From Firth Came Forth… Compounding & Valve Gear?

From Firth Came Forth… Compounding & Valve Gear?

Home › Forums › Traction engines › From Firth Came Forth… Compounding & Valve Gear?

- This topic has 71 replies, 9 voices, and was last updated 2 June 2024 at 23:34 by

Nigel Graham 2.

-

AuthorPosts

-

1 May 2024 at 22:46 #728726

Nigel Graham 2

Participant@nigelgraham2Paul Kemp –

– gives me an accidental pointer, in his comments on Andy Stopford‘s Firth Valve Gear thread, re boiler pressure and compound working.

.

My 4″-scale but fairly small steam-wagon’s engine is compound (well, meant to be) but the original had no superheat and the steam-pipe from the boiler to the inlet was up in the open air and apparently un-lagged, so it can’t have been very efficient.

My thoughts with the miniature, in which faults tend not to scale, are turning to a 2-cyl simple with the prominent engine top disguised as compound by covers externally different in diameters. Its boiler is not very large, and has a w.p. of only 90psi (like Paul’s 2″ -scale Superba).

Although I had the boiler built, by Western Steam, with superheater flues to give the option, fitting a superheater would be difficult and give the steam a return trip of nearly three feet from regulator to smokebox and back to the engine. That excludes what would be four very small-bore elements, and probably introduces losses negating the benefits of the superheater!

.

The Firth discussion also tempts using a simple radial valve-gear (Hackworth or equivalent), although that does not readily lends itself to a side-by-side cylinder / valve-chest layout. Generally I would expect the engine to work in full-gear or nearly so, and forwards most of the time.

The original vehicle has vague hints of Stephenson’s Link Motion, but I do not know, as the works are all hidden behind “quickly detachable covers” – quoth the original Hindley catalogue. (My photo suggests lots of wing-nuts, but apertures above the covers give moderate access to the four glands.)

It is an enclosed, inverted-vertical engine mounted in the chassis behind the boiler, between the crew seats. In scale form, of 1.25 and 3″ bores X 2″ stroke compound, probably 1.5 to 1.75″ bores for a twin simple.

‘

Even these might not be true scale: the only dimensions I have were quoted in the manufacturer’s catalogue and a Commercial Motor magazine review of Hindley’s larger, under-type ‘Standard’ class wagons. When I first drew that one to scale, from the review photograph, the proportions were all wonky. It was a further three years before more information emerged, showing the text did not match the sample supposedly-‘Standard’ wagon illustrated!

…

Given I have to design (ish), re-design, make, re-make… this thing all the way through…..

Any thoughts on the above, please, chaps?

.

1 May 2024 at 23:07 #728730duncan webster 1

Participant@duncanwebster1If you really want to use a Hackworth type gear then consider the Woolf variant as described by Simon Bowditch in EIM in 2009. This has a rocker to reduce the height of the valve rod, can’t immediately see why it couldn’t be reduced to the same height as the cylinder centre line. You’d need to run it through Dockstader simulation program to save a lot of frustration.

I wouldn’t worry too much about exposed steam pipe, compared to the energy flow of hot steam along the pipe the heat loss should be quite small, and as shown by Mike Tilbey in ME recently, lagging small pipes can actually make things worse, the optimum thickness of lagging is quite thin.

Your cylinder sizes for compound are way off, that’s 5:1 volume ratio. Personally I’d stick with a superheaters twin simple expansion

1 May 2024 at 23:32 #728734Paul Kemp

Participant@paulkemp46892Nigel,

just a few off the cuff thoughts;

Compounding in miniatures, there are at least a couple of people who have done some investigations into this in recent years (Julia Old and Ross Bishop) the former on a 6” Burrell Gold Medal and the latter on a 4” Maclaran. I don’t remember the precise details but I think both concluded there was some benefit in their situations. Personally I am on the fence in my armchair having not done anything like the analysis that those I mention have! One simple experiment most obvious is power. The Fowler has a simpling valve which when actuated gives a noticiable increase in power – logical as you are admitting higher pressure steam directly onto the large LP piston. Obviously this is at the expense of steam, water and coal consumption. The valve, as fitted to various compound full size engines was really for use in starting and manoeuvring, although it is often claimed drivers did use them to get a bit of extra “oomph” in certain situations!

The other issue you mentioned in the other thread is valve travel – I think radial link motions of say Hackworth become inefficient as valve travel increases. So what kind of valve travel are you looking at?

I guess you also need to consider the layout and stroke of the engine, can you have the crank centreline a reasonable distance from the cylinders to fit the gear in, in good proportions?

I think you need to start at the end and work back to see what best suits your needs, by that I mean what performance / power are you looking for from the finished engine? Are you looking for something that will compete with a sentinel on speed and have plenty of pulling power or are you focussed on economy of steam, water and coal? Personally I would think you need a double high with a reasonably efficient valve gear and events, especially if you are looking for reasonable speed and power. I doubt compounding it at 90psi with potentially quite wet steam will give you a great benefit. If you can guarantee reasonably dry steam or even engineer a degree of superheat then you may be able to improve economy. Remember the compound will need appropriate volume of steam chest and transfer passage to get a good result.

Andrew and Duncan might want to comment…

Paul.

2 May 2024 at 07:08 #728752duncan webster 1

Participant@duncanwebster1If you can arrange a valve gear with sufficiently large port openings at short cut off, and avoid condensation, then compounding is just reducing mechanical efficiency by having another lot of gubbins whirling round. If you have enough superheat you avoid condensation, and models (well locos anyway) have low piston speed compared to full size, so port opening is less important.

Someone once did a paper which showed that the extra pressure drop caused by more tortuous ports in Midland compounds absorbed a lot of the advantage of compounding. It is significant that apart from France (and they always have to be different) compounds fell out of favour at the same time as superheating came in. Memory says the chaps name was Diamond, must do a search of the ILocoE archive someday

2 May 2024 at 11:46 #728786Nigel Graham 2

Participant@nigelgraham2Thankyou!

I don’t have a satisfactory drawing to be able to illustrate the practical difficulty of fitting a superheater, leading to inordinately long pipework.

I will try to produce one!

I am not too worried about fuel and water consumption – I am more worried if the thing will even have enough power to pull itself along, let alone with me sat on it!

.

The boiler is of locomotive form but with the outer firebox extended as much above the short barrel as below – like a pipeline T-piece – to give a high water-level. Hindley’s patent feature, to keep the tubes and crown-plate submerged even on 1-in-8 hills. (The factory was in a deep valley with a steep exit road, for a start.).

The engine is immediately behind the boiler, with the top of the cylinders approximately level with the flat top of the outer firebox – and in full-size a bit below the driver’s left shoulder.

The steam take-off is in that flat top-plate, with an elbow, an ordinary globe-valve as regulator then a short length of exposed pipe to the HP side of the engine, on that unit’s off-side end.

My photograph shows the rearward side of the HP valve-chest carries something operated by a tall vertical lever swinging across the vehicle. I take this to be a starting-valve, rather awkwardly placed in line with the back of the seat. Did the designer cater for steam-wagon with three arms?

.

So to fit the model with a non-prototypical superheater entails a pipe from the regulator descending the exterior of the firebox for about 9 inches to footplate level, running along the barrel for about 8″ to enter the smokebox through bulkhead-union in a broad annular ring, given by the box being an inch larger diameter than the boiler barrel. On its way back the steam emerges from the smokebox in a parallel pipe extending slightly astern of the firebox then rising to the engine inlet – without becoming entangled in the controls. Say about 20″ of pipe.

I’d envisaged hiding most of that three feet of plumbing under the cladding for appearance and to minimise heat loss.

Traction-engines and most overtype steam-wagons had direct ports from boiler to valve-chest, superheated or not; but there the steam is used almost at point of generation, in cylinders gaining some warmth from below.

This vehicle does not have that; but from your comments it would seem the short pipe from boiler to engine on the model would not lose too much heat, though might benefit either from thin lagging or by being polished.

Though apprently not original to the Hindley wagons a wrapping of cotton string would probably suffice, and look reasonably Edwardian. I know it must not be painted as that would lose the insulation effect, but it could sleeved with a sewn fabric tube.

…..

Regarding the valve-gear, since these simple radial gears are best suited to short valve-travels (lacking the combination-lever for the [lap+lead] component), I’d need proportion everything to suit. I would envisage a full-gear cut-off of 75%.

I’d originally envisaged 3/4″ valve-travels for that cut-off, guided by the proportions in Martin Evans’ book on model locomotive building. That was with Stephenson’s gear.

There is probably room in the engine case for the valve-gear itself to be all-square as these types should be, and there may be enough headroom between crankshaft and cylinders for a direct connection to the valve-spindle to be feasible without too much distortion of the valve events.

Also perhaps 0.01″ lead – an engine for a steam road-vehicle is intended to run fast, with a high gear ratio between crankshaft and axle. I doubt the full-size wagons managed more than about 6mph, especially on smooth-rimmed, all-steel wheels with no strakes or rubbers. I am designing for about 3 to 4mph (brisk walking pace), assuming the engine can copy the original 400rpm.

.

Hackworth, Marshall and Bremme in their basic forms are for the valve-chest above the cylinder (in front, if translated to my vertical engine). However that can be overcome where the piston-rods and valve-spindles are all in line above the crankshaft axis, by a lever whose own proportions can be set to reduce the necessary die-block obliquity, to a limited extent. (Too much would add extra load to the motion.)

.

Duncan –

I see – yes, use short travels and wide ports.

I’m puzzled by your “extra gubbins” comment though. There is the same amount of gubbins in a two-cylinder engine whether the engine is simple or compound, for any given valve-gear. The only “extras” for compounding are a starting-valve and generous receiver for the steam between cylinders: often just a large-diameter pipe.

Also, I’d scaled the cylinders directly from the originals, as quoted in the publicity material. They may have been for the ‘Standard’ versions of the wagons but that information is all that is available.

Since the stroke is the same for both cylinders it is the piston area ratio that matters, not swept volume though even using that as well would not change the overall ratio. Certainly according to my “full size” text-books, which I am using as much as those published for model-engineering.

So the ratios are about 2.6: 1 full-size and model. Not 5:1.

Whether that is theoretically ideal I would not like to say, but looking at my cylinder drawing it does appear proportionally similar to the many compound engines I have seen.

2 May 2024 at 12:17 #728790 JasonBModerator@jasonb

JasonBModerator@jasonbI’d be more inclined to say that lever is the regulator and not the globe valve before it.

Most traction engines don’t have ports (passages) straight from boiler to valve chest. The majority go to the regulator chest first and then on to the valve chest.

Heat is not just from sitting on top of a warm boiler, many make use of large passages or even jackets so the steam flows around the bore on it’s way to the regulator chest.

I think you have a typo in your bore sizes, should be 1.25 & 2″ bores not 1.25 and 3″

2 May 2024 at 15:01 #728807duncan webster 1

Participant@duncanwebster1See Jason’s ref to typo, if they both have the same stroke, the area ratio = the volume ratio. As you have presumably lower boiler pressure, there is no guarantee that the same ratio is appropriate. Might be of course, more research needed

Contrary to what intuition tells you, steam jacketing does not eliminate condensation, although I’m prepared to believe it helps. Read Bill Halls work from many years ago. As I’m on a coach on the way to Cornwall I can’t provide a reference, I’ll try to remember to do it next week when I get home.

- My reference to extra gubbins was related to locomotives, which tended to have 3 or 4 cylinders when 2 would have done, not relevant in your case

5 May 2024 at 17:52 #729318Nigel Graham 2

Participant@nigelgraham2Jason –

Thank you. Yes, 2” LP bore, not 3″ !

If that downstream valve is the regulator it is remarkably badly-placed for operating! Anyway, why would a steam-wagon of rather unsophisticated design need a steam stop-valve between the boiler and regulator?

The globe-valve’s hand-wheel is immediately accessible to the driver’s left hand, and in one or two surviving photographs showing a Hindley wagon with its driver on board, he is holding that wheel, not the other control. There is no sign of a starting-valve otherwise and the only possible reason for the arrangement is to allow refilling the displacement-lubricator between the two fittings – but still raises the question of why such a clumsy control layout.

There are no surviving originals, but there is a modern replica, Hindley steam-wagon that has made an appearance at the GDSF on at least one occasion. I am told by someone who claims to have driven it, that the regulator is indeed that globe-valve. I have not seen this vehicle, but I have met its builder, Richard ‘Turbo’ Vincent, at an early stage of the commissioned project, and he had the same problems as I have had in obtaining details on these extinct wagons.

(I did try to contact its owner but he seemed reluctant to let me visit him.)

…

Duncan –

A good point. I have not seen any formal material on the matter of relating ratio to pressure but obviously too low an inlet pressure could mean the steam is little better than wet fluff by the time the LP piston has reached mid-stroke. My reference-books for designing compound engines were all for large, full-size machines, typically for ships, in which 150psi boiler-pressure would be considered a minimum anyway.

Indeed, what advice I have seen suggests 90psi boiler pressure – before losses in the system – is too low for efficient compounding, certainly on a very small engine like this.

The system losses (radiated and conducted heat, throttling and wire-drawing through bends and valves, pipe and passage friction) are probably proportionately more significant in a miniature than full-size engine, and reciprocating steam-engines were never the most efficient machines anyway.

‘

I was not considering steam-jacketing anything. The nearest I’d contemplated was snuggling the superheater flow and return pipes up against the boiler, under the lagging, to reduce heat loss – and for appearance.

In practice the pipework losses would probably negate any advantage from the superheater, and I realised the four elements would not help because the flues are too small to allow return-bend types with sensibly-sized tube. They’d need be annular: not easy to make and still giving very restricted gas-flow areas past them.

…

In full-size, the cylinder ratios vary from engine to engine but there is a typical range, which I forget. The engines were designed to extract as much energy as possible from each dose of HP steam. This, if I understand my text-books correctly, was done by starting from the wanted Indicator Horse-Power as if generated in a single cylinder, and working back from that in order to share that power evenly between the cylinders.

.

(That point is lost by those who claim compounding is efficient because it “uses the same steam twice” – rather than using the same steam once without needing an inordinately long cylinder. Apparently that misunderstanding you sometimes hear repeated by rally commentators, was common even among professional traction-engine drivers in the vehicles’ commercial heyday.

Though to be fair most drivers were probably taught little more than driving and basic maintenance… which was often neglected. The Hindley advertising states “any man of ordinary intelligence can learn to drive” one of their wagons easily and rapidly – he was not expected to understand how it was designed! )

5 May 2024 at 18:55 #729325 JasonBModerator@jasonb

JasonBModerator@jasonbI just seems a very slow way to regulate the speed, just hope you don’t need to shut the steam off in a hurry! That is assuming it is standard valve inside as I suppose it could be 1/4 turn?

5 May 2024 at 20:26 #729332Anonymous

From my calculations steam flow in pipes in models tends to be laminar rather than turbulent. So although pressure drops might be larger, heat losses may well be smaller than expected. The characteristics of the pipe internals is an interesting question.When I was working in motor racing the engine manufacturer we worked with put a lot of effort into smoothing and polishing the inlet and outlet cavities in the cylinder heads. Sometime later it was discovered that a dimpled surface, like a golf ball, was more efficient.

It is correct to say that a compound with the same overall expansion ratio is no more efficient than a single with the same ratio. However, in a compound the temperature changes per cylinder will be lower, so less losses, and hence a slightly higher efficiency. Unlike many models in full size compounds the cylinders are fairly well isolated from each other which also helps. In thermodynamic terms the compound can get closer to ideal adiabatic expansion.

In full size it is usual to design such that each cylinder produces equal work. This means that the engine is balanced in the sense that each piston rod creates the same overall force.

Nigel: On your engine are the two cylinders in phase, or out of phase, and is there one set of valve gear, or two sets.

Andrew

5 May 2024 at 21:53 #729353Nigel Graham 2

Participant@nigelgraham2Jason –

My thoughts entirely.

The information on the originals is so sketchy – photocopies obtained over some years of old publicity material – that it is very hard to know exactly what did what and how.

Having bought a rather costly globe-valve with flanges for bolts, as correct (it is quite prominent), my thought is to use it but prepared to change it for a quarter-turn valve of similar external appearance. The original may indeed have been a plug-cock in a nearly-spherical body, but I have no way of knowing.

Really I need build enough of the vehicle to prove it will even work before worrying about fine details.

.

Andrew –

The pipework is all standard copper tubing, but of course the ports and passages in the cylinders will have whatever finish the machining leaves.

I know the principle of equal work – on some very large engines, especially vertical ones, the ports and valves were arranged to compensate for the space taken by the piston-rod and the weight of the moving parts.

I don’t know to what extent the thermodynamics of a full-size engine scale to miniature form, but I think the effect of losses worsen as the size diminishes. Smaller losses but larger in proportion. Given the number of small engines that work very well, it might not be something to lose too much sleep over; but the typical IMLEC results tables show even the winning miniature steam-locomotives are of remarkably low efficiency. If I follow Martin Evan’s book on locomotive building, for port and passage dimensions, I probably won’t go far wrong, although I am expecting this engine to revolve at higher speeds than a locomotive’s driving axles.

‘

The cylinders are at the conventional 90º arrangement to each other, so each having its own valve-gear.

‘

If I change its design to a twin-cylinder simple I would think each would need be 1.375″ or 1.5″ bore X 2″ stroke.

6 May 2024 at 09:53 #729383SillyOldDuffer

Moderator@sillyoldduffer…

Really I need build enough of the vehicle to prove it will even work before worrying about fine details.…

I don’t know to what extent the thermodynamics of a full-size engine scale to miniature form, but I think the effect of losses worsen as the size diminishes. Smaller losses but larger in proportion. Given the number of small engines that work very well, it might not be something to lose too much sleep over; but the typical IMLEC results tables show even the winning miniature steam-locomotives are of remarkably low efficiency.…

Far better if you can to sort out as many small details as possible before building anything! Problems solved on paper, CAD, or with cardboard are dirt cheap in time, money and materials compared with bashing metal. Fixing design issues by actually making prototypes can be good fun, but it’s the slowest possible way of making progress. So slow, the project might never finish.

How thermodynamics scale when building model steam is well-known, and the law is very bad news for efficiency. I’d go so far as to predict compounding a small engine will always make it less efficient, never better. Trouble is the second cylinder adds friction and parts that absorb energy when they move. Steam waste from the first cylinder has to contain enough heat to move the compound at all, and only after that is their any hope of an efficiency gain.

In practice, compounding full-size railway locomotives didn’t work out well. Although thermal efficiency was improved slightly, the extra weight and complexity made it more economic to run engines without compounding them. Been done on traction engines though, usually with an arrangement that allows compounding to be turned off, or fed full-pressure steam as a power booster rather than economiser. Marine and mill engines are a different story; they have the space for a hefty condenser, layouts allowing short pipe runs, and plenty of insulation.

In a model, compounding is more about looking correct, don’t expect efficiency as well.

The formula that torpedoes small heat engine efficiency is the ratio between volume and surface area. Surface area follows a square law, whilst Volume follows a cube law. Small boilers contain a low volume of heat, with a relatively large surface area radiating it away. Conversely, a big boiler contains proportionally much more heat, and stores it better because it also has a relatively smaller surface area. The law applies to almost all the parts in a steam loco, so a small engine is pretty much entirely built of components that waste heat disproportionally, and most of it is gone before reaching the compound.

Same square/cube law losses apply to superheat. Not difficult to superheat steam inside the spear, but every inch the steam travels towards the valve gear loses temperature hand over fist. I think most model superheated locomotives are marginal: only the best deliver a useful quantity of dry steam to the piston, whilst the worst cool it below boiler temperature.

I believe the Newcomen Engine is the most difficult to miniaturise because they waste so much heat even in full size! What’s the smallest Newcomen engine anyone has got to run?

Dave

6 May 2024 at 12:35 #729406Nigel Graham 2

Participant@nigelgraham2Thankyou!

I did try to design the wagon on paper – and later by CAD, but found that too difficult for much more than simple, individual parts. I bought CAD very much for this wagon project but it proved far more obstacle than help, discouraging rather than encouraging. (CNC machining and 3D printing are definitely out of the question.)

I’ve not tried the other version of CAD: Cardboard Aided Design. If I salvage enough of my dismantled drawing-board I can use that (with revision from old text-books) to make for example, paper patterns for the boiler cladding sheets.

Unfortunately I had to start building the thing, to gain any idea how to design the next steps; and very often even parts made from drawings later prove wrong. So now it has to be designed and made in small steps, trying to foresee future problems with areas not yet designed or resulting from components made years previously.

.

I think most steam-wagons, even those of better designs than Hindleys’, had no superheater. Garrett fitted superheaters on some of their overtypes, but otherwise superheating was mainly for the later, much more sophisticated ‘Sentinel’, Foden, etc. undertype lorries.

The Hindley ‘Standard’ wagon was an undertype with direct gearing so the engine was quite a long way from the boiler, but even that seemed to use wet steam. The exhaust must have really struggled to reach the chimney top!

.

The Newcomen Engine and its semi-portable form developed by John Smeaton (to allow dismantling when a mine closed, for re-assembling at a new one) have been built in miniature, fully-working form; by Ron Jarvis. His genre – early, especially unusual or pioneering steam-engines – and workmanship paralleled those of Cherry Hill, and I believe they knew each other as friends and fellow-competitors at the major exhibitions’ top award-winning levels.

To be fair, Ron had to use 20th Century engineering to help his Newcomen Atmospheric-Engine, standing nearly two feet tall, work. Its boiler is only about the size of an orange, complete with orange-peel planishing for the hand-forged effect, working at only about 2psi. So it holds an electric heating element controlled by a microprocessor concealed in the plinth. Ron would joke about this Computer-Controlled Eighteenth-Century engine!

Otherwise it all, correct lead piping and all, operates as its prototype.

I never had the pleasure of seeing it operating, but Ron made at least some of his engines to be operable; though some such as his paddle-steamer engine were more likely powered by compressed-air. It is hard to see how his replica of Dr. Church’s steam omnibus could possibly run under steam, except perhaps with a CNC Boiler and on a rolling-road. (The original, intended as a long-distance coach, was a bizarre vehicle; totally over-specified, over-complicated, over-decorated, over-heavy and under-powered.)

.

Ron, a long-time Weymouth & District M.E.S. member, photographed and described all his models and the history of their prototypes in a glossy paperback, Art And Old Iron.

Unfortunately, privately published under the name “Beverley Books” of Southwell, Portland (where he lived), it had only one, fairly modest print-run and you’d probably struggle to find a copy now. I don’t know if TEE Publishing have any copies, but they might appear second-hand from time to time.

I do not know where Ron’s engines went. I think he had bequeathed them to a suitable museum – hopefully one run by people who understand what they curate.

6 May 2024 at 13:20 #729415duncan webster 1

Participant@duncanwebster1Several people have measured steam temperature at the cylinder. Plenty of evidence that superheat gets there. It is difficult to imagine how ‘the worst cool it to below boiler temperature’. On a loco the superheaters and following pipework are either in a flue surrounded by combustion gas which is above boiler temperature and enclosed in a flue which is at boiler temp, or in a smoke box, again surrounded by gas at above boiler temp. Only a short length is in the outside world, and the energy flux along the pipe is a lot more than the heat loss from this small area, so it won’t cool down much.

Superheat works in full size, it works even better as size gets smaller. Mill engines are a different argument, with a condenser you get a much bigger volumetric expansion ratio, so I suspect you’re forced down the compound route, although prof Stumpf disagrees. Mill engines didn’t go in for high superheat. I’m not sure why, possibly by the time superheat came in (early 1900s) the age of big mill engine building was passing, possibly because a saturated engine will probably survive a lubricator packing up, superheat won’t, and if your engine packs up you shut the mill for weeks.

6 May 2024 at 13:22 #729417duncan webster 1

Participant@duncanwebster1At least 2 experimenters have measure model loco boiler efficiency, come out at ~70%,similar to full size loco.

6 May 2024 at 13:56 #729419 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133Ron, a long-time Weymouth & District M.E.S. member, photographed and described all his models and the history of their prototypes in a glossy paperback, Art And Old Iron.

Unfortunately, privately published under the name “Beverley Books” of Southwell, Portland (where he lived), it had only one, fairly modest print-run and you’d probably struggle to find a copy now. I don’t know if TEE Publishing have any copies, but they might appear second-hand from time to time.

Here’s an opportunity for someone !!

https://www.amazon.co.uk/Art-Old-Iron-Dimensional-Industrial/dp/0954068807

MichaelG.

6 May 2024 at 17:31 #729435Nigel Graham 2

Participant@nigelgraham2Duncan –

70% efficiency?

Of the boiler alone, perhaps, though that seems very high.

The overall efficiency of the system is what counts in practice, and the one that I worry about. Normally you can divide that value by at least 10 for this.

Even the best full-size steam-locomotives never managed much better for the overall system – i.e. potential heat energy of the coal to kinetic drawbar energy.

By comparison the overall efficiency of a coal-fired power-station, with all its sophisticated control, mechanised firing, economiser, feed-water heater, etc., is <40%.

…

I agree with your points regarding the superheater on a locomotive but they would not apply on my application. It poses two practical problems:

– making superheater elements fit, and work in, quite small flues (hence considering annular elements),

– installing headers in a rather cramped smoke-box with very limited space behind the petticoat pipe and above the highest fire-tubes in a nest that with the flues, occupies most of the barrel diameter*;

– and the functional problem of inordinately long external pipes from regulator to superheater thence back to the engine (aft of the boiler).

Essentially I was considering how to put a superheater on a miniature replica of a vehicle that never had one in full-size, and although the boiler has four flues for it, I do not now think it feasible practically or worthwhile thermodynamically.

.

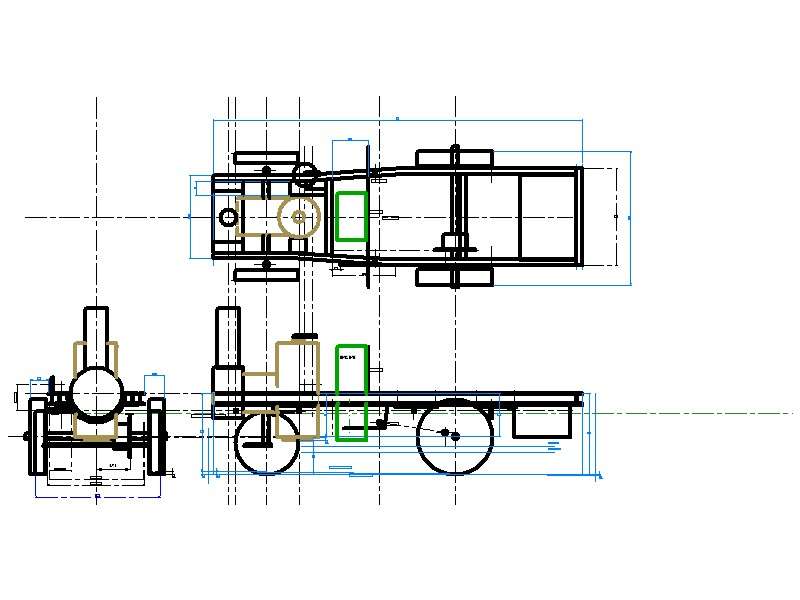

I will try to produce a basic GA of the front of the wagon to show what’s where. I have a very rough, partial orthographic drawing in TurboCAD and might be able to do something from that. Attached below. I have not tried to create a 3D image: I cannot possibly do that in either Alibre or TurboCAD; but the latter allows orthographic drawings.

The green rectangle represents the overall outline of the engine including the cylinders. The boiler is in brown outline. The steam outlet and regulator valve is not shown but is at about two-o’clock in plan on the circular firebox top (the middle circle is the ‘stoking-shoot’ to use the original makers’ term). The engine’s steam inlet is on the rear off-side corner of the engine top – the cylinder block is itself rectangular.

So a superheater would need a pipe drop from the regulator to slightly above chassis top, forwards into the smokebox through the latter’s wide internal flange; return beyond the boiler then back upstairs to the engine inlet.

Sorry- you may need enlarge the screen to view the picture!

.

””’

Oh – strange! The left-hand Shift key works On All Letters Except ‘T’. I needed use the right-hand key to start “TurboCAD” but the left one still works for the “CAD” bit. This has only just developed. Have I mistyped some arcane control combination?

@@@@@

* Unlike a conventional locomotive-type boiler the working water-level is above the entire barrel, by about two inches minimum on the model version. There are probably more fire-tubes than in the original, too! The number and size were calculated by Western Steam, its builders.

6 May 2024 at 18:55 #729455

6 May 2024 at 18:55 #729455 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133Picture is currently AWOL, Nigel

… perhaps it will appear in the fullness of time.

MichaelG.

6 May 2024 at 20:24 #729470Nigel Graham 2

Participant@nigelgraham2Strange – it’s on here! I did ensure I’d saved the image, directly copied from the original drawing, in jpg form.

6 May 2024 at 21:45 #729473 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133 6 May 2024 at 21:57 #729479

6 May 2024 at 21:57 #729479Nigel Graham 2

Participant@nigelgraham2I’ll try and re-copy it….

Somewhat simplified and tidied. Bunkers, footplates, seats, springs, most steering and transmission components and most smaller details omitted.

7 May 2024 at 13:54 #729535

7 May 2024 at 13:54 #729535Martin Johnson 1

Participant@martinjohnson1I am new to this thread so may not have grasped the full implications, but Nigel queried whether:

A duplex (twin high pressure) cylinder layout as opposed to compound would be a better choice. – Duplex works well on smaller scale Foden lorries and with the limited pressure of a copper boiler would be my preferred choice. I run a compound 4″ traction engine which will still run compound down to about 100 psi, but if you have a smallish scale model and want to live in the hurly burly of a rally field, you need flexibility and reliability. Go twin high, unless you are really wedded to fidelity to prototype.

Whether one of the Hackworth variants would be a good choice of valve gear. – I have built a large scale steam lorry with Woolf valve (as seen in Simon Bowditch’s articles). It is an excellent gear and the reversing link in the valve link does a lot more than just reverse the motion. It cancels out a lot of errors inherent in Hackworth and by carefully designing the angles of the reversing link, you can improve equality of events to a very good degree.

Whether the friction losses in the extra pipe length associated with superheating would negate the benefit of superheat. – I have written a spreadsheet (ably assisted by Duncan Webster and others) which will predict performance of a locomotive type boiler with (or without) superheaters. Over the 10 years or so that I have been using the spreadsheet on a variety of projects, I have only come across one case where friction losses are an issue – Doug Hewsons B1 design using 5/32″ tube. In most model designs, the friction losses amount to a fraction of 1 psi! The benefits of superheating are not that well undersood by model engineers, but in short it suppresses condensation losses (sometimes known as missing quantity) in an engine. Bill Hall MEASURED a reduction in steam consumption of 50% or so comparing saturated and modest superheat on the same engine. The results and report can be found on the ASTT website. Therefore, I would strongly recommend superheating.

Susbsequent to the OP there has been some discussion of what flow regime pertains in model steam engines. I greatly admire Andrew Johnston’s engineering, but have to differ with him about flow regime. Within model steam pipes, you typically have turbulent flow (Reynolds number in the order of several thousand). With boiler tubes and flues (combustion gas) you typically have laminar flow (Reynolds in the hundreds) but that rather depends on scale. Somewhere about 7 1/4″ gauge, combustion gas flow turns turbulent. All that depends on the particular design and how hard it is worked of course.

I also note a model boiler efficiency in the order of 70% is quoted. Test results on a LBSC Brittania boiler show that is not a crazy figure to aspire to. However, with the condensation issue potentially doubling the steam demand, superheat is a really important variable to think about.

My boiler analysis program is there for the asking, just pm me. I am happy to assist with putting in the data and understanding what it throws out.

Have we discussed this build in the context of steering geometry in a previous thread?

Martin

7 May 2024 at 22:57 #729587Nigel Graham 2

Participant@nigelgraham2Thankyou Martin.

I have started revising the cylinder design, bearing in mind the block has to be munched out of solid cast-iron bar.

Also the top covers need resemble those for a compound engine, and this makes sizing and placing the outlines and PCDs of the stud holes tricky!

.

My concern about the superheater, apart from whether there is even room in the smoke-box for the headers, is that this installation is nothing like that of a railway locomotive.

On a locomotive there is a short pipe from the regulator to the superheater, then short ones from that to the valve-chests. Even a backhead regulator as used on some narrow-gauge outline models gives a comparatively short, direct tube forwards, usually inside the boiler so not losing any heat, to the wet header.

The wagon would need about 18 inches of 3/8″ tube from the regulator to the smoke-box entry, then something like 2 feet from the smoke-box back to the “HP” valve-chest, on the off-side end of the transversely-mounted engine.

.

I have no idea how efficient this boiler will be. It is of an unusual design, not very large, and it will not be easy to fire as the 4.75″ diameter grate is nearly 15″ below the top of the 2″ diameter, 7″ deep vertical “stoking shoot” – as the original manufacturers called it. On the other hand there is a considerable area of inner firebox surface above the fire, and though short the barrel is nearly full of fire-tubes since the steam space is well above it.

.

Yes – you have encountered this wagon previously. I had asked for some guidance on typical number of turns from lock-to-lock of the steering-wheel on a steam-wagon.

So far it still carries a rather flimsy but temporary worm-and-wheel, enough to move the very unfinished thing about.

E.S. Hindley & Sons’ factory was in North Dorset, but they also had a sales office in London, facilitating trade reviews. Among the assorted bits of archive material that form my only information on these wagons, is one such in which the journalists praised the ease of handling determined by running their sample Hindley ‘Standard’ round and round Finsbury Circus several times!

8 May 2024 at 07:57 #729601 JasonBModerator@jasonb

JasonBModerator@jasonbWhy cant you pick up the wet steam supply from the top of the vertical part of the boiler and run a stainless tube through one of the boiler tubes ( did you say there was provision for this) to your superheater in the smokebox and then back. This will keep it all hot as the flue gasses pass over the pipes and then bring it out the top of the boiler to your regulator.

The wagon would need about 18 inches of 3/8″ tube from the regulator to the smoke-box entry, then something like 2 feet from the smoke-box back to the “HP” valve-chest, on the off-side end of the transversely-mounted engine.

8 May 2024 at 09:50 #729624Nigel Graham 2

Participant@nigelgraham2Your suggestion would certainly work but only if built in from new. The boiler has been made – rather a long time ago – and can’t be modified.

It would have be impossible now. Firstly the boiler has no provision for it and it could not be modified to suit. Secondly, assembling the superheater and fitting it to its connections would require manipulating screwed joints near the roof of a firebox less than five inches internal diameter and about a foot high.

I think I did consider something along the lines you say, but realised it would be impossible unless the boiler is built as the full-size ones were. Those had the main parts of the shell and firebox bolted to each other with big flanges, as some other makes of vehicle and small plant boilers were made. Even then it would be very difficult, though a radiant form entirely in the firebox would be easier.

Hence fitting a superheater to something not really designed for one needs long runs of external pipework. I’m not sure there is even room within the smoke-box, because the flues are close to the top of the barrel and there is very little room for the headers and connections.

.

I’ve just had to remind myself of my original question! It was actually about the engine: compound or simple, and what valve-gear.

This thread is showing I need discard the compound cylinders I made years ago, and make a new twin simple block, as the boiler pressure is only 90psi and fitting a superheater is mechanically difficult and possibly not be very effective anyway. The advantages claimed are right for railway locomotives, but this wagon cannot be compared with a railway locomotive. Its boiler design is only slightly similar, and the vehicle layout is totally different.

I have made the crankshaft, and as it is for Stephenson’s Link Motion it can easily be fitted with single-eccentric valve-gears (Hackworth or Marshall). That would even allow slightly wider eccentrics and main bearings.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Traction engines › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Boiler Design – issue 4765

1

2

…

7

8

Started by:

Charles Lamont in: Model Engineer & Workshop

- 26

- 199

-

14 July 2025 at 07:23

JasonB

JasonB

-

Screw cutting 1.25mm pitch on a Colchester Student.

Started by:

Kevin Nicholls in: Manual machine tools

- 2

- 2

-

14 July 2025 at 07:17

sprocket 3

-

TurboCAD – Alibre File Transfers.

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 5

- 19

-

14 July 2025 at 07:04

JasonB

JasonB

-

Indicators – vehicle

Started by:

Speedy Builder5 in: Electronics in the Workshop

- 4

- 6

-

14 July 2025 at 06:02

Speedy Builder5

-

buying machine tools from aliexpress experiences?

Started by:

Jake Middleton-Metcalfe in: Manual machine tools

- 16

- 20

-

14 July 2025 at 02:13

Neil Lickfold

-

Sat nag

1

2

Started by:

duncan webster 1 in: The Tea Room

- 18

- 37

-

14 July 2025 at 00:03

Nigel Graham 2

-

Variable DC power supply?

Started by:

Andrew Tinsley in: Electronics in the Workshop

- 4

- 7

-

13 July 2025 at 22:06

Andrew Tinsley

-

Silver steel crankshaft

Started by:

teamricky in: Stationary engines

- 7

- 15

-

13 July 2025 at 18:27

teamricky

-

Another Day … Another ScumBag

1

2

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 15

- 33

-

13 July 2025 at 17:42

Nigel Graham 2

-

Adjustable spanner thread direction

Started by:

jimmy b

in: Workshop Tools and Tooling

jimmy b

in: Workshop Tools and Tooling

- 9

- 9

-

13 July 2025 at 15:45

Martin Kyte

-

Electroplating questions

Started by:

Baldric in: Help and Assistance! (Offered or Wanted)

- 3

- 3

-

13 July 2025 at 13:42

noel shelley

-

“swedish iron”

Started by:

moonman in: Materials

- 11

- 15

-

13 July 2025 at 09:47

Martin Kyte

-

Difficulty in sourceing 2.5mm s/s ‘Full’ nuts

Started by:

Greensands in: General Questions

- 7

- 12

-

13 July 2025 at 09:22

Roger Woollett

-

Rotary valve engine

Started by:

AStroud in: Stationary engines

- 2

- 3

-

13 July 2025 at 08:49

AStroud

-

Sanjay’s Banjo Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 3

- 12

-

13 July 2025 at 06:50

Diogenes

-

I’m Under Pressure

1

2

Started by:

howardb in: Related Hobbies including Vehicle Restoration

- 17

- 31

-

12 July 2025 at 22:00

Howard Lewis

-

Help for DIY lathe build.

1

2

Started by:

moogie in: Help and Assistance! (Offered or Wanted)

- 16

- 36

-

12 July 2025 at 21:42

Howard Lewis

-

Electronic leadscrew pitching error

Started by:

paulg 1 in: Introduce Yourself – New members start here!

- 2

- 6

-

12 July 2025 at 21:08

paulg 1

-

New Member From The Isle of Man

Started by:

sprocket 3 in: Introduce Yourself – New members start here!

- 4

- 4

-

12 July 2025 at 20:57

Howard Lewis

-

Farm Boy

1

2

…

4

5

Started by:

Dalboy in: I/C Engines

- 15

- 103

-

12 July 2025 at 18:51

Dalboy

-

The Silver Swan Automaton

Started by:

James A in: Related Hobbies including Vehicle Restoration

- 3

- 5

-

12 July 2025 at 18:46

James A

-

Model Turbines

1

2

…

24

25

Started by:

Turbine Guy in: Stationary engines

- 28

- 607

-

12 July 2025 at 16:28

Turbine Guy

-

Nozzle dot dwg

Started by:

Michael Gilligan

in: CAD – Technical drawing & design

Michael Gilligan

in: CAD – Technical drawing & design

- 1

- 1

-

12 July 2025 at 14:47

Michael Gilligan

Michael Gilligan

-

Yet another scam

Started by:

Dell

in: The Tea Room

Dell

in: The Tea Room

- 2

- 2

-

12 July 2025 at 10:16

Bo’sun

-

Chester Champion, warco ZX15 drawbar

Started by:

martian in: Manual machine tools

- 5

- 7

-

11 July 2025 at 21:51

Howard Lewis

-

Boiler Design – issue 4765

1

2

…

7

8

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Boiler Design – issue 4765

- Screw cutting 1.25mm pitch on a Colchester Student.

- TurboCAD – Alibre File Transfers.

- Indicators – vehicle

- buying machine tools from aliexpress experiences?

- Sat nag

- Variable DC power supply?

- Silver steel crankshaft

- Another Day … Another ScumBag

- Adjustable spanner thread direction