various comments.

Jason makes the very good point that it is unrealistic to to expect a small machine, such as 450 watt mini lathe to remove metal at the same feeds and speeds as a larger, heavier and more rigid machine with a more powerful motor.

The manual for my mini lathe errs very much on the side of caution, by advising 0.010" (0.25 mm ) as a roughing cut!

With regard to the Diamond Turning Tool. To most model engineers this would mean a Tangential Turning Tool. Diamond being the trade name applied to one marketed by an Australian Company, and imported into UK, rather than a tool with a mineral diamond tip.. Such tools do exist and are used in industry for high spec, high precision turning on such things as I C Engine pistons

Tangential tools are highly thought of by those whom have experienced them. For many, that has become their general purpose turning.tool. The "Diamond" nomenclature stems for the fact that when sharpened, by grinding the square HSS toolbit at an angle, a diamond (Lozenge ) shaped face results.

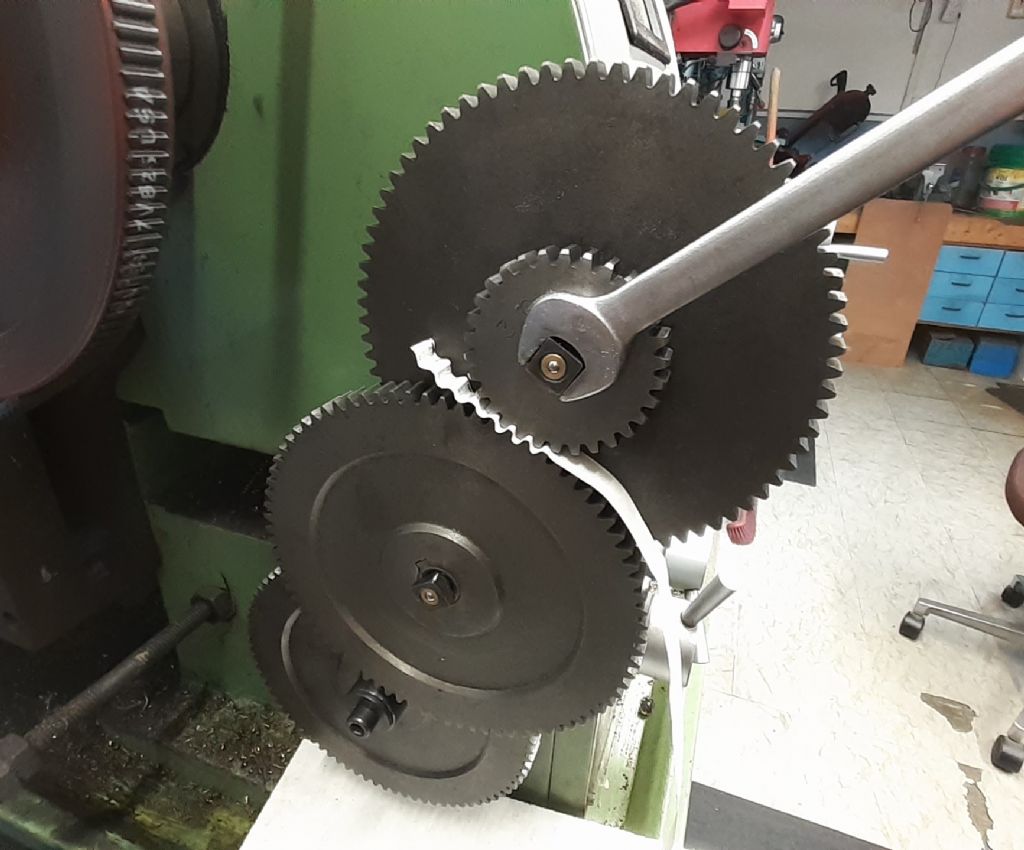

By all means find the gear cover and refit it it, if only for the sake of safety and cleanliness. Those are among the reasons why the manufacturer went to the trouble and expense of providing it!

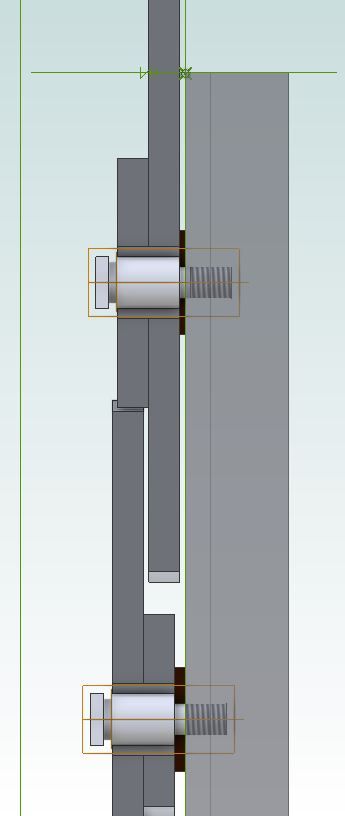

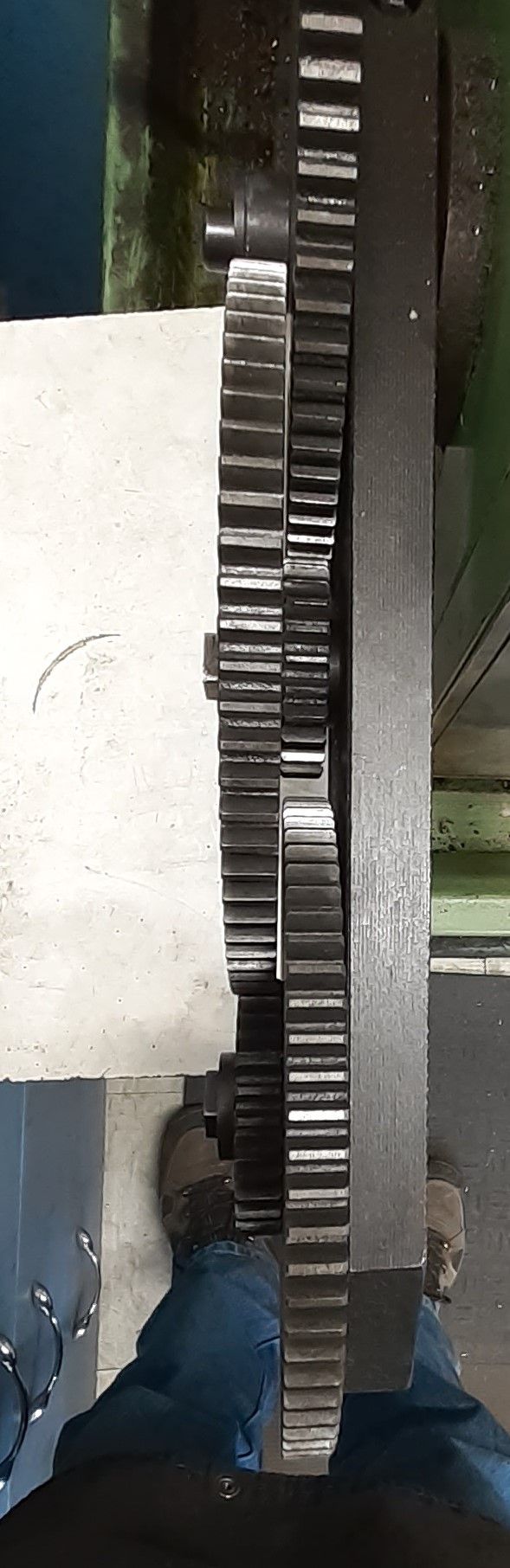

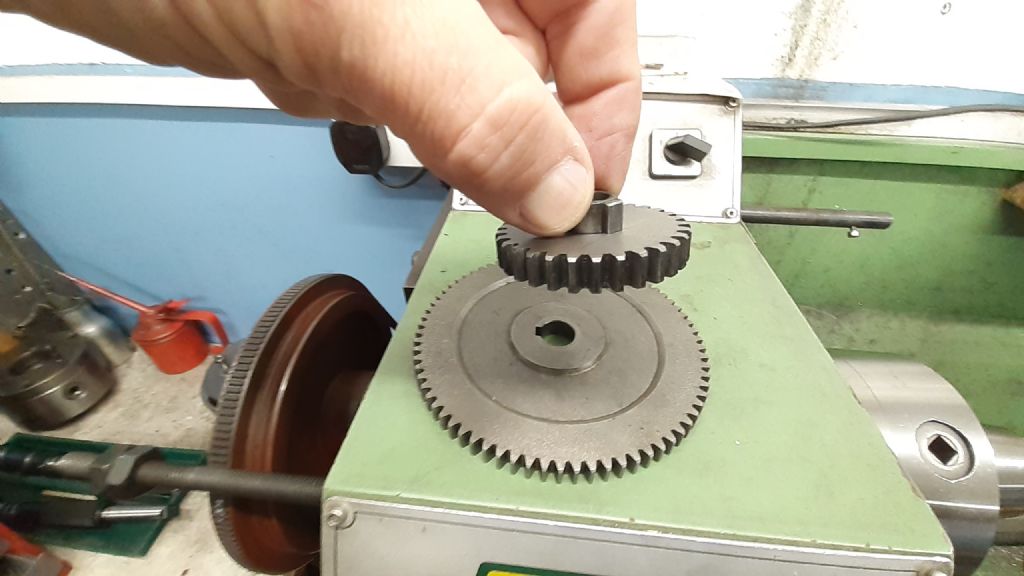

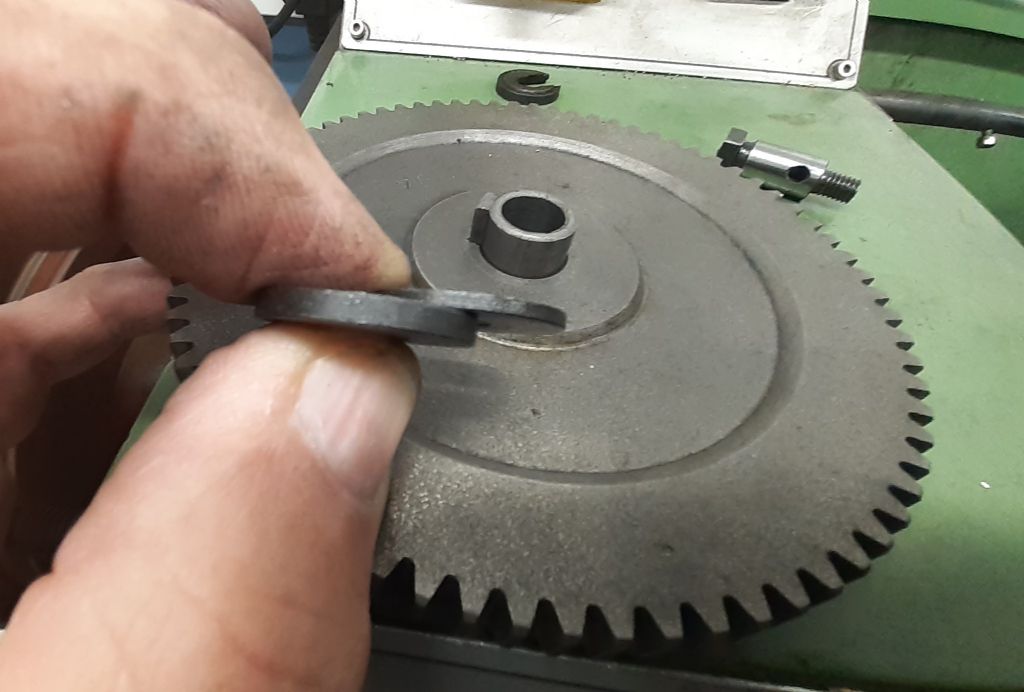

The table will provide details of the gear trains to set for various threads and feed rates. By acquiring extra gears, it will be possible to set up trains for further variants.

(My lathe says that the coarsest pitch that can be cut is 3 mm By replacing the normal 40T input gear to the Norton box with a 30T (supplied with the lathe! ) it was possible to cut a 4 mm pitch thread for a p;articular job..

Similarly, a mini lathe, with a Metric Leadscrew, can cut Imperial threads, (or vice versa ) by including a 63T gear in the train. It is not as precise a using a 127T, but the errors are acceptable for many purposes. .

Setting the gears by with a sheet of paper in each mesh will provide acceptable backlash, to drastically reduce noise and wear. Using a thick gear lubricant will further improve matters, and this is where the gear cover comes into it own, in containing any lubricant that is flung from the gears.

Don't despair, when you become familiar with the machine and how to set it up, you will find that can be a very useful tool.

It may not be perfect, hardly any any machine is. There will always be a job that is not ideal for it or is impossible to do on it. You can't swing a 150 mm job on a non gap bed machine with a 100 mm swing over the bed.

But, you will be amazed at what a skilled operator can do on a fairly modest machines!

At the other extreme, today, I have thinned the head of 10 BA bolts, held in 6 a inch 3 jaw chuck, on a machine capable swinging 12" over the bed! . Looks ridiculous, but the chuck can 10 BA nuts!

Learn how to get the best from your machine before damning it. The Industrial Revolution grew using machines far less sophisticated than your!

Howard (alias Fat Fingers

Edited By Howard Lewis on 05/11/2021 20:19:15

Howard Lewis.

![20211106_120830[1].jpg 20211106_120830[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/900988.jpg)

![20211106_120849[1].jpg 20211106_120849[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/900989.jpg)