Bob,

You don't need a second encoder – lets take a look at the basics of most ELS systems.

Using an ABZ encoder which has an A and B quadrature channel pair , and a Z or index channel is how most ELS systems do it.

The index is used by the ELS to sync the leadscrew stepper so the threading tool enters the workpiece at the same place each time. So it does not matter where the tool tip is placed in relation to the work piece – ideally it is position a few thread pitches from the thread start. But is does not have to be the same position each new threading pass. So you could set it say 10mm from the start, do a pass, then return and stop say 5mm from the start and it will still be OK. As long as the halfnuts are kept engaged, the ELS will wait for the index pulse, and then in the space leading to the thread start in the workpiece, it will accelerate the leadscrew stepper such that the leascrew is at the correct speed ( for the spindle speed and chosen thread pitch) and at the correct position when the tool tip enters the workpiece.

The AB channels ( you can get away with only A in you never thread in reverse..) are generally a high number or pulses per spindle rev – around 2000 to 4000 or so pulses. These pulses are used to generate the stepper pulses ( and pulse rate) via a divider or via Bresenham's given the desired thread pitch and spindle RPM, which is measured by means of said encoder. Likewise, it does not matter where the thread end is – you only need it to be in the same place each time , esp if threading to a shoulder.

In reality is is a simple task for the ELS to keep track of the thread end, thread start, threading in process and threading done mechanisms, so having hards stops, or any other form of stop is superfluous.

mine works as follows –

Set tool tip at thread start point, say 6mm from the shaft end. Press Thread_Start. Jog ( Via ELS button or handwheel) the tool tip to the thread end position, press thread end. An led lights up, indicating 'go to thread start' Press button to go to start – carriage rewinds to start. An led lights indicating ;Start Threading'.

Start the spindle, press 'Start Threading' button, with depth of cut set.

Tool reaches thread end, carriage halts. Retract tool, prees 'go to start' button, carriage returns to start position and repeat.

I use a jog wheel to set the start and end points and to select thread pitch etc..

Threading with ELS can become 'boring' – no more butt_clinching, so it needs to be simple to use, no complex settups, etc – all so you don't get sequences wrong cause you are thinking of other things..

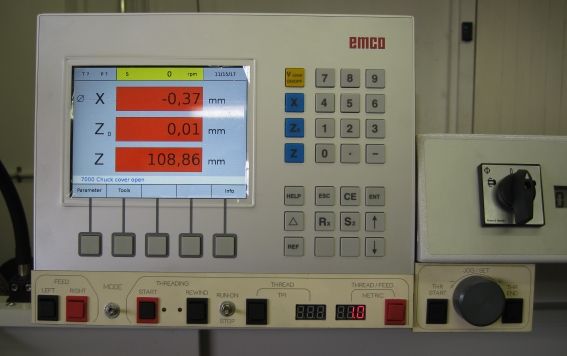

ELS is long narrow panel below the DRO.

This is the same ELS system, fitted to my smaller EMCO lathe.

Martin Connelly.

Martin Connelly.