Posted by John Hinkley on 17/03/2021 16:20:47:

Sorry to disagree, but I don't see how the boring bar will produce a flat bottom, unless the bar and cutting edge is half the finished diameter of the hole, or less without the outer edge of the bar contacting the "far side"of the 0.6" hole. That is 0.3 ". The insert boring bar in the photo looks far wider than that to me. I would venture to suggest that using an end mill will give the best result and even then the bottom of the hole will be slightly convex due to the nature of the grind. That probably won't matter a great deal and I doubt it will be seen, either. I won't tell, if you don't.

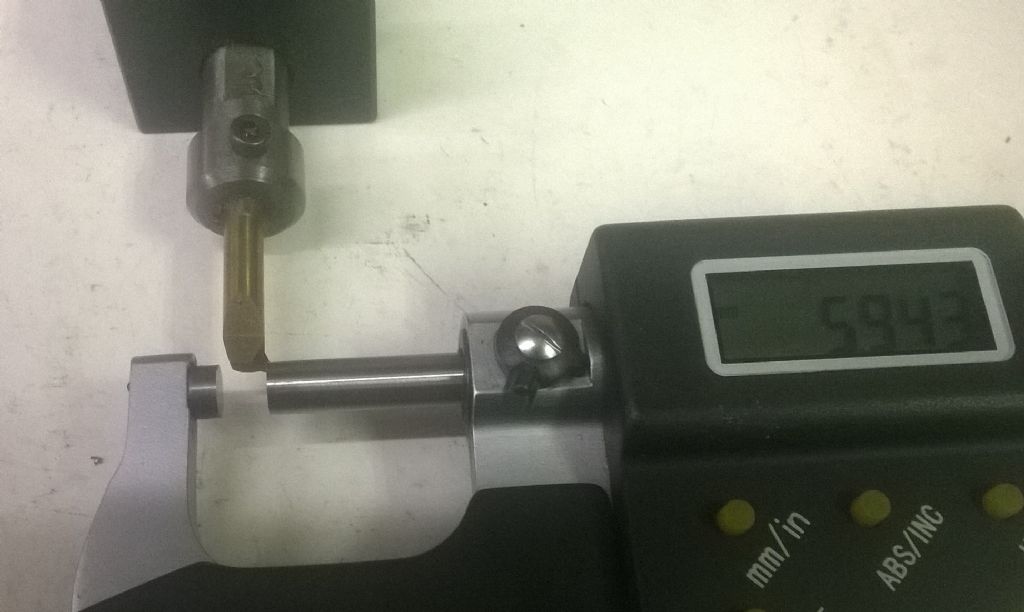

I have a small Sandvik boring cutter which is about 6mm across the end which might just do the job without the cutter contacting the opposite side of the hole..

Not a very good photo, I'm afraid. The micrometer reads 5.943 mm. This would do the boring and produce a flat bottomed hole as well. I would drill to 10mm, the tip of the drill to required depth, then use the boring cutter to finish the hole to size and form the flat bottom at the same time.

John

Edit: Jason posted while I went out to take the photo!!

Edited By John Hinkley on 17/03/2021 16:22:06

I've got a couple of those Sandvik tools, and a holder (Coroturn XS CXS-A10-05). The inserts for it have a chamfered end – I could have sworn mine were for internal threading. Perhaps they are, but you can get also boring bar inserts for them. I wonder what the difference is? Do you happen to know what catalogue # your small Sandvik boring bar is?

I've had it years, and only tried internal threading with it last week (unsuccessfully). I ended up using an HSS tool, and eventually I had some success. I think the tool I have was too small for the thread, and it was in aluminium, which seemed to tear very easily. I couldn't get a clean cut with the Sandvik insert.

JasonB.

JasonB.