Hello all,

I want to update some findings.

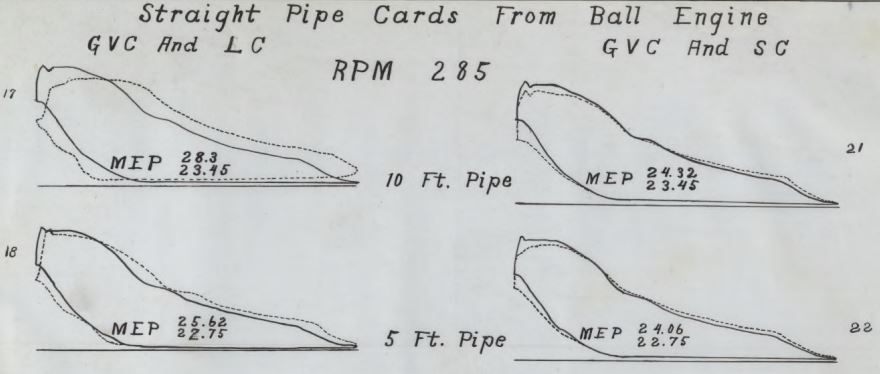

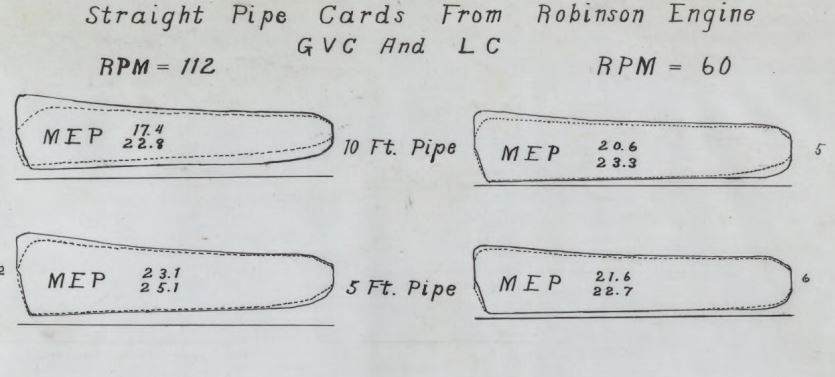

I looked in the theortical steam diagrams and so I had some doubts about my measurements.

I double check the electronic and all was correct. The doubt came up ,because the pressure at the beginning have to be high and then a steady phase and then To the end lower pressure.

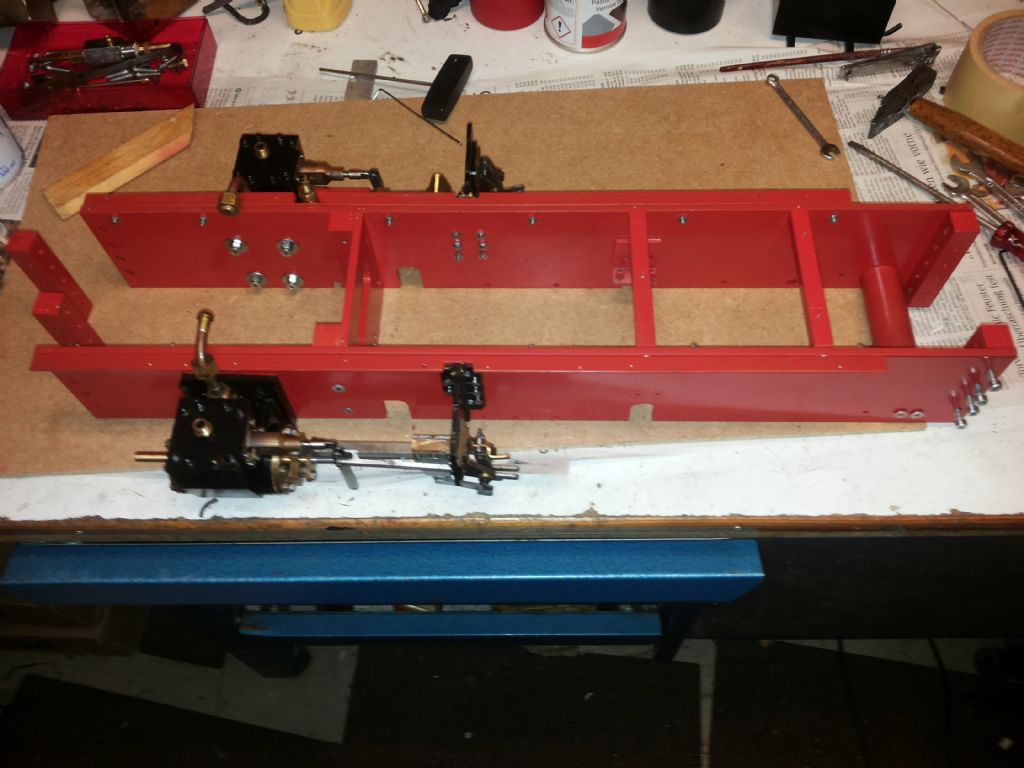

In my measurements it is more in the opposit direction. So I asked me where this come from. The only involved part is the exentric. I measured the excentric and compared it to the 3,5 inch Gezina drawing. I saw there is an error in the dimension. It have to be 19.5 mm and it was 18 mm. I looked more into the system and had the opinion that 21 mm are correct. So I made new excentrics with 21 mm.

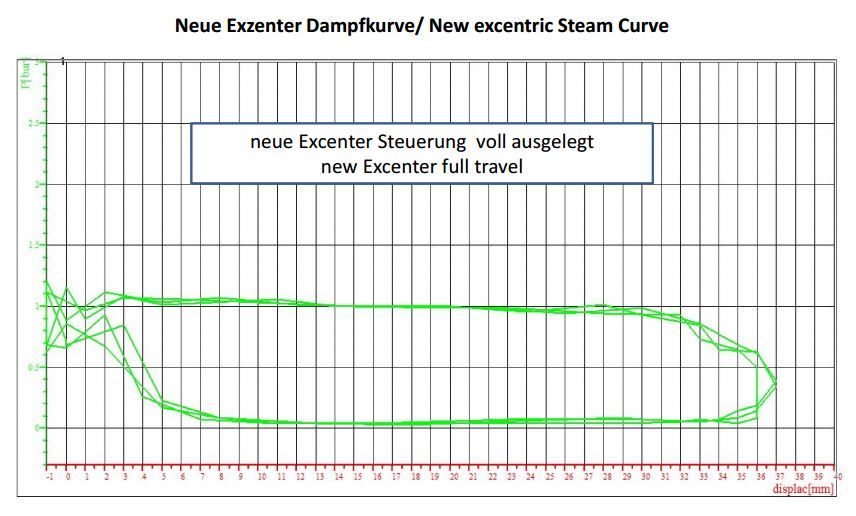

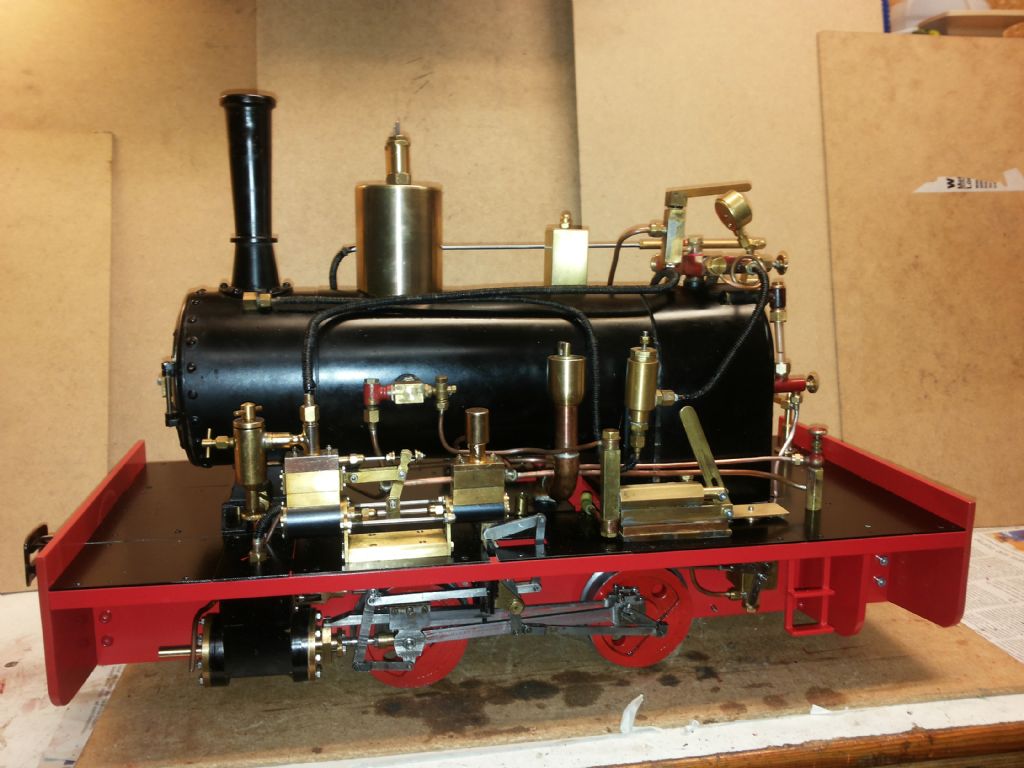

Than I test the loco with pressured air. In the first step the steam engine runs in forward direction much smoother than before . Backwards it was not so good but better as before.

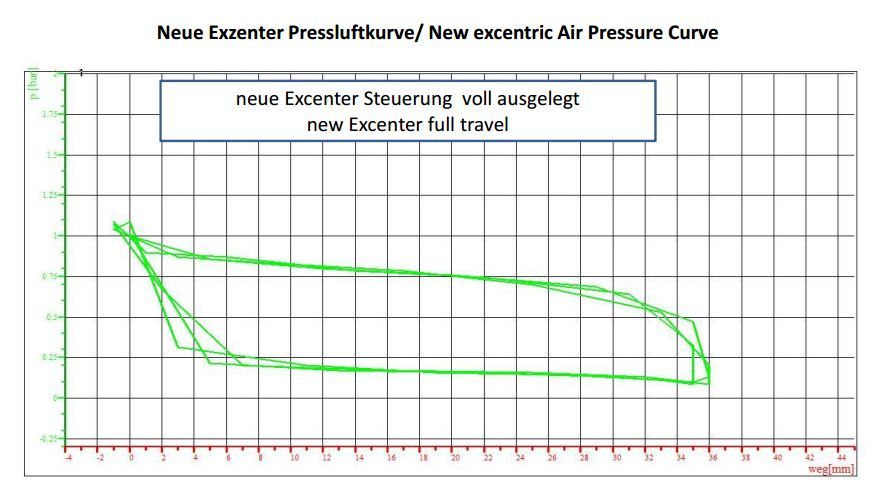

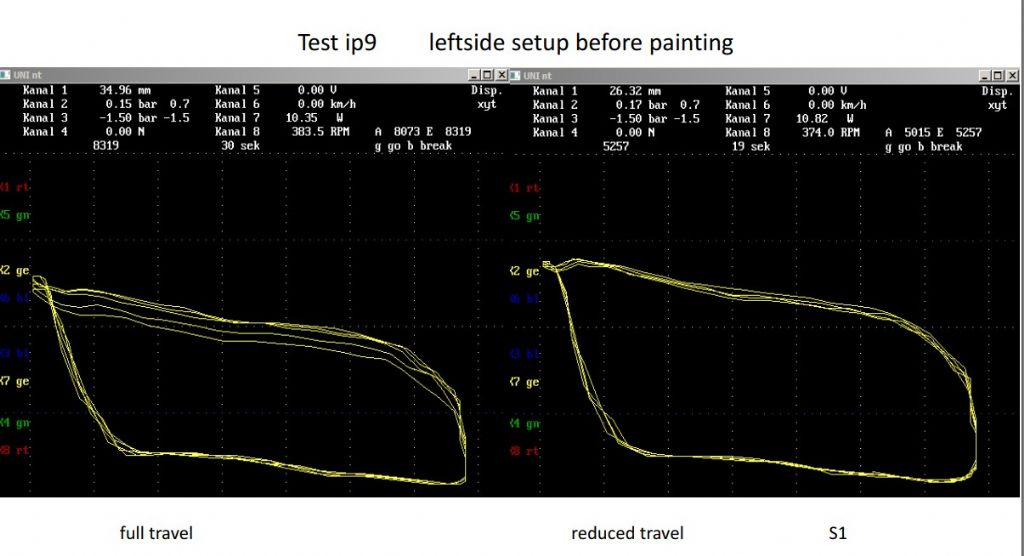

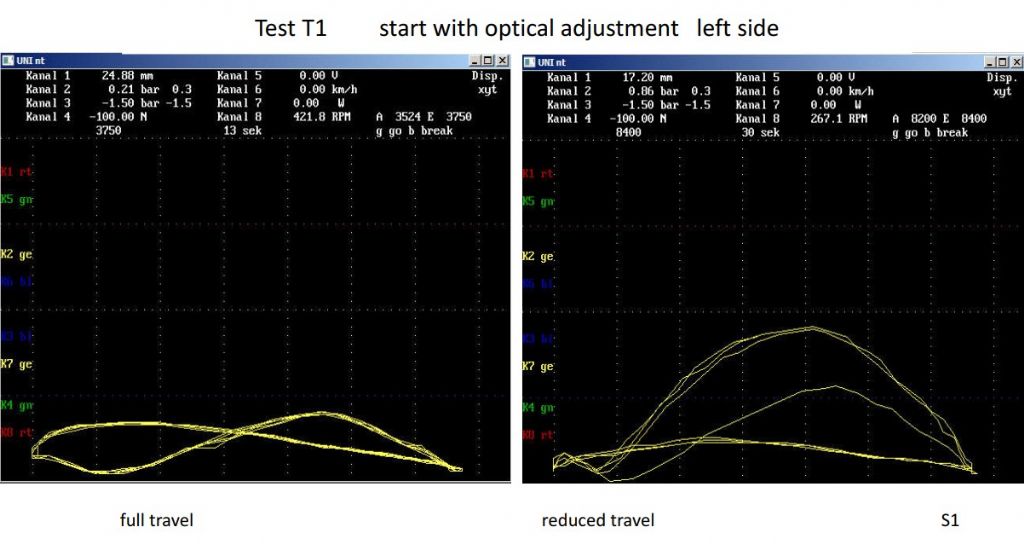

I decided then to measure with pressured air to see how it changes.

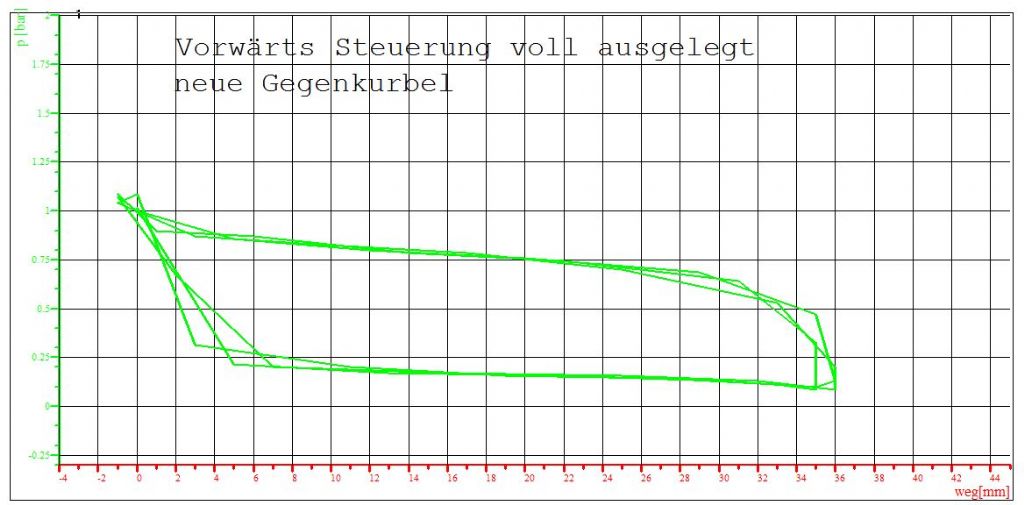

this looks now more as a "Zeunert" Diagram . The pressure comes from the beginning some steady phase and a pressure drop to the end.

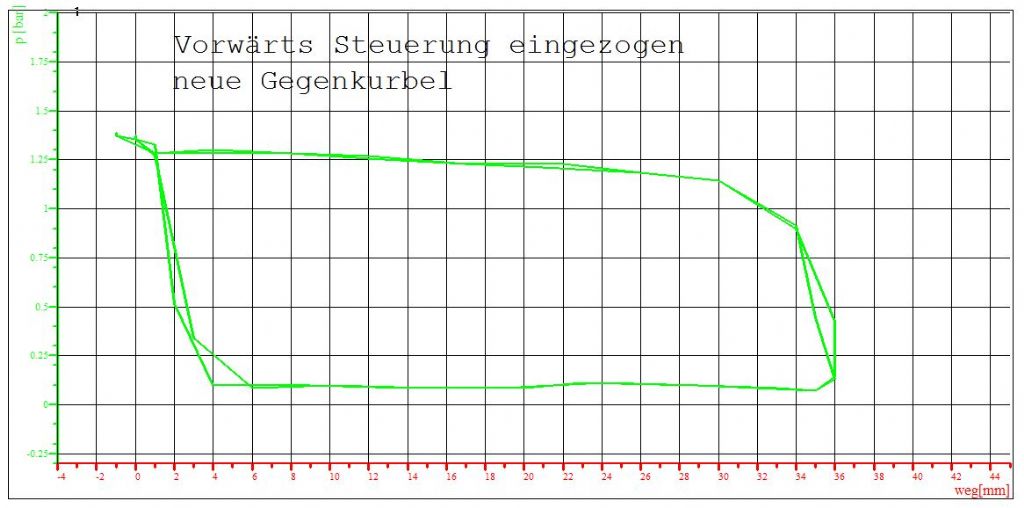

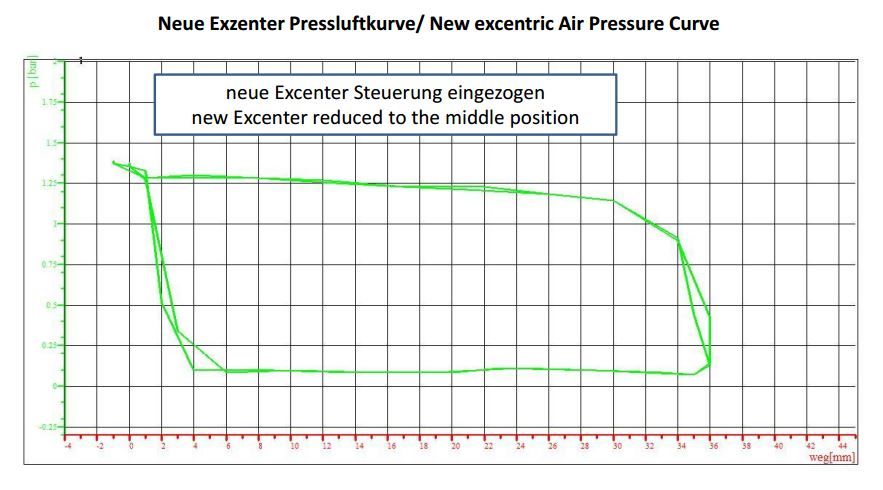

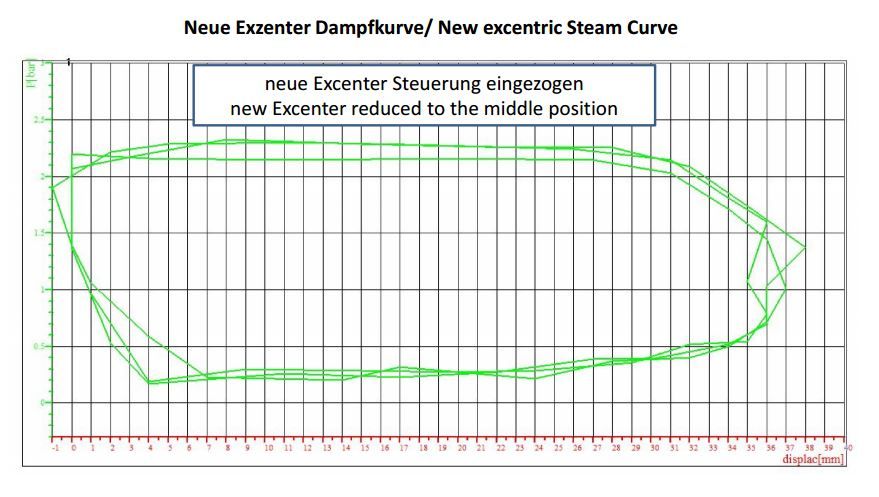

The steam engine runs smooth under this condition. With the reverse lever one step to the middle position it looks like the following picture.

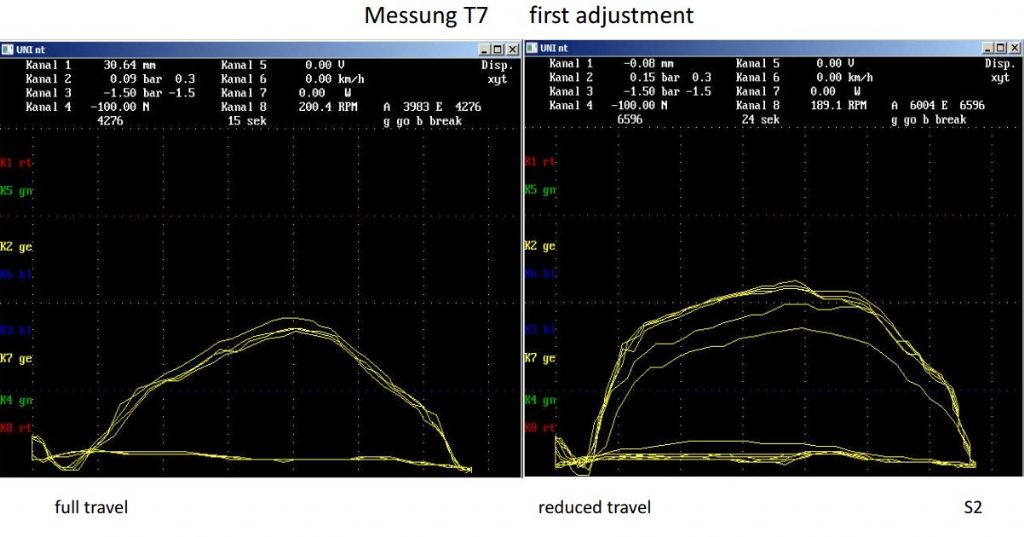

The engine runs faster with less air usage, so the pressure increased a little bit,but the engine runs not so smooth as before.

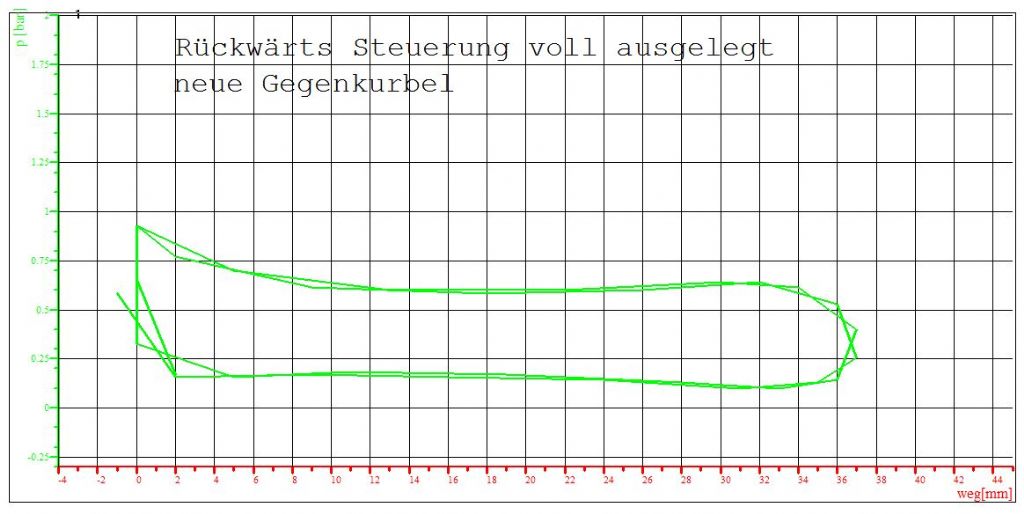

In backwards direction the engine behaviour is not so good. The pressure increased to the end of the travel and the timming is not correct.

But it is better as before the change.

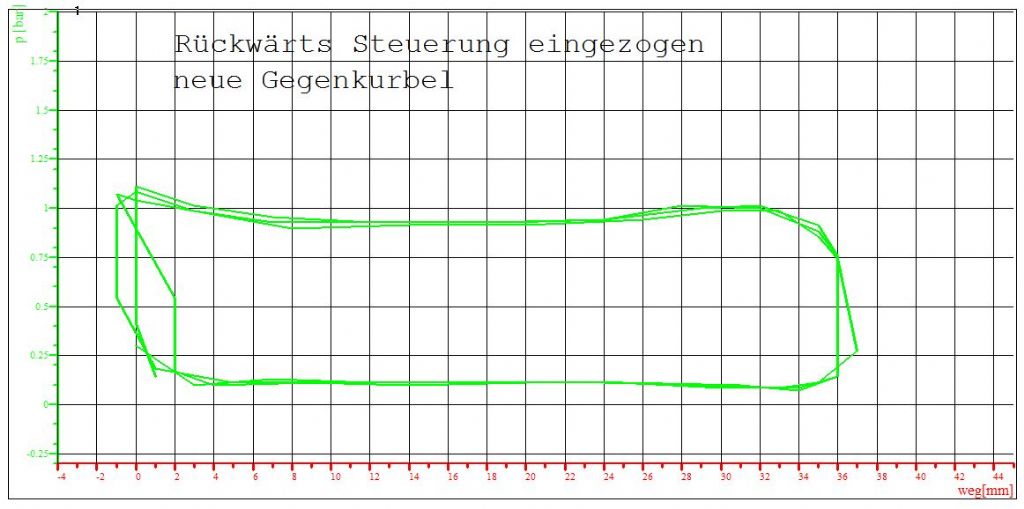

With the reverse lever to the middle position there was some compression to the end of travel. The engine behaviour is not so smooth as forward.

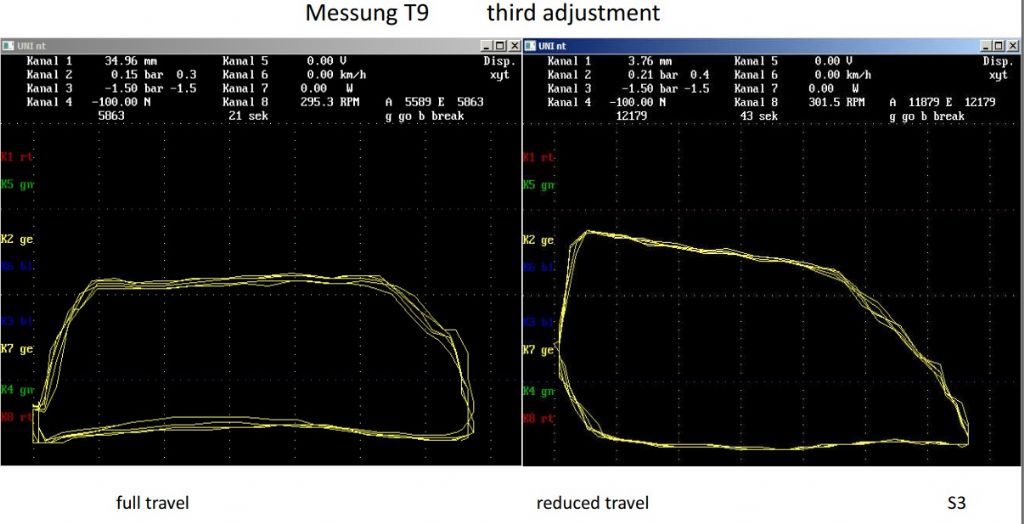

After the mesurements I change the position of the exentric a little and the behaviour was then better.

In the next days I will make a test run under steam to see how comparable is the experience with air to steam.

With steam it have to be much better. But if the principle adjustment with air is the same as with steam it is more easy to do and to measure.

Werner

Werner Schleidt.