Hi Michael,

Here’s one which will fall into the category of `grandmas and eggs’, and which is already generating in my mind, “What have I started here?”.

However, I have to ask “How important and how accurate is setting the cutting tool to the centre of the workpiece?” Do I hear growls of resentment?

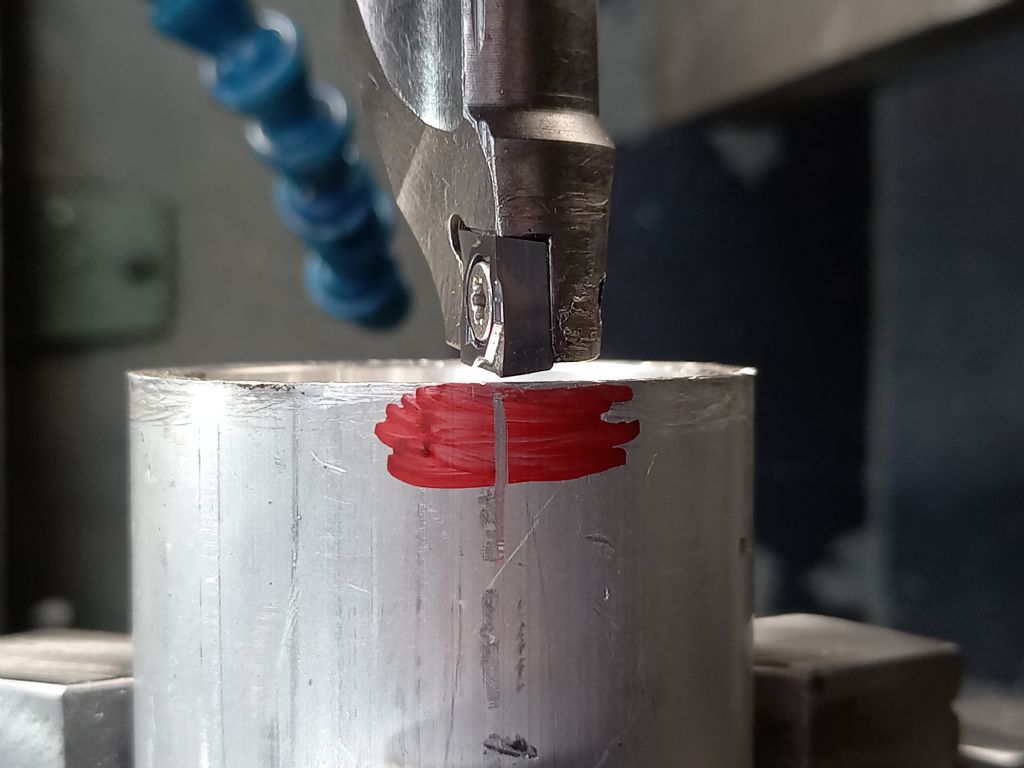

I must also preempt and simplify my comments by suggesting that we consider a basic lathe setup for surfacing, ie. reducing the diameter of a short length of bar projecting unsupported (cantilevered) from the chuck.

To start with, in every situation when metal is being removed by the `cutting’ process (which is not really cutting anyway), stresses act upon every part of the machine, the tool, and the workpiece. These stresses translate into strain (deflection/movement) of every component involved. They will also to some degree, take up any slack in the machine.

Clearly, the stresses generated will be in opposite directions, starting at the point of contact between the cutting tool and the workpiece. For simplicity and my own limitations, the actual direction of the resultant force is a combination of three forces generated at the cutting tool tip. In other words, there is the (main) downward force on the tool, there is a sideways force mainly from the feed, and a `backward’ force pushing the tool away from the workpiece. By definition, there will be an equal and opposite resultant force in the workpiece.

For all sorts of reasons, I believe it is important to note here that, relative to the cutting forces, the deflection of the projecting bar (at its tip), will be proportional to the cube of the projecting length, and to the fourth power of the diameter. Similarly, the overhang of the cutting tool (also cantilevered), will add to the deflection in proportion to both the length of tool overhang cubed, and the vertical `thickness’ of the cutting tool cubed. Don’t be surprised if the workpiece is somewhat thicker at its tip than close to the chuck.

With these factors in mind, it is easy to see that the question of centre-height accuracy is controversial.

So, relative to the style and sharpness of the cutting tool, the depth of cut, the surface speed of the workpiece, the feed rate of the cutter, the material being cut, and the presence (or otherwise) of lubricant/coolant, (there could be others), we have a situation where the workpiece will lift by some amount, and the tool will dip by some other amount.

And by how much?

Suffice to say that IF the tool is always too high under any conditions, the front face of the tool will rub against the workpiece. The converse is perhaps preferable and, as a result of the above comments, will take place regardless.

Anyway, keep your `cutters’ sharp gentlemen!

Sam

Sakura.