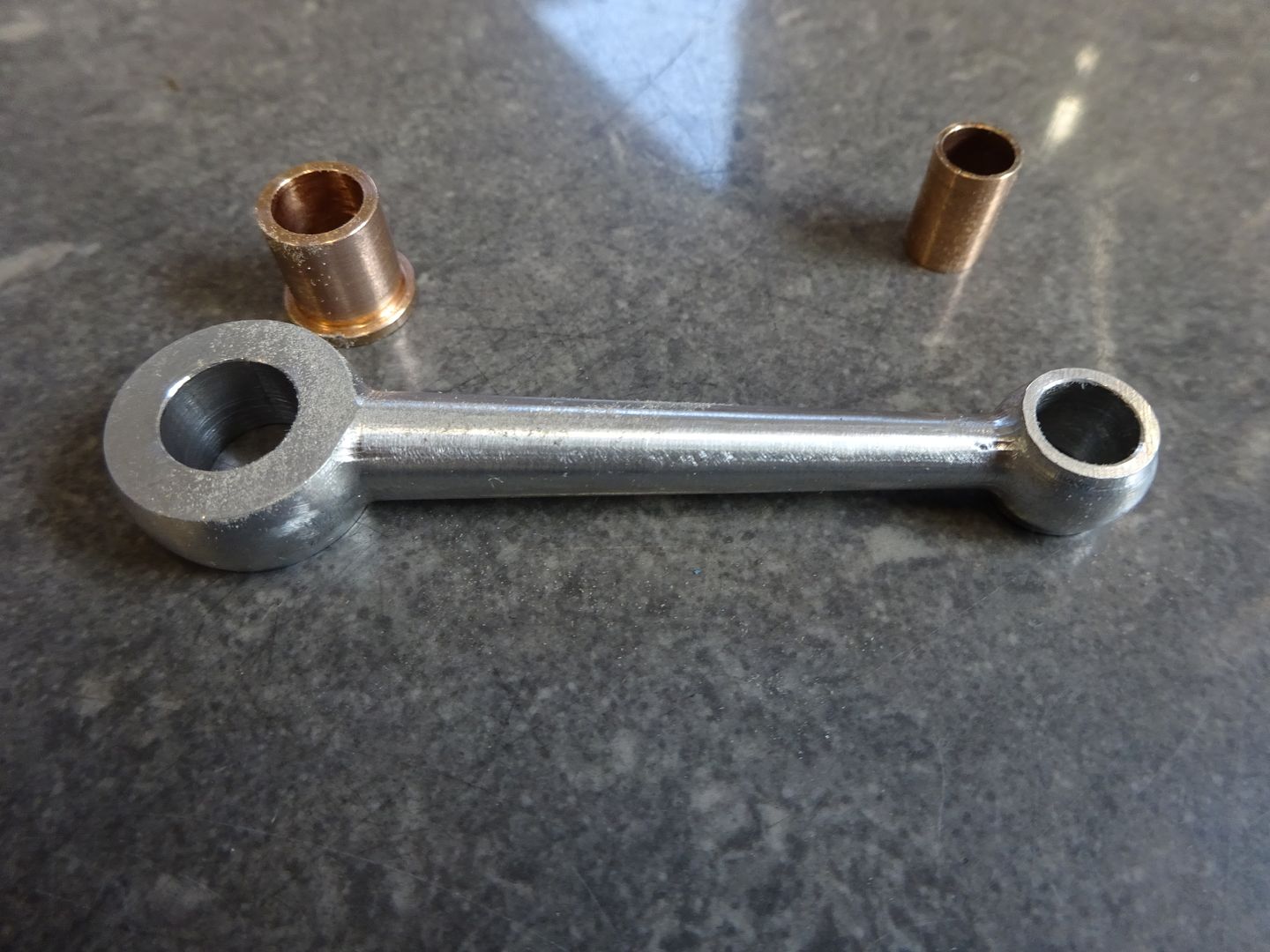

And after separating from the holding block. really happy with the finish which hardly needs any sanding, I set a small amount of backlash compensation to the Z=axis and that seems to have cured the marks I was getting in the previous parts cut using "steep and Shallow"

Video first showing the adaptive clearing (roughing out) and then the finish 3D cuts.

Sarah F.

![20200727_122720[1].jpg 20200727_122720[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/872026.jpg)