Thanks for all the encouraging comments, chaps.

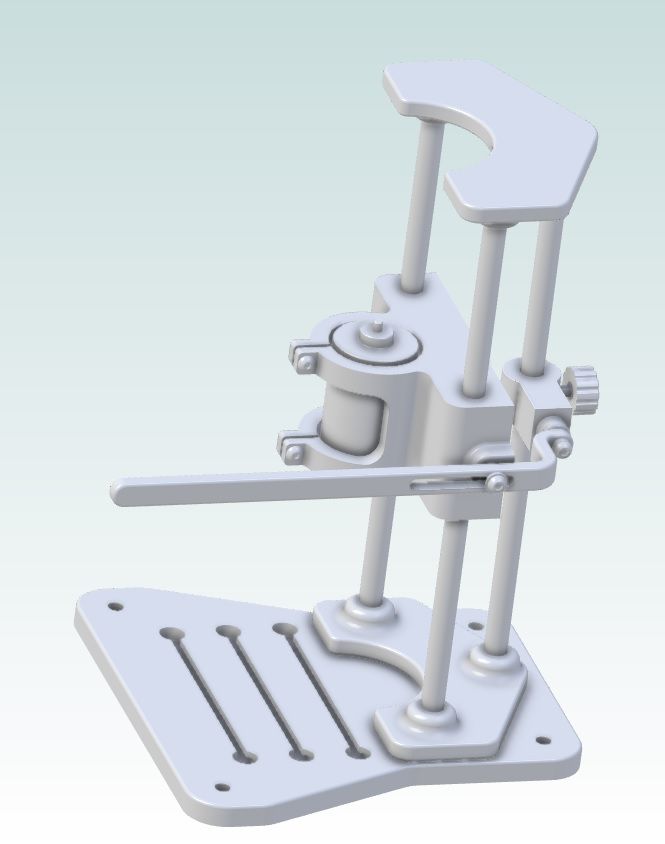

Perhaps I should have been a bit clearer with my description. The three vertical columns are Ø12mm steel tubes to provide a bit of stiffness to the structure, but as I said most hole drilling will be to bring printed hole to size for tapping drills and clearance hole for the bolts, so not a lot of stress on any of it. Having said that, the proof of the pudding will be when I start using it. Time will tell.

Neil, I bought your 3D printing book some while ago and am about to start re-reading it to refresh my understanding of the materials and their various properties. So far I've only used basic PLA, because that was what was supplied with the machine (which, incidentally is a Bambu Lab X1 Carbon). I did try some carbon fibre impregnated filament without any success so went back to the basic stuff to get me going. More experimentation needed with settings.

John Doe2. Not my fist foray into CAD by any means, just its use to create STEP files for printing.

By the way I'm using Orca Slicer to produce the G-code and sending the files wirelessly to the printer. It also takes a micro SD card but, again, that's for the future. Some users are wary of sending their files via the cloud and I can't say that I'm overfond of the procedure.

John

Peter Cook 6.