Experimental Pendulum Clock

Experimental Pendulum Clock

Home › Forums › Clocks and Scientific Instruments › Experimental Pendulum Clock

- This topic has 561 replies, 22 voices, and was last updated 27 February 2023 at 22:17 by

duncan webster 1.

-

AuthorPosts

-

18 December 2022 at 16:51 #625348

Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133Posted by duncan webster on 18/12/2022 11:56:56:

.

As requested, not carping

.

… and not even discussing, now that I’ve done the searching for you.

Oh well

MichaelG.

18 December 2022 at 17:02 #625353John Haine

Participant@johnhaine32865Well I've had a go, using 3 Nanos, two implementing PPS generators with very slightly tweakable frequency and the third a modified version of the phase detector. Main mod is to Serial.print rather than using SPI to a Mega as I don't have one! What does "Tester()" do? So far I can't get sensible results so will have to shelve it for a few days – oh and them it's Christmas…!

18 December 2022 at 19:37 #625356duncan webster 1

Participant@duncanwebster1Instead of the GPS thingy, could one use the 1 second pulse from MSF (the ex Rugby time signal)

18 December 2022 at 19:40 #625358SillyOldDuffer

Moderator@sillyolddufferPosted by John Haine on 18/12/2022 17:02:26:Well I've had a go, using 3 Nanos, two implementing PPS generators with very slightly tweakable frequency and the third a modified version of the phase detector. Main mod is to Serial.print rather than using SPI to a Mega as I don't have one! What does "Tester()" do? So far I can't get sensible results so will have to shelve it for a few days – oh and them it's Christmas…!

After an interruption I'm back on the case. There are some issues with the code as downloaded from github.

- The Nano doesn't use SPI, so there's no need for the two #include statements or wire,begin() in setup(). Doesn't effect operation.

- setup() declares the interrupt pins as INPUT, which isn't necessary. Doesn't effect operation.

- sendToMega() uses a buffer, ltoa(), and Serial.write twice when the same could be achieved more easily with Serial.print(). Doesn't effect operation.

- sendToMega() doesn't end the data with a newline, causing each number pair to concatenate. I don't know how the Mega decodes this, but delimiting with a newline is easier to parse when debugging.

- sendToMega() is called from inside PPS_trigger(), which is an Interrupt Service Routine. This is bad practice because ISR functions should do minimum work to reduce the risk of itself being interrupted. Safer to set a flag causing sendToMega() to be called in loop(). Instead the calling function turns interrupts off whilst sendToMega() is running. This might cause problems, but the PPS interrupt is only called once per second.

- loop() calls tester(), which should be commented out. tester() simulates a 1 second pendulum pulse in software so that the code can be tested without a pendulum or signal generator. Not noticing tester() was being called may have caused my strange numbers.

After commenting out tester() the program produces no output at all. For some reason

attachInterrupt(digitalPinToInterrupt(Pen_sw), Pendulum_rise, RISING);isn't working, Pendulum_rise() is never called.

I'm not sure it's possible on a Nano to attach two different functions to the same pin at the same time. I think the second attach overwrites the first. In the past I've written a single ISR to process both rising and falling. It's attached as CHANGE, and starts by reading the pin (which has to be declared as pinMode INPUT). If the pin is HIGH, the interrupt was RISING, if LOW it's FALLING.

Dave

18 December 2022 at 21:01 #625361 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133Permit me to say, Dave [ et al ]

I am very impressed, and way out of my depth, observing this discussion.

MichaelG.

19 December 2022 at 13:21 #625404Martin Kyte

Participant@martinkyte99762Posted by SillyOldDuffer on 18/12/2022 19:40:18:Posted by John Haine on 18/12/2022 17:02:26:Well I've had a go, using 3 Nanos, two implementing PPS generators with very slightly tweakable frequency and the third a modified version of the phase detector. Main mod is to Serial.print rather than using SPI to a Mega as I don't have one! What does "Tester()" do? So far I can't get sensible results so will have to shelve it for a few days – oh and them it's Christmas…!

After an interruption I'm back on the case. There are some issues with the code as downloaded from github.

- The Nano doesn't use SPI, so there's no need for the two #include statements or wire,begin() in setup(). Doesn't effect operation.

- setup() declares the interrupt pins as INPUT, which isn't necessary. Doesn't effect operation.

- sendToMega() uses a buffer, ltoa(), and Serial.write twice when the same could be achieved more easily with Serial.print(). Doesn't effect operation.

- sendToMega() doesn't end the data with a newline, causing each number pair to concatenate. I don't know how the Mega decodes this, but delimiting with a newline is easier to parse when debugging.

- sendToMega() is called from inside PPS_trigger(), which is an Interrupt Service Routine. This is bad practice because ISR functions should do minimum work to reduce the risk of itself being interrupted. Safer to set a flag causing sendToMega() to be called in loop(). Instead the calling function turns interrupts off whilst sendToMega() is running. This might cause problems, but the PPS interrupt is only called once per second.

- loop() calls tester(), which should be commented out. tester() simulates a 1 second pendulum pulse in software so that the code can be tested without a pendulum or signal generator. Not noticing tester() was being called may have caused my strange numbers.

After commenting out tester() the program produces no output at all. For some reason

attachInterrupt(digitalPinToInterrupt(Pen_sw), Pendulum_rise, RISING);isn't working, Pendulum_rise() is never called.

I'm not sure it's possible on a Nano to attach two different functions to the same pin at the same time. I think the second attach overwrites the first. In the past I've written a single ISR to process both rising and falling. It's attached as CHANGE, and starts by reading the pin (which has to be declared as pinMode INPUT). If the pin is HIGH, the interrupt was RISING, if LOW it's FALLING.

Dave

I'm not sure it's possible on a Nano to attach two different functions to the same pin at the same time. I think the second attach overwrites the first. In the past I've written a single ISR to process both rising and falling. It's attached as CHANGE, and starts by reading the pin (which has to be declared as pinMode INPUT). If the pin is HIGH, the interrupt was RISING, if LOW it's FALLING.

I have no doubt you are correct to assume you cannot attach two different functions to the same pin. On the ATmega328 the External Interrupts 0 and 1 act asychronously to set two independent flags, have separate interrupt vectors and are configured exclusively either rising/falling edge or logic low level. The interrupt on change function is synchronous and can take up to 4 clock cycles to set the relevant interrupt flag. The interrupt vectors for interrupt on change are different to the asynchronous vectors. I have no idea how the compiler for the nano handles things but on a hardware level External Interrupt Pins cannot be set to both a falling and a rising edge at the same time. So yes you have to use Pin Change Interrupts to detect rising and falling edges.

regards Martin

19 December 2022 at 13:25 #625406John Haine

Participant@johnhaine32865I raised this question over on the Arduino forum and it seems that, no, you can't have 2 ISRs attached to the same pin! You would need either to use Dave's pin change interrupt or do an attachInterrupt in the ISR to attach the other one – messy!!

Looking at this and other issues in the posted code I wonder if this is an early version that hasn't been updated?

19 December 2022 at 14:11 #625409Martin Kyte

Participant@martinkyte99762It's not quite that you cannot attach two ISR's but cannot physically configure the hardware to do two jobs. There will be in the case of rising or falling edge anexclusive OR feeding the clock of a D Type Latch with the Rising/Falling Bit setting the function on one Pin of the XOR and the Pin input on the other. Detecting the Low state will be feeding the Pi signal to the Preset depeddent on that fuction bit being enabled. Whatever function is enabled creates an interrupt to the same vector. Reconfiguring within the ISR could be done but as you say it's messy.

regards Martin

19 December 2022 at 14:26 #625413John Haine

Participant@johnhaine32865Thanks for the clarification Martin.

On the whole given that the code as published doesn't seem to work and has some errors, and if it did I don't think it will handle asynchronous pendulums (important for anyone whose clock doesn't use a seconds pendulum by accident or design), I don't feel inclined to spend any more time investigating the method. I may raise the issues with the authors if they ever reply to my email. Dave and Martin, many thanks for your input.

19 December 2022 at 17:57 #625432SillyOldDuffer

Moderator@sillyolddufferPosted by John Haine on 19/12/2022 14:26:47:Thanks for the clarification Martin.

On the whole given that the code as published doesn't seem to work and has some errors, and if it did I don't think it will handle asynchronous pendulums (important for anyone whose clock doesn't use a seconds pendulum by accident or design), I don't feel inclined to spend any more time investigating the method. I may raise the issues with the authors if they ever reply to my email. Dave and Martin, many thanks for your input.

Thanks to Martin & John for confirming it's not possible to connect two different ISRs to the same pin at the same time. Switching interrupt type in an ISR is allowed, I agree messy. Another way on the bigger AVR chips to strap two external interrupt pins together and make one RISING and the other FALLING. Not enough pins on a Nano so last night I combined Chronova's two functions into one, and call it on CHANGE. Program produces output, but I don't know if it's right.

I think the code on github is a development version, not the final product, as John suggests. For example, looks like their debounce code has a bit missing. The code works on clean pulses, but it wouldn't debounce a dirty pulse.

Buglets aside, whether or not the logic correctly deals with John's scenario remains unproven.

Well worth looking at though – they've given me some useful ideas.

Not going well on my own project. I want to box up the OCXO properly and need a power supply and a divider IC. No problem with the PSU, I have loads of 7805 stabiliser chips, except they're all 7812. I've already had to order a new divider chip because the one I have is old-fashioned CMOS that barely does 10MHz even if extra volts are provided. Seems every time I need something my massive stock of electronic bits fails to provide. It won't be finished until after xmas now.

So, I've switched to making some software improvements, notably so that the analyser can work with either GPS or an OCXO or a DS3231 RTC (another awol part!) Good news, my workshop has warmed up so I could make the planned new suspension.

Dave

19 December 2022 at 18:40 #625441John Haine

Participant@johnhaine32865Dave, if you have any PICs Tom's picDIV code is on his website. There's a version that does 1 PPS from 10 MHz.

20 December 2022 at 11:11 #625495 John Doe 2Participant@johndoe2

John Doe 2Participant@johndoe2I realise this is not the point of your investigations at all, and I applaud your curiosity and endeavours; but if you are using GPS or whatever reference, and micro controllers running at n MHz, and an IR beam etc. to detect and correct minute pendulum errors……….why not just feed the reference pulses into the clock, and not bother with a pendulum?

Clock makers used pendulums because they were the most accurate counters at the time. But they were only accurate to within minutes or seconds per day or week, and now of course, we have far more accurate and consistent crystal oscillators and "atomic" clocks.

Regarding pendulum suspension; what about a magnetic levitating bearing? Would that be able to hold a pendulum pivot point accurately enough?

Secondly, what about engineering a way of physically changing the length of the pendulum to adjust for average swing changes? That would give you accurate time keeping over, say a 24 hr period, rather than trying to correct for every discrete swing?

Just thinking aloud.

.

Edited By John Doe 2 on 20/12/2022 11:12:23

20 December 2022 at 12:33 #625512SillyOldDuffer

Moderator@sillyolddufferPosted by John Doe 2 on 20/12/2022 11:11:27:I realise this is not the point of your investigations at all, and I applaud your curiosity and endeavours; but if you are using GPS or whatever reference, and micro controllers running at n MHz, and an IR beam etc. to detect and correct minute pendulum errors……….why not just feed the reference pulses into the clock, and not bother with a pendulum?

Clock makers used pendulums because they were the most accurate counters at the time. But they were only accurate to within minutes or seconds per day or week, and now of course, we have far more accurate and consistent crystal oscillators and "atomic" clocks.

Regarding pendulum suspension; what about a magnetic levitating bearing? Would that be able to hold a pendulum pivot point accurately enough?

Secondly, what about engineering a way of physically changing the length of the pendulum to adjust for average swing changes? That would give you accurate time keeping over, say a 24 hr period, rather than trying to correct for every discrete swing?

Just thinking aloud.

…

Ah, John beware! You're being sucked into the fascinating world of time-keeping!

My downfall started with an Arduino software project, intended to measure mechanical pendulum clocks as a way of detecting mechanical faults. There are at least two commercial products that do this, but I had in mind a MEW article allowing an amateur clockie to build one. As Grandfather Clocks aren't portable, the idea was that the tester would be plonked next to the pendulum and do it's stuff based on comparing what the pendulum did with an ultra-accurate source, which was GPS. Didn't work out because a really good GPS signal is needed, and this is only possible in my house close to a south facing window. The MSF radio signal isn't reliable enough here either.

The tester worked well on my dining table where I'd set up a crude pendulum on a Meccano frame. I was surprised at how well it worked, which led me to wonder how good a pendulum clock I could make using modern techniques. Is it possible to replicate the extraordinary performance of a 1921 Shortt Clock, using 21st century techniques? I'm not trying to build an accurate timepiece, I'm exploring how good a result I can get with novel methods.

John, Duncan and others have all built successful electronic pendulum clocks based on 'best practice'. I'm trying something different: for example my clock is much smaller and less rigid than conventional. Results are promising, but the effort has led me into all sorts of interesting byways and complications! The subject is far from simple, and it gets more difficult with each improvement.

Dave

20 December 2022 at 20:39 #625574duncan webster 1

Participant@duncanwebster1Posted by John Doe 2 on 20/12/2022 11:11:27:…..

Clock makers used pendulums because they were the most accurate counters at the time. But they were only accurate to within minutes or seconds per day or week, ……..

Secondly, what about engineering a way of physically changing the length of the pendulum to adjust for average swing changes? That would give you accurate time keeping over, say a 24 hr period, rather than trying to correct for every discrete swing?

Just thinking aloud.

.

Edited By John Doe 2 on 20/12/2022 11:12:23

Hmmm. Shortt clock was better than 1 second per year, Fedchenko was 0.2 ms/day, which is 1 second in 500 days. I haven't found figures for the Reifler, but it must have been pretty good, it was used as a standard in the USA until replaced by a Shortt.

0.2 ms/day is one part in 432,000. To get this change in period by altering the length of a 1 second pendulum you'd need to change its length by 1 part in 216,000. This is 0.0046 mm. A pretty tall order, which is why they added little weights to a heavy bob.

21 December 2022 at 09:25 #625617duncan webster 1

Participant@duncanwebster1Got my zeros wrong, 0.2 ms/day is 1 part in 432,000,000. I'd love to know how they measured this without an even more accurate clock.

21 December 2022 at 09:56 #625620Martin Kyte

Participant@martinkyte99762Posted by duncan webster on 21/12/2022 09:25:13:Got my zeros wrong, 0.2 ms/day is 1 part in 432,000,000. I'd love to know how they measured this without an even more accurate clock.

I guess it's from long term tests, if you measure over six months or a year you end up with an error you can measure from astronomical observations. It could be that some of the figures quoted were obtained afetr the advent of atomic time keeping to find out what was actually achieved in the past. Harrison used a mix of astronomical observations and the use of several clocks measuring variations between them and gradually bringing them to agree (or keep step) over a long period of time. A bit, but not entirely like, the 3 surface plate meathod for flatness.

It's an interesting question.

I feel that the gold standard for mechanical clock would be to be able to detect the tidal variations which I understand needs a variation of no more than 3mS a day. Tidal errors account for about 8mS variation but are usually lost in the noise for any but the best timepieces.

I may go back and read up on Harrisons testing techniques, I'm sure I have forgotten much of the detail.

regards Martin

21 December 2022 at 10:08 #625622John Haine

Participant@johnhaine32865Posted by Martin Kyte on 21/12/2022 09:56:28:…….I feel that the gold standard for mechanical clock would be to be able to detect the tidal variations which I understand needs a variation of no more than 3mS a day. Tidal errors account for about 8mS variation but are usually lost in the noise for any but the best timepieces.

I may go back and read up on Harrisons testing techniques, I'm sure I have forgotten much of the detail.

regards Martin

See this link for lots of info on clocks & tides:

http://leapsecond.com/hsn2006/

Shortt pendulums have been tested against atomic clocks using an electronic system to replace the Synchronome part, and post-analysis of the data showed that they could measure tidal effects.

21 December 2022 at 10:22 #625624John Haine

Participant@johnhaine32865Posted by John Doe 2 on 20/12/2022 11:11:27:Just thinking aloud.

.

Edited By John Doe 2 on 20/12/2022 11:12:23

"I realise this is not the point of your investigations at all, and I applaud your curiosity and endeavours; but if you are using GPS or whatever reference, and micro controllers running at n MHz, and an IR beam etc. to detect and correct minute pendulum errors……….why not just feed the reference pulses into the clock, and not bother with a pendulum?" – ah, that's the difference between a time nut and a pendulum nut!

"Regarding pendulum suspension; what about a magnetic levitating bearing? Would that be able to hold a pendulum pivot point accurately enough?" – Actually not much energy is lost in bending the spring, except perhaps at low amplitudes where air resistance has diminished. I did look at the magnetic possibility some years back – the problem is that you need a bearing that constrains the pendulum in all but the wanted direction of movement, and that isn't possible (I think) with permanent magnets – "Earnshaw's Theorem". All practical mag bearings have an active system that consumes energy to stabilise them, which would probably take a lot more energy than every other part of the clock! Bob Holmstrom in the US reported some experiments using an air bearing which IIRC performed well but of course needs a compressed air supply.

"Secondly, what about engineering a way of physically changing the length of the pendulum to adjust for average swing changes? That would give you accurate time keeping over, say a 24 hr period, rather than trying to correct for every discrete swing?" That is in effect exactly what Robertson did in his clock (see above), using adjustable tension in a spiral spring to apply a variable force acting against gravity, through a cunning linkage. Performance was limited because there was only one 10.00am reference pulse available at the time (1925), by telegraph from Greenwich, and the resulting "sampling rate" of his control loop was too low to follow barometric variations. It would be interesting to recreate his method now we have accurate time from GPS at least every second.

21 December 2022 at 12:26 #625636 John Doe 2Participant@johndoe2Posted by SillyOldDuffer on 20/12/2022 12:33:32

John Doe 2Participant@johndoe2Posted by SillyOldDuffer on 20/12/2022 12:33:32Ah, John beware! You're being sucked into the fascinating world of time-keeping!

My downfall started with an Arduino software project, intended to measure mechanical pendulum clocks as a way of detecting mechanical faults. There are at least two commercial products that do this, but I had in mind a MEW article allowing an amateur clockie to build one. As Grandfather Clocks aren't portable, the idea was that the tester would be plonked next to the pendulum and do it's stuff based on comparing what the pendulum did with an ultra-accurate source, which was GPS. Didn't work out……..

Ah right, I see.

Someone I once knew had a hand-held device to measure the time period of clock pendulums on domestic and church clocks, a device which presumably used an internal crystal oscillator reference, (and which did not need ultra accuracy).

If you are having trouble with GPS satellites, my approach might be to make an external receiving aerial to plug into your GPS device. The aerial could be clipped to a window or placed outside somewhere?

Edited By John Doe 2 on 21/12/2022 12:27:47

21 December 2022 at 13:11 #625646SillyOldDuffer

Moderator@sillyolddufferToday's clock results are encouraging, but there's a new mystery!

The clock was adjusted to count 'nominal' on the previous run's average period, and I reduced the impulse again. The bob now gets kicked 80% of the time, which reduces circular error.

Result – after nearly 42 hours the clock, still uncompensated, is wrong by -0.174s:

ClockRun = 1 day, 17:45:16.825680 (150316.82568s)

ActualRun = 1 day, 17:45:17 (150317.0s)

Difference = -0.174s -0.000116% (-1.2ppm)

Nominal period vs Actual Error=-0.000121%Tick Data

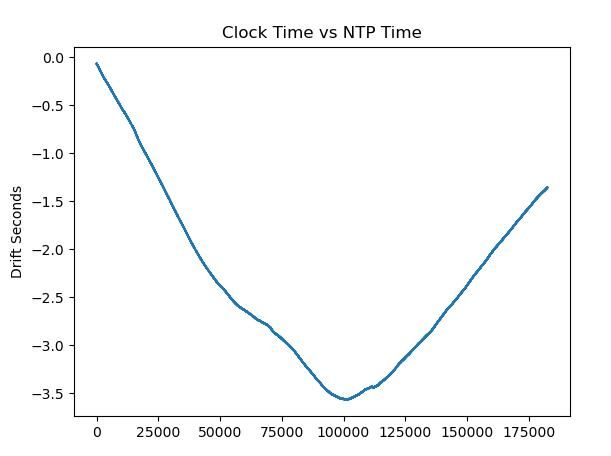

Nominal=823320us Real=0:00:00.823321s Mean=0.823321However, I've added a new graph showing how the clock drifts relative to NTP time, which shows it's wandering!

So, the clock might be only -0.174s slow at the moment, but it slowed steadily for the first 100,000 beats down to -3.5s, not good, and then covered up the error by picking up speed again. Be interesting to see what it does next. I was going to tweak the impulse amplitude threshold, and reduce the impulse slightly, but I won't disturb it.

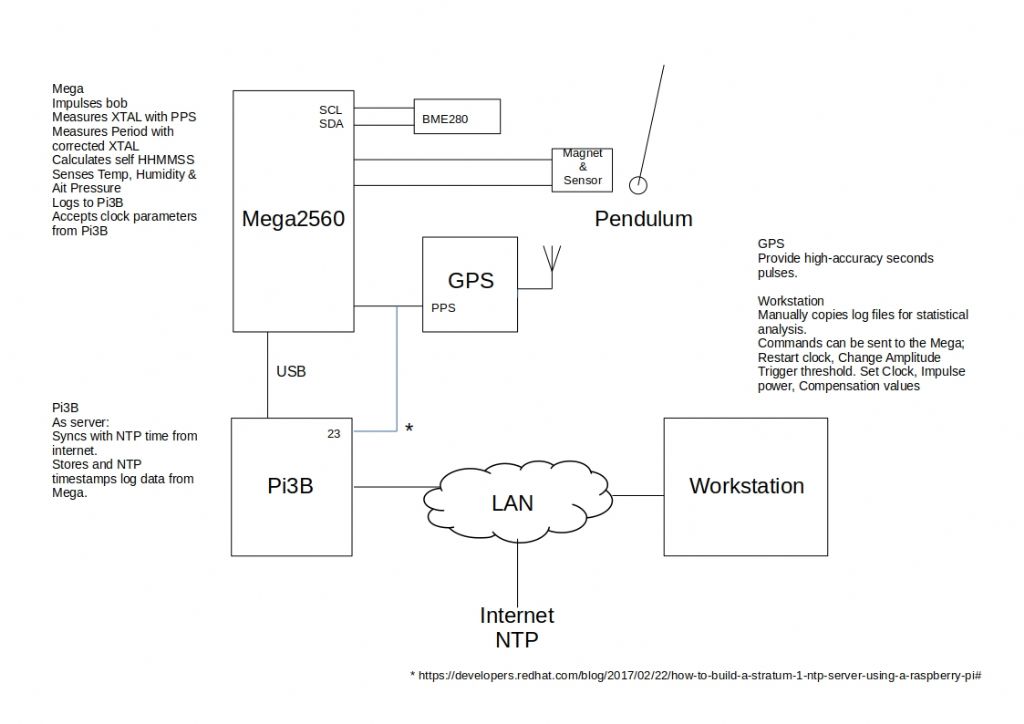

Whilst waiting for components to arrive, I've decided to improve how the clock is measured. At present, period is measured by a hardware counter; it's how many 16MHz crystal pulses are counted between events caused by the bob breaking the IR beam. This OK except Arduino crystals aren't particularly stable. The existing arrangement mixes pendulum temperature effects with temperature effecting the crystal, which could confuse the results.

So I've decided to upgrade from an Arduino Leonardo to an Arduino ATmega 2560. The 2560 has more hardware counters, making it possible to measure the crystal with GPS as well as the pendulum with the crystal. Knowing the crystals actual frequency eliminates temperature effects and significantly improves accuracy of pendulum measurements.

The upgraded set-up will be this:

Another potential improvement is to upgrade the Raspberry Pi3B to be an NTP Stratum 1 server. These use GPS second pulses to correct NTP.

Dave

21 December 2022 at 13:28 #625648Martin Kyte

Participant@martinkyte99762Perhaps a daft question but I suppose you have compared GPS to NTP and established that there is no drift between the two have you.?

regards Martin

21 December 2022 at 14:43 #625653duncan webster 1

Participant@duncanwebster1SOD's latest wheeze just blows my mind!

To return to temperature/density issues, I've remembered that quartz tube has a very low temperature coeff, and found that it is available up to 150mm diameter, so one could isolate a pendulum from ambient variations and still see it working. Slight snag is that it is very expensive.

22 December 2022 at 12:24 #625791Peter Cook 6

Participant@petercook6Dave, for your next project. Now that you have a highly accurate GPS reference signal, and a switching mechanism to deliver a power pulse to the pendulum, rather than complex (PID) math to adjust the pulse timing have you considered using the lack of isochronism in the pendulum as an inherent feedback mechanism.

I assume the pendulum characteristics are such that as the power increases, the amplitude increases, and the rate slows (slightly).

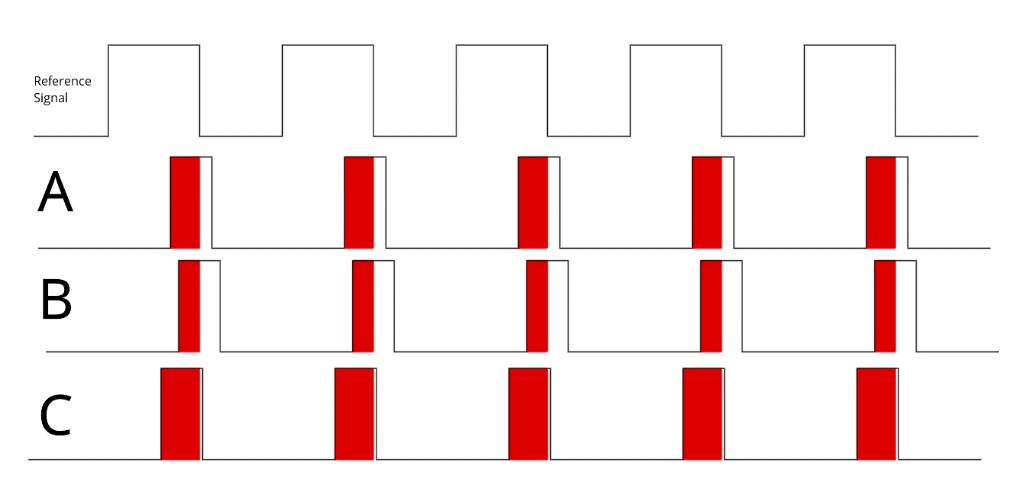

The diagram illustrates the idea in a somewhat exaggerated form. The top line is the highly accurate signal used to deliver a square wave pulse exactly at the pendulum’s ideal rate.

The next three lines show the drive pulses from your sensing/switching mechanism under various scenarios.

A illustrates the ideal position. On each swing, the reference signal goes high before the switching mechanism applies power to the pendulum. The switching mechanism then activates and applies power which is turned off by the reference signal going low. The red area represents the power supplied.

B is the situation when the clock gets a little slow. The pendulum switching will occur slightly later relative to the reference signal. That results in a lower power delivery to the pendulum. Therefore, the amplitude decreases, and the clock speeds up a bit. The feedback continues to increase the rate until we get back to A.

C illustrates the clock gaining slightly. The pendulum switching then occurs slightly earlier relative to the reference signal. The power delivered increases, as does the amplitude and the clock slows down again until position A is re-established.

If it all works as it should, the pendulum rate will inherently lock to the falling edge of the reference signal*.

This is the mechanism, based on an idea from Derek Roberts, which Bryan Mumford developed into his Governor product for Eureka, Bulle and other antique battery clocks. Frank Roetsky makes a similar device.

PS* If the pendulum characteristic is the other way round – increased power increases the rate, and Bryan suggests there are Eurekas that do this, then the mechanism still works except the the pendulum locks to the rising edge of the reference signal.

The method does work well. I have one of Bryan’s units and one of Frank’s on a couple of Eureka clocks and both keep time to within seconds per year.

Edited By Peter Cook 6 on 22/12/2022 12:39:04

22 December 2022 at 12:35 #625794SillyOldDuffer

Moderator@sillyolddufferPosted by Martin Kyte on 21/12/2022 13:28:24:Perhaps a daft question but I suppose you have compared GPS to NTP and established that there is no drift between the two have you.?

regards Martin

I haven't because – assuming I've understood correctly, always a big if – the two are closely related.

Both are based on the World Time Standard, which is the average of a group of high-end Atomic Clocks.

GPS satellites also contain Atomic Clocks, each of which is synchronised by a ground station, with due allowance for transmission and update time.

With an open sky the GPS receiver sees about 20 satellites, of which perhaps 15 provide clear solid signals. Which 15 or so varies with the earths rotation. The receiver gets time signals from all the good satellites it can, and uses a built-in ephemeris to compensate for each satellites space to receive position distance. After earth time is recovered, the time differences to each satellite allow the ground station to calculate it's latitude, longitude and height. Considerable effort is put into GPS time accuracy because positional accuracy depends on it. A GPS receiver with a good view of the sky is the best source of time available, but it works in 1 second increments. GPS second pips are synchronised to earth standard Atomic time within a few nanoseconds.

Network Time Protocol depends on time stamp signals distributed hierarchically across the internet by computers. Network delays vary somewhat and they get worse with distance. Although NTP compensates in various ways, the accuracy at a particular point varies. Worst case, NTP is never more than 100mS out, and most ordinary users are within 10mS. An individual computer won't get the best out of NTP unless set up to do so because the operating system runs on an internal clock, which is only periodically corrected to NTP. Microsoft time is paricularly poor because Windows checks NTP infrequently. Check your computers time here. My Ubuntu machine is 5mS fast at the moment.

The key advantage of NTP is self-correcting accuracy over long periods that just works with no need for special equipment. At worst it's "good enough" for most purposes.

The best way of improving NTP time is to get close to a server connected to a standard Atomic Clock. More practical, and nearly as good, is to set up your own NTP server receiving ordinary network time, and synchronise it to GPS seconds. Synchronising eliminates most of the error caused by network delays.

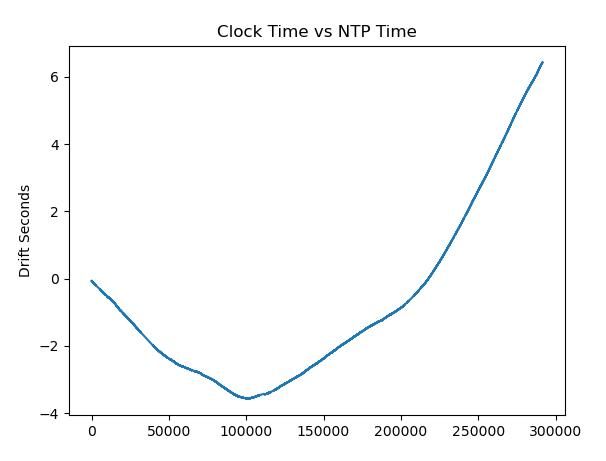

So NTP is always a bit wrong compared with GPS, but they don't drift apart. Unlike my clock, which is up to no good:

Ran slow for 100000 ticks, since when it's been running fast, and the rate is getting worse, cause unknown. I've decided to let it run for a few days to see what it does next in hope of identifying the issue.

Dave

22 December 2022 at 12:40 #625795duncan webster 1

Participant@duncanwebster1Here's a link to the Mumford Governor

I'd better say no more

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Clocks and Scientific Instruments › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Bad design, or am I missing something?

Started by:

half whit in: Beginners questions

- 5

- 7

-

20 July 2025 at 19:16

Julie Ann

Julie Ann

-

Polishing compounds for stainless steel (mild abrasives))

Started by:

Simon Williams 3 in: Beginners questions

- 10

- 11

-

20 July 2025 at 19:00

Michael Gilligan

Michael Gilligan

-

Mistry dividing attachment

1

2

Started by:

Brian Merrifield in: Workshop Tools and Tooling

- 17

- 42

-

20 July 2025 at 18:43

Tony Jeffree

Tony Jeffree

-

Hopeless…Alibre Ass

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 4

- 10

-

20 July 2025 at 17:48

Diogenes

-

Lidl castors

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 3

- 3

-

20 July 2025 at 17:43

Bazyle

Bazyle

-

Epoxy or acid etch primer

Started by:

Michael Callaghan in: Materials

- 1

- 1

-

20 July 2025 at 16:46

Michael Callaghan

-

Diving in to ATC?

Started by:

Steve355 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 4

- 6

-

20 July 2025 at 16:20

Martin Connelly

Martin Connelly

-

What Did You Do Today 2025

1

2

…

8

9

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 33

- 201

-

20 July 2025 at 16:13

JasonB

JasonB

-

Measuring a double Vee lathe bed Vee position

Started by:

Kim Garnett in: General Questions

- 11

- 22

-

20 July 2025 at 15:51

Kim Garnett

-

Please direct me to where I can find an engineer to do some bespoke work

Started by:

srb1 in: Beginners questions

- 6

- 10

-

20 July 2025 at 15:43

Craig Brown

-

Making Unimat DB/SL Steadies

Started by:

Andy Carlson in: Workshop Techniques

- 3

- 4

-

20 July 2025 at 15:35

Andy Carlson

-

Alternative to ARC

Started by:

petro1head in: General Questions

- 4

- 8

-

20 July 2025 at 13:31

JasonB

JasonB

-

My vise isn’t at 90 degrees

Started by:

moonman in: Beginners questions

- 13

- 16

-

20 July 2025 at 13:26

Tony Pratt 1

-

Sat nag

1

2

Started by:

duncan webster 1 in: The Tea Room

- 24

- 50

-

20 July 2025 at 13:18

Nigel Graham 2

-

Which lubricator do I need

Started by:

Michael Callaghan in: Locomotives

- 3

- 5

-

20 July 2025 at 12:45

Michael Callaghan

-

Advice to machine stationary engine base plate

Started by:

Greg H in: General Questions

- 5

- 12

-

20 July 2025 at 11:37

Greg H

-

Model Engine running just off a naked flame

Started by:

Blue Heeler

in: Stationary engines

Blue Heeler

in: Stationary engines

- 3

- 6

-

20 July 2025 at 11:31

David George 1

David George 1

-

Paint stripper does not do what it says on the tin

Started by:

Greensands in: Hints And Tips for model engineers

- 8

- 16

-

20 July 2025 at 11:11

Taf_Pembs

Taf_Pembs

-

Easiest/cheapest source of R8 socket

1

2

Started by:

Beardy Mike in: Workshop Tools and Tooling

- 14

- 27

-

20 July 2025 at 11:01

Tony Pratt 1

-

Hofmann

Started by:

Matt Smith in: General Questions

- 2

- 2

-

20 July 2025 at 10:37

Tony Pratt 1

-

Even the Dealer Didn’t Know!

Started by:

Chris Crew in: The Tea Room

- 15

- 20

-

20 July 2025 at 07:54

Nealeb

-

Boxford paint colour

Started by:

Pete.

in: Workshop Tools and Tooling

Pete.

in: Workshop Tools and Tooling

- 5

- 10

-

20 July 2025 at 01:21

Pete.

Pete.

-

More BBC Masterchef woes…

Started by:

Nigel Bennett

in: The Tea Room

Nigel Bennett

in: The Tea Room

- 6

- 6

-

19 July 2025 at 22:55

Nigel Graham 2

-

Boley 6LZ, new to me

Started by:

Wade Beatty in: Manual machine tools

- 4

- 5

-

19 July 2025 at 22:47

Wade Beatty

-

opposed twin engine calculations

Started by:

bricky in: I/C Engines

- 10

- 16

-

19 July 2025 at 21:50

bricky

-

Bad design, or am I missing something?

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Bad design, or am I missing something?

- Polishing compounds for stainless steel (mild abrasives))

- Mistry dividing attachment

- Hopeless…Alibre Ass

- Lidl castors

- Epoxy or acid etch primer

- Diving in to ATC?

- What Did You Do Today 2025

- Measuring a double Vee lathe bed Vee position

- Please direct me to where I can find an engineer to do some bespoke work