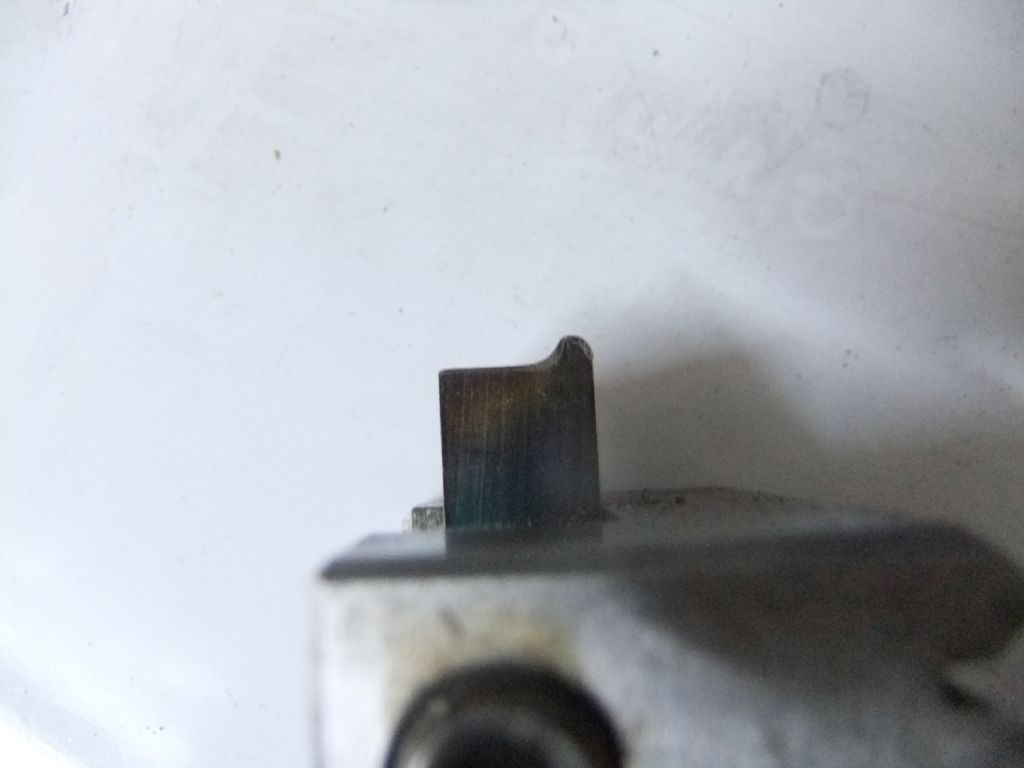

Been busy with the last part of the con rod and that is a bronze big end split bearing. The small dots are there to make sure that when it is taken apart to assemble the complete model they stay in the correct orientation

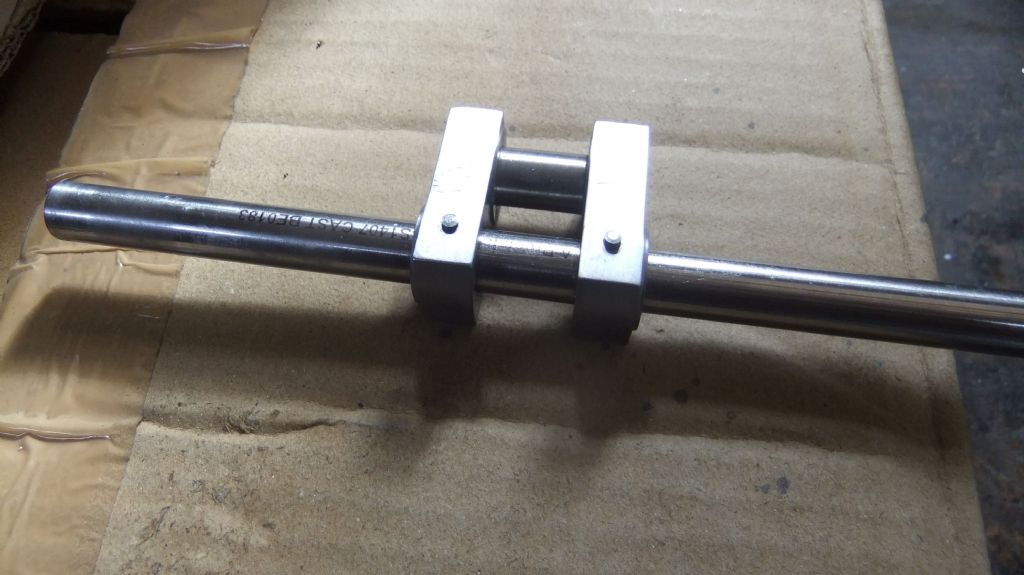

Then it is onto the crankshaft assembly, the plans show it mad from a single piece of steel but I have decided to make it up from two small pieces and some silver steel.

First was to make the two webs made easy by the use of a small home made stop which worked a treat.

Turning the raised sections as well as the curve on both ends I had to do this set up 4 times two for each piece

After the part being deburred I am pleased with the result

All the parts for the crank shaft assembly

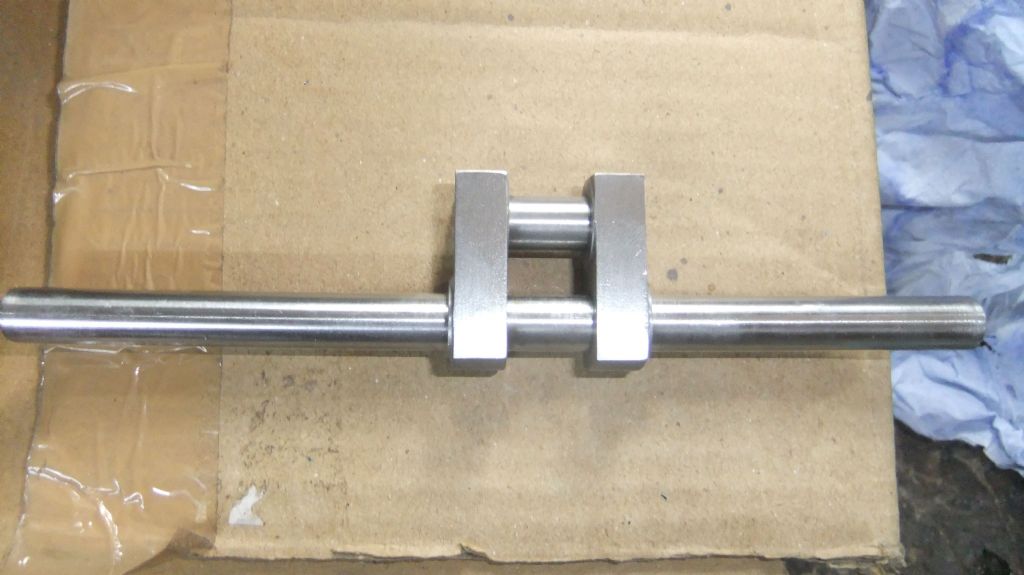

A dry fit to check everything was in line. I have left the main shaft in one piece until it is finally fitted together. I will locktite them in and also drill for a tapered pin in each of the joins. The two pieces at the top of the photo are just machined to the correct width for the gap in the middle.

Still more to do to this once it is finally fitted together

Dalboy.