I had a bit of time this afternoon so thought I would do the top plate, I did not air cut this time but did practice on some PVC before cutting metal.

First was to drill 15No 2.5mm holes with a split point stub drill which meant I could get away without spot drilling first

Then a change to a 6mm stub drill to open up six of the holes

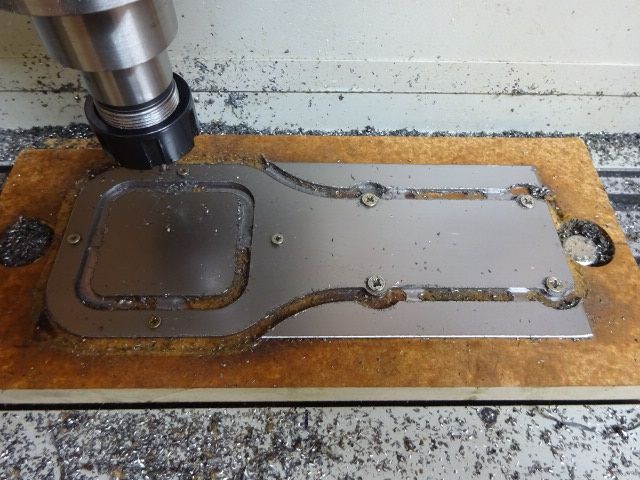

Using these holes the plate was screwed down to the MDF below and clamps removed. Using a 6mm dia 3-flute cutter but carbide this time the profile was cut, not a bad finish on the bottom of the first pass.

All complete, the 6mm piloted holes that open out to the edge were enlarged to 8mm as part of the contour cut and I left tabs again to stop the waste flying about.

After a clean up with the bottom plate that I cut at the weekend.

I've stitched two videos together here, the beginning shows the first pass with the cutter at full width but 1mm away from the finished edge, second half shows the final full depth finishing cut, you can see the tool rise and fall where the tabs are located. the Upload to Youtube seems to have added some high pitch noise which was not there at the time.

I could quite get to like this CNC lark, next part has been through the CAM and will let me try some adaptive clearing cuts!

Sarah F.