It's been a while since I last posted, BUT I've achieved a landmark in using the lathe.

Chuck back plates

I've had chucks gathering dust waiting for me to machine backplates for the lathe and dividing head, so decided it was high time to start machining the 4 ready screwed backplates I got from Warco and making two for the Bertex Dividing Head.

Machining the OD of the last Warco one, using power feed, I selected Saddle feed in error rather than Cross-slide and a big dig-in was the result, BUT the brass tube I used to replace the spring pin didn't shear as I had hoped it would. (Need to think again, and maybe time to fit that clutch to the Gearbox input shaft now.)

Ideas on a replacement waisted spring pin design please. To

I panicked a little, as expected following on from my first episode, and instead of pulling the clutch lever to disengage motor, I made a grab for the Feed Shaft lever to disengage the Feed Rod.

After recovering from the 'shock' I found that it was now impossible to engage the Feed Rod no matter what I tried or how much effort I exerted, so I finished off in manual mode and walked away, working on the Austin Seven to take my mind off what further damage I'd done inside the Apron.

With the Carport at 27°C & 80% humidity during September, it just wasn't conducive to working on the Austin Seven, so Workshop time.

I wasn't in the mood to remove the Apron once again, to look inside, so settled on finish machining the backplates in 'manual' mode.

Imagine my delight and surprise to find that the Feed Rod Lever was completely free and back to normal with no hint of it having locked up.

I can only surmise that when I made that lunge to disengage the Feed Rod lever I must have inadvertently made contact with the Half-nut lever, thus partly engaging the interlock.

Those two levers are next to each other, albeit the Half-nut one on is on the side of the Apron.

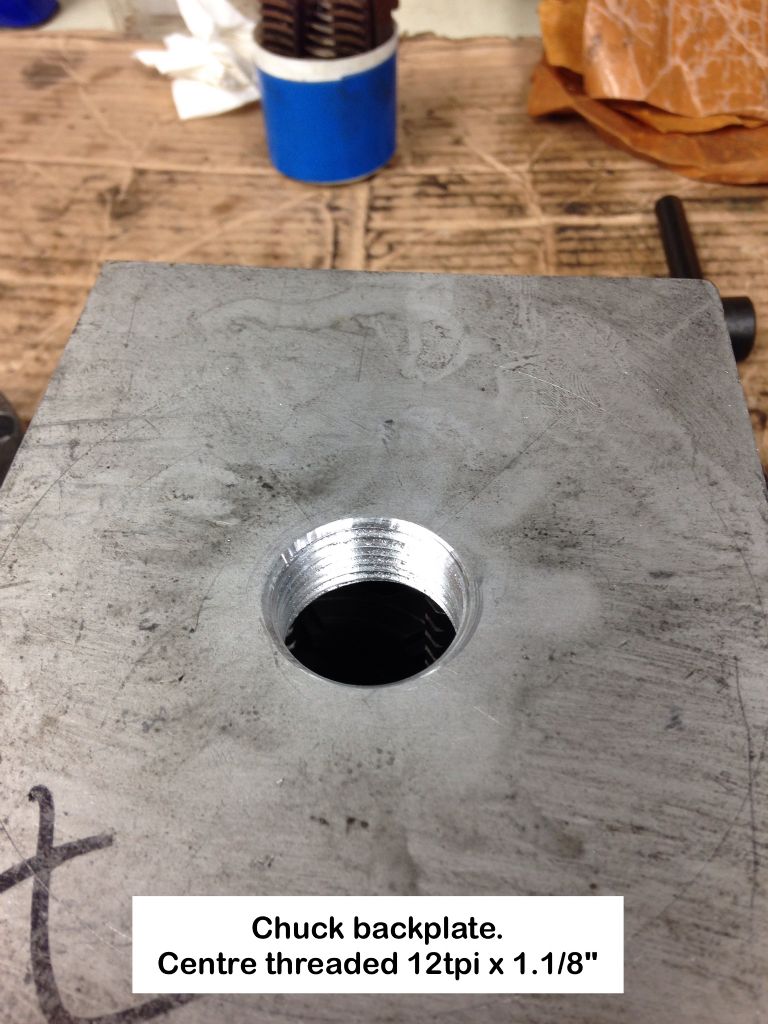

Soon had the backplates for the lathe chucks mounted and registers done, then time for the Vertex dividing head ones and they had to have a 12tpi thread to fit spindle.

No way was I forking out for Myford chucks/backplates, so procured a 4" 3-jaw Pratt plus a 6" 4-jaw Bernerd.

This meant doing some screwcutting in the lathe for the first time believe it or not, as I've been able to get away with using taps and dies till now, and quite frankly funking the very thought to boot.

Geoff – Continued, with photos, due to word limit.

Michael Cox 1.