Posted by Peter Cook 6 on 22/12/2022 22:37:06:

No more "cheating" than any other mechanism used to get the pendulum to accurately match a GPS derived time signal.

As you said a few posts further back in the discussion about PID control to deal with long time constants, "The clock compensates on every beat". So every beat you are adjusting the power to keep the pendulum in sync with the time standard. I was just suggesting a different (and possibly simpler) way to do that.

…

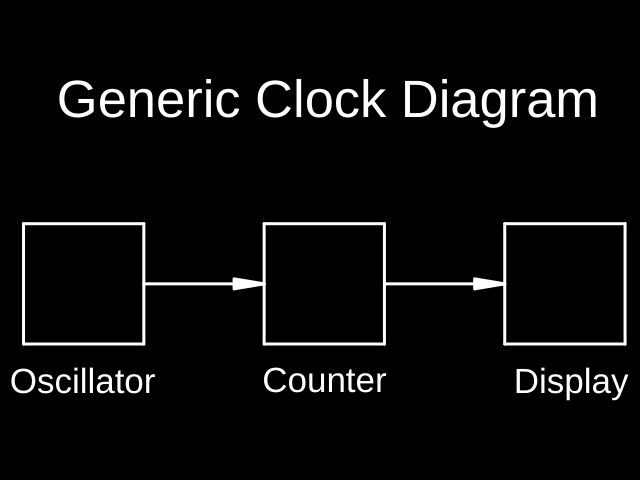

Ah, a misunderstanding! Here's a block diagram of a clock:

Typical oscillators are the earth's rotation, pendulums, balance wheels, quartz crystals, and the vibration of certain atoms. The perfect oscillator is stable, it doesn't drift, jitter, and it maintains a steady output no matter what. There is no perfect oscillator. Pendula are sensitive to temperature, air pressure, vibration, tidal effects, and possibly humidity. All friction is bad, as is any physical change in the bob, rod or suspension.

The counter is any device that counts beats and divides them into something useful such as Hours, Minutes, and Seconds. It also allows the clock to be set to a particular time. In a mechanical clock the counter is a fixed ratio gearbox.

The display is any device that converts the counter output into human useful form – the hands of a clock, or a digital display.

It's important to isolate these stages from each other. The Display mustn't effect the Counter, and the Counter mustn't effect the Oscillator. This is quite difficult to do in a mechanical clock, and pendula are very sensitive to outside influences, especially impulses, temperature and air pressure.

My clock minimises impulse problems by removing all physical connections to the pendulum. The escapement is replaced by an Infra-red beam and an electromagnet. I have accurate control over when the pendulum is impulsed, and impulse strength. In practice so far, these have been reduced manually to the point where the clock runs reliably. They could be used synchronise the pendulum to GPS, but aren't.

A conventional pendulum clock compensates for temperature mechanically in the pendulum, usually by exploiting the different expansion rates of two metals. One way is to partially fill the bob with Mercury. When the temperature rises the rod expands and would alter the timing, except the Mercury also expands, lifting the bob's centre of mass by rising inside it, and counter-balancing whatever the rod does. I'm not doing anything like that.

Instead of compensating the pendulum, I correct it's errors in the counter. My counter is a microcontroller, where the ratios are implemented in software. In addition to counting pendulum beats, it also reads temperature, pressure and humidity. After testing the clock over a long period, I know what the pendulum's period should be at any given temperature, pressure and humidity, and can compensate for them in the counter, not in the oscillator.

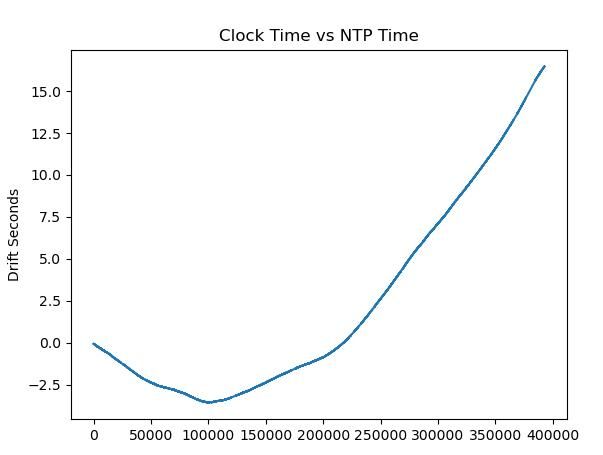

For this scheme to work the pendulum has to be reasonably well-behaved, which it isn't yet. I can compensate for reliable changes, but not for variations caused by unknown factors. This graph is giving me grief, it shows my clock is drifting and is fast compared with NTP:

What I don't understand is why the clock drifted slow at first, and then switched to drifting fast. It's not temperature or pressure related. If the rod were stretching or something like that the drift would be constant in one direction, not a tick shaped curve.

Forum friends have suggested improvements to my over simple suspension design, which could be buckling the suspension spring. When I get the chance I'll make a new one, but xmas and a family crisis are taking priority.

Dave

duncan webster 1.