John,

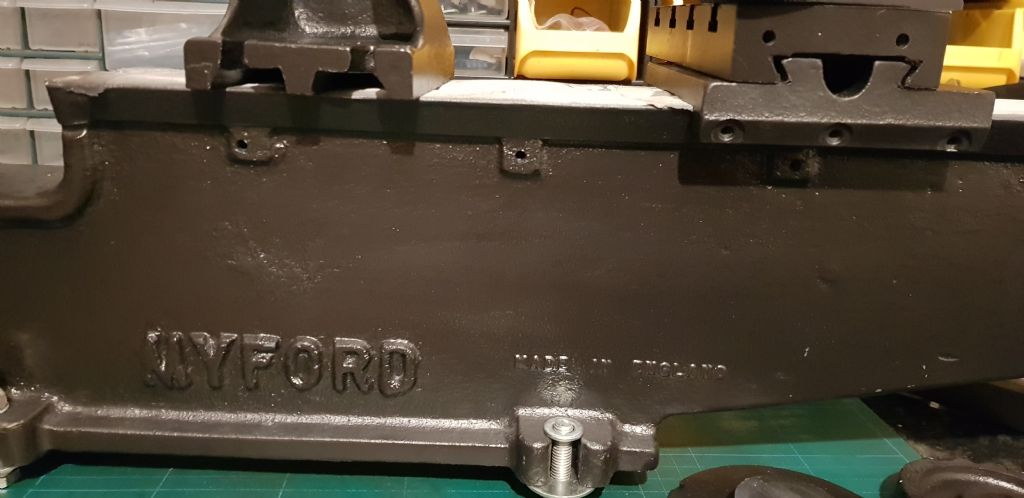

Study Tony Griffiths "Lathes UK" website, pages about the Myford ML1, 2,3 and 4.

It is a mine of useful information.

With a lathe of that vintage, all the threads should be Whit form. (i. e. The extra two tappings to clamp the swivel on the Topslide are 1/4 BSF. The Banjo is clamped with a 5/16 BSW setscrew. ) If the mandrel is 7/8" diameter, it will be either 9 tpi on earlier models, or 12 tpi on later ones.

Early models were flat belt drive, but later ones were V belt drive, or had been converted.

Early MLs were 3 1/8" Centre Height, but later ones were 3 1/2". I found that out the hard way; by assuming that the one I was going to help to return to service was 3 1/8". When I got to it, it was 3 1/2" and i had made a Centre Height Gauge for 3 1/8"! But the Mandrel was 7/8 x 9 tpi, so possibly a transition or field fix hybrid?

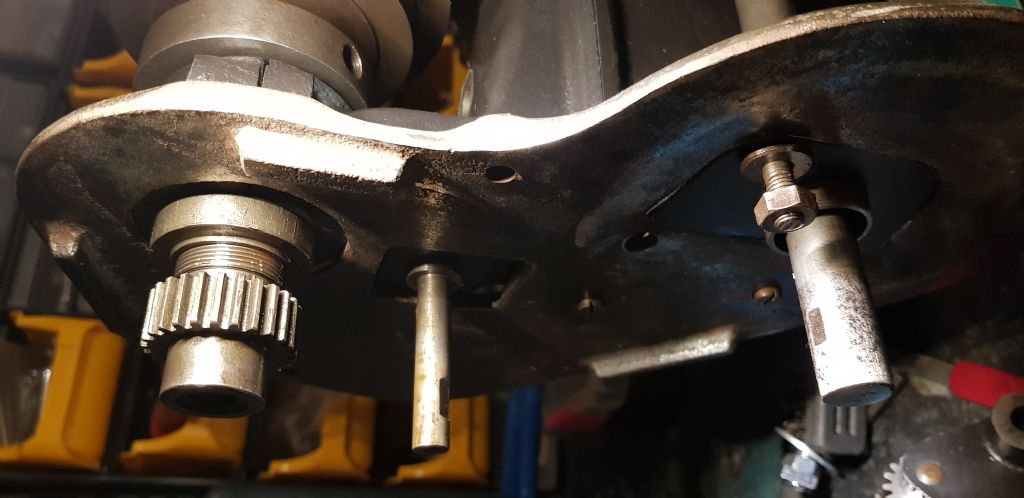

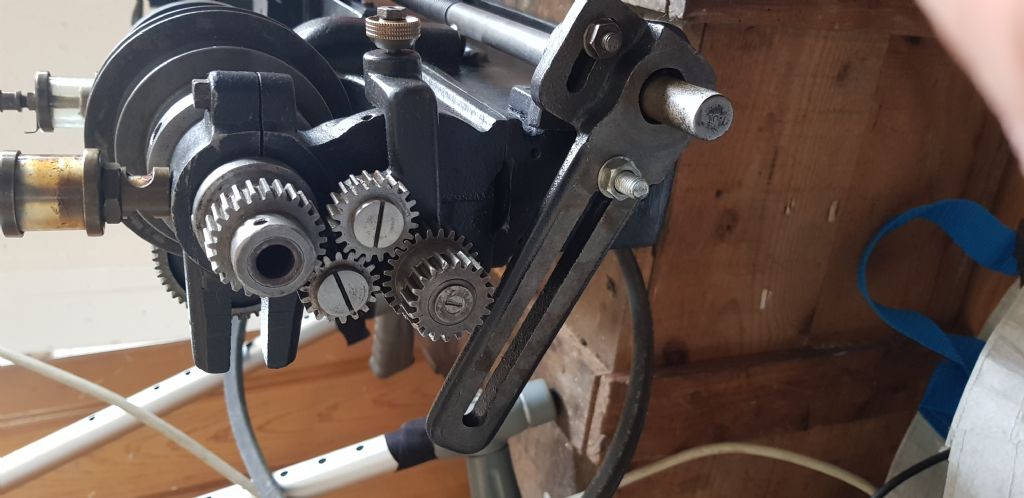

Not all machines had Tumbler Reverse; that was an optional extra, and ones without it do not have the tappings to fit it. Although, Tony Griffiths says that some owners have managed to fit the Tumbler Reverse from a ML7.

There are two tappings at the back of the Headstock. Those, I found out are for the cast bracket that carries the Changewheel Guard. Guards that hinge sideways are rare. Normally, they hinge upwards.

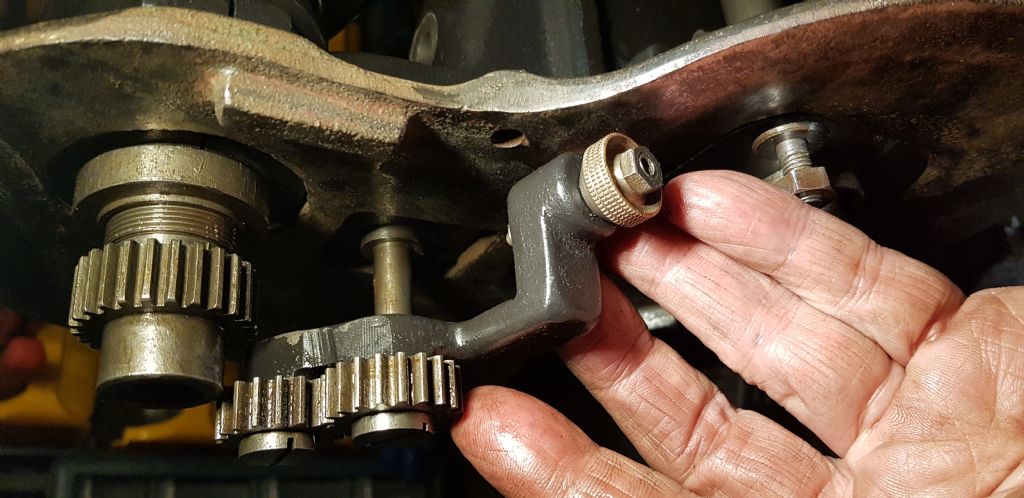

Changewheels are compounded by a 3/32" pin in a drilling which only goes part way through the gear. ML7 gears, with a keyway, can be used, by drilling a 3/32" hole for the pin.

Tony refers to some machines being factory painted in "Vomit Green"!

HTH

Howard

Edited By Howard Lewis on 07/04/2019 19:14:48

JohnM.

. My post on the first page of this thread gave details for identifying the different models.

. My post on the first page of this thread gave details for identifying the different models.