Posted by Richard B on 10/09/2023 13:02:02:

Andy,

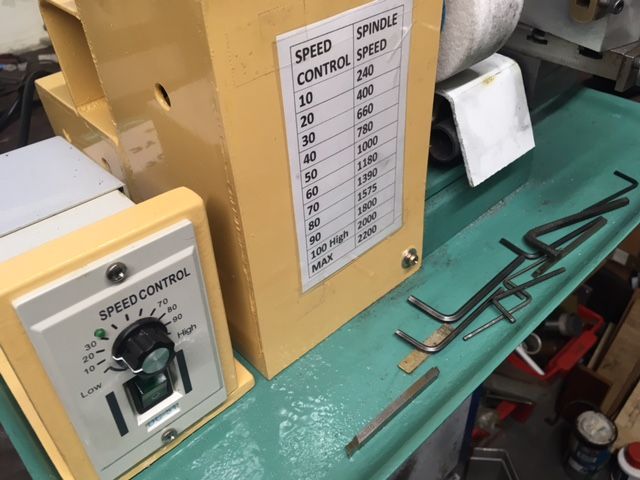

I have also used that supplier and had good service, I decided I would rather have a plastic enclosure for the controller and sourced the one in the pics.

Its actually an old early Perris lathe that I use to touch up lathe tools etc.

Thanks for all the replies on this.

I think I'm down to two options. 1) the brushed motor kit in my earlier post or 2) the Jack servo motor Clive pointed me towards. As I currently see it both have their different advantages and "disadvantages"..

I like the relative simplicity of the brushed motor kit coupled with the relatively simple and easily replaced electronics should that unit fail. On the other hand, the maximum speed (since the lathe shouldn't be run above 1000 rpm) needs to be controlled by pulley selection and/or a position limiter on the potentiometer. The fact that torque is reported to be good down to around 400rpm suggests the optimum set-up might be to arrange pulleys so as to achieve minimum lathe speed at a motor speed to 400rpm.

On the other hand I like the Jack (or similar) servo motor option as I believe these can be programmed to limit maximum speed, which eliminates the need to implement something separate to prevent speed being set too high for the lathe. Also, as I understand it, the exact required speed is achieved by programming (setting) the required speed rather than having to calibrate positions on a potentiometer dial. But, the electronics are far more complex/specific to the motor so if they fail (maybe rare occurrence I know) one is probably more reliant on the original supplier.

Richard B – particularly interested in your reply as I was scouring the Internet yesterday afternoon looking for alternatives to the brushed speed controller provided in that kit and, coincidentally, the one I homed-in on was the unit you are using (with delivery from UK stock). So, it's good to find someone that has used that. Reason I was looking for an alternative to the supplied unit was: 1) because of the 100Hz noise problem Peter Cook mentioned and 2) I wasn't convinced it looked sufficiently robust. Does your unit eliminate the 100Hz spike problem. Also, does it dissipate a lot of heat – I wondering if it would be cope with being enclosed or whether it needs free air-flow all round?

So, as always there are choices! I've not yet decided but currently slightly favouring the brushed motor kit (with later replacement of the controller).

But, in the short term, a moment of common sense struck over the weekend. As this project is restoration of a newly acquired lathe which I have never used it occurred to me it was probably sensible to get it set-up with the original hefty motor and counter shaft to confirm there's no issues with the lathes before I spend money on a replacement motor! It will only be a very temporary lash-up (very literally) to get the lathe spinning – started over the weekend but a bit more to do.

Andy

Richard B.

.

.