I'll usually run a Dremel with orange teardrop shaped stone in it lightly over the surface to remove and high spots which is usually enough to get a paint finish that still looks like it was a casting as there will be some slight surface irregularities. You can do more if you want a mirror smooth painted look. Scale also comes into it as a casting from a half scale traction engine will tend to need less prep than a 1/12th scale model to get the same size original cast finish to look right as the same sand is used for both castings

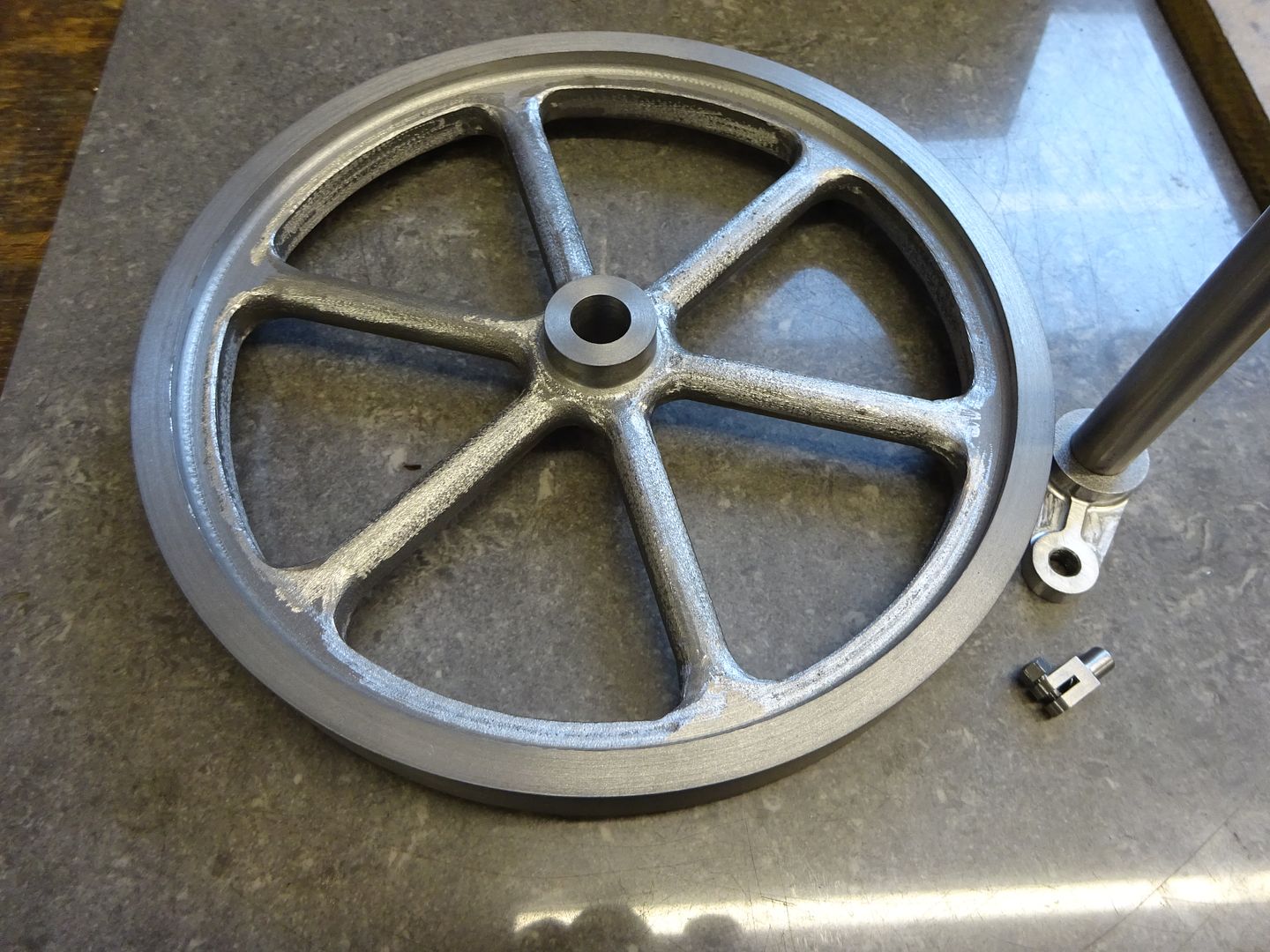

I did a Stuart 7" flywheel last weekend this shows it before. A good casting with little flash and well lined up halves, flash was filed off before machining, dremel after as I wanted to also blend in the turned surfaces that will be painted with the cast ones.

And after

That will most likely get a coat of high build primer, rub down and then final prime and colour.

This thread goes into a bit more detail of how I finish castings and a few of their "features"

Edited By JasonB on 15/01/2022 07:19:47

James Hall 3.