I'm fed up with trying to count the marks on the scales on the wheels of my Sealey 2502 and the temptation to everything 'by eye' is great!!! So I am getting three of the fairly cheap magnetic DRO scales with remote display that Arc Euro sell.

The 2502 is more or less the same as the Seig models and the Arc Euro parts seem to be the right sort of size to nestle in, out of the way. But I have a slight dilemma which anyone who's done the same installation would probably have an answer for.

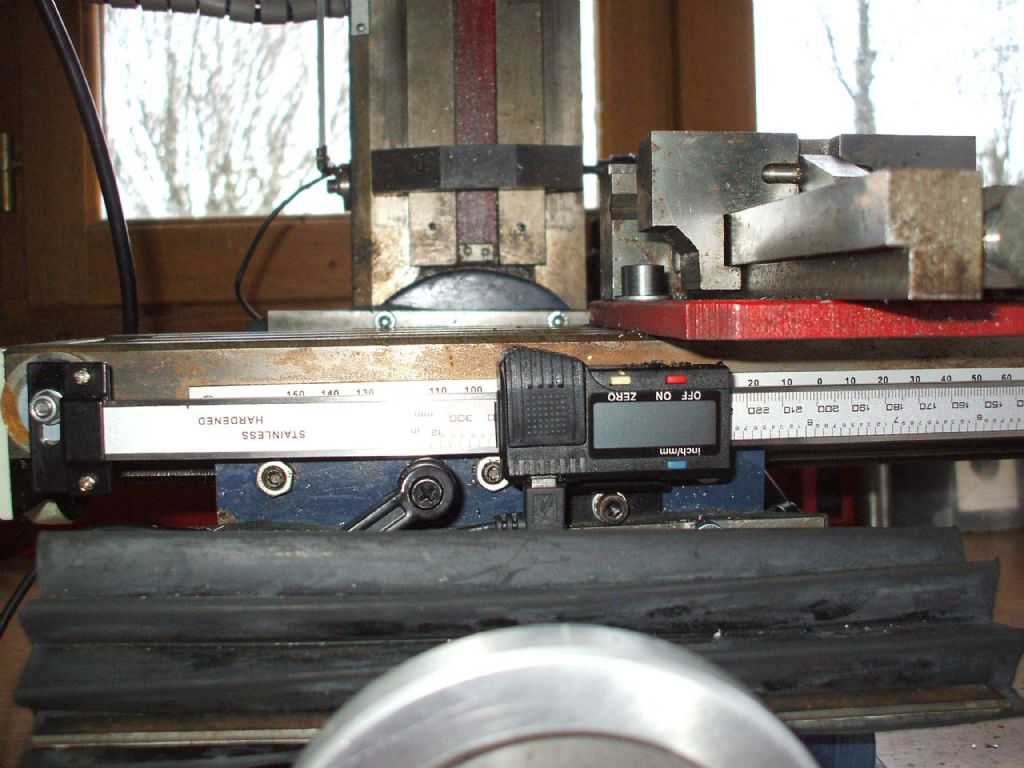

The short one I have bought fits the X axis with no problem or modifications and a long enough one (Z) will fit the vertical column in a position just behind the operating lever with a bit of a spacer involved. In both those case, the scales will be stationary.

However, the Y scale is the right size to screw onto the Y table and the slider will need to be fixed, somewhere on the left end (away from the wheel end). Afaics, the scale will fit in without limiting the X movement as long as the slider is out of the way. But that only works with the concertina swarf guard removed. That rubber stuff actually gets in the way, even on its own..

So it seems that I need an alternative sort of swarf guard apron thingey. It's all a bit cramped round the back and things should really be kept below the level of the table to clear my milling visa when it's there. What would do the job is a guard that's fixed to the moving table, rather than the present arrangement that's fixed to the column – as normal.

A few photos would help me a lot – plus any comments about how well or badly your various systems behave. It would make me very grateful.

P.S. I should add that there are a number of videos which show people mounting DRO on a minimill but none of them seem to mention the problem of restricting the cross axis movement due to the DRO scale. IT's only 100mm to start with and ten or fifteen mm lost if you want to protect the dry from being squashed, that's a pain in the X axis.

Edited By andrew lyner on 28/07/2021 15:20:08

andrew lyner.