This is my first post although I have often ended up in these forums when searching for advice.

I've had a Flexispeed Mk1 for a few years but have recently bought a Flexispeed Mk2 to restore and replace it. The restoration has now started and the lathe is now stripped down except the headstock. I am having trouble removing the spindle.

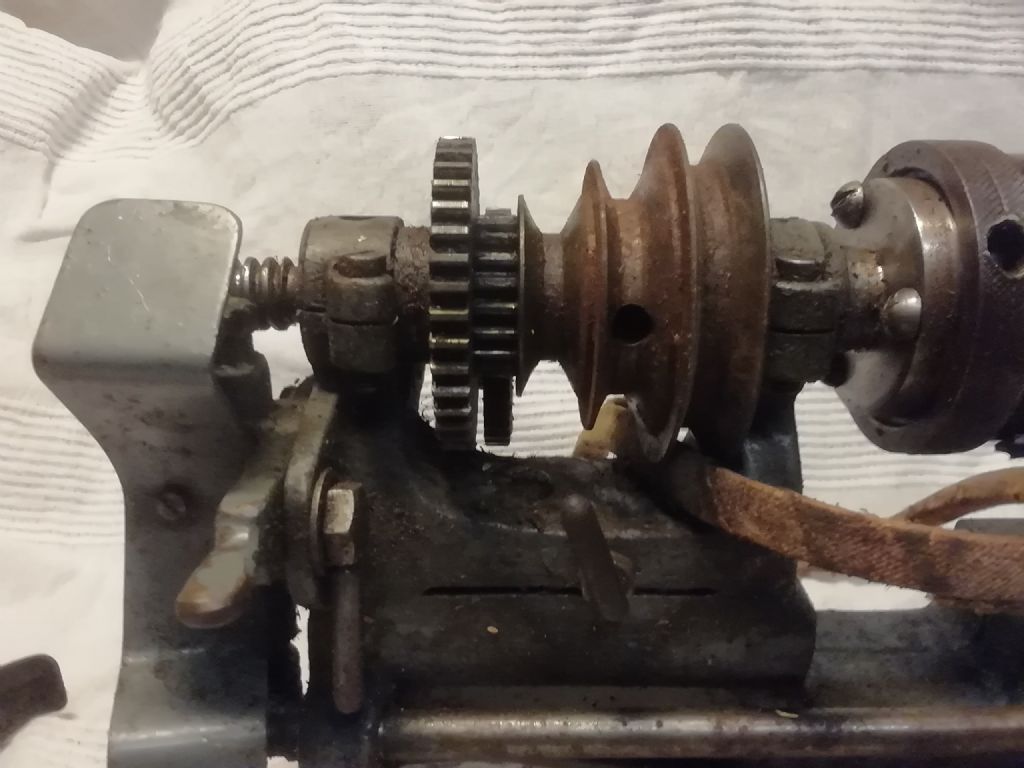

The starting point is the large gear is a very tight fit on the spindle, whilst the pulley and attached smaller gear are a freely rotating fit. Applying some tapping to the end of the worm (left of headstock) whilst holding that large gear to avoid headstock damage, moves the spindle to the point that the large gear is no longer tight on the spindle and will rotate: this step is quite easy. But if I continue with this tapping by the time the end of the spindle worm is just about flush with the headstock bearing I find the pulley is then VERY tight on the spindle.

Questions are how to proceed and have a missed something here meaning I am going about this the wrong way? Should I support the pulley somehow (to avoid damage to the right hand side of the headstock) and continue knocking the spindle through?

It seems to me this has to have been assembled in the first place by the reverse of the procedure I'm trying to follow now so I'm a bit mystified as to why it's so very tight although it seems to me there must be a section on the spindle that is slightly larger diameter.

As I know there have been various threads related to Flexispeed lathes in these forums I am hoping someone can offer some advice on this particular problem. Any help would be greatly appreciated.

Andy

Andy

Neil A.