Posted by duncan webster on 08/12/2022 00:52:06:

Now that I've realised that Dave impulses his pendulum at the centre even tho his electromagnet is at the end my reservations have evaporated

The original clock had rather complicated software that fired the pulse 'n' microseconds after the bob broke the beam. As it was fiddly to set-up, I changed the code ages ago to fire the pulse immediately the beam is broken. Sorry if that wasn't made clear at the time.

However, because the beam is offset from the bob the impulse isn't applied conventionally when the bob is travelling at maximum speed, but nor is it applied when the bob is moving very slowly.

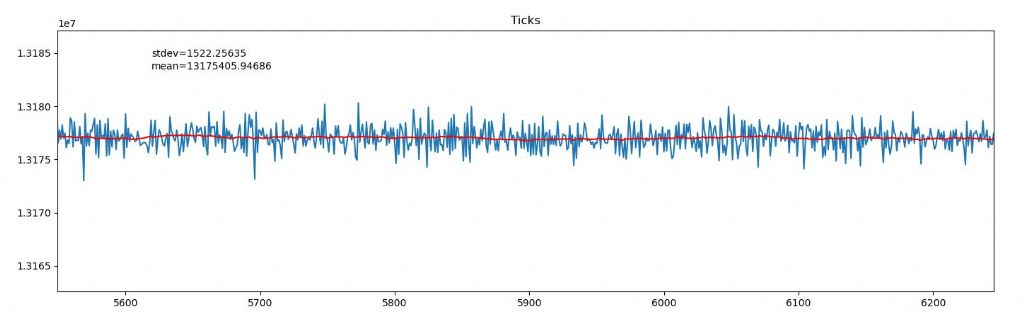

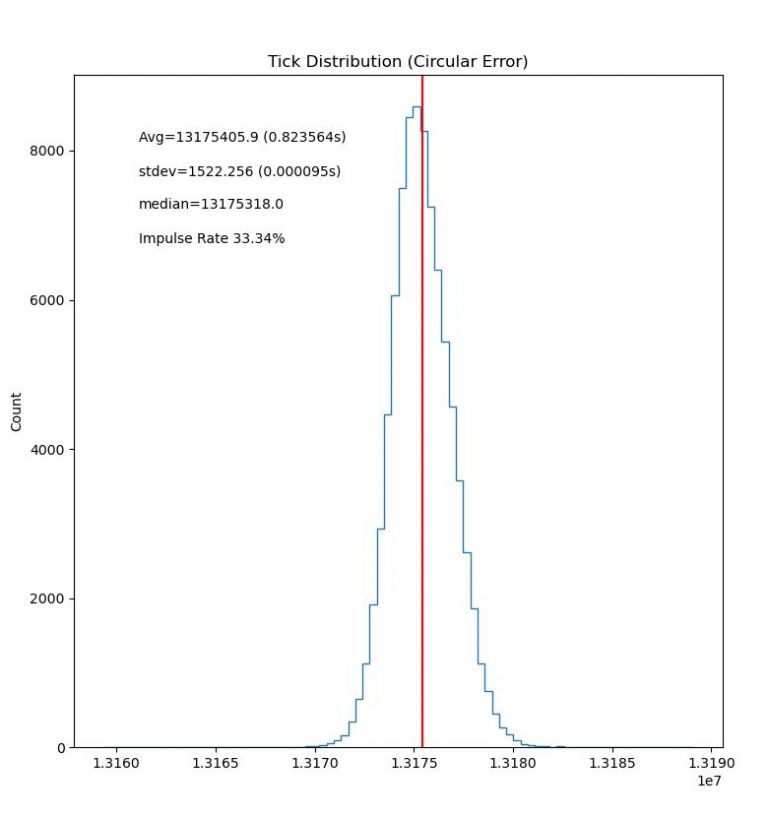

Period is measured as the time between beam breaks.

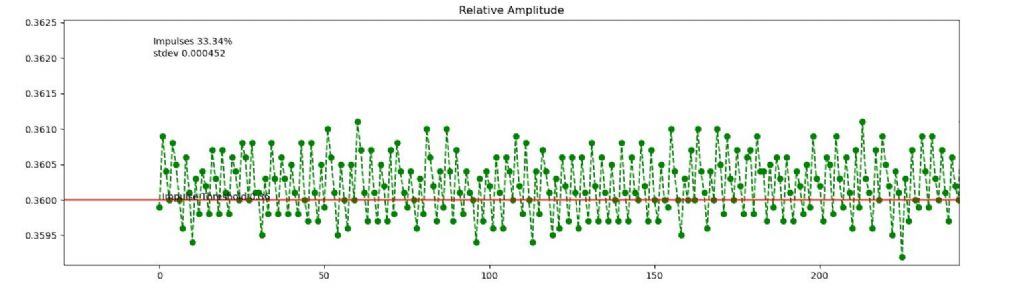

Relative amplitude is measured as the length of time the beam is broken.

The magnet is pulsed when relative amplitude falls below a threshold. At the moment, the threshold is a guess, and the pulse length tweaked manually after inspecting the graphs. I'm trying to find the combination of impulse power and threshold that keeps the pendulum swinging reliably at constant amplitude.

The clock can be told to alter the threshold and pulse length whilst it's running, so it might be possible for the remote program doing the statistics to home in on the combination, if there is one, that produces the most regular pendulum movements.

Mustn't get too carried away. There are mechanical improvements on the to do list. Most urgently I want to make a suspension as described by John, fitted with a longer thinner spring as suggested by Michael.

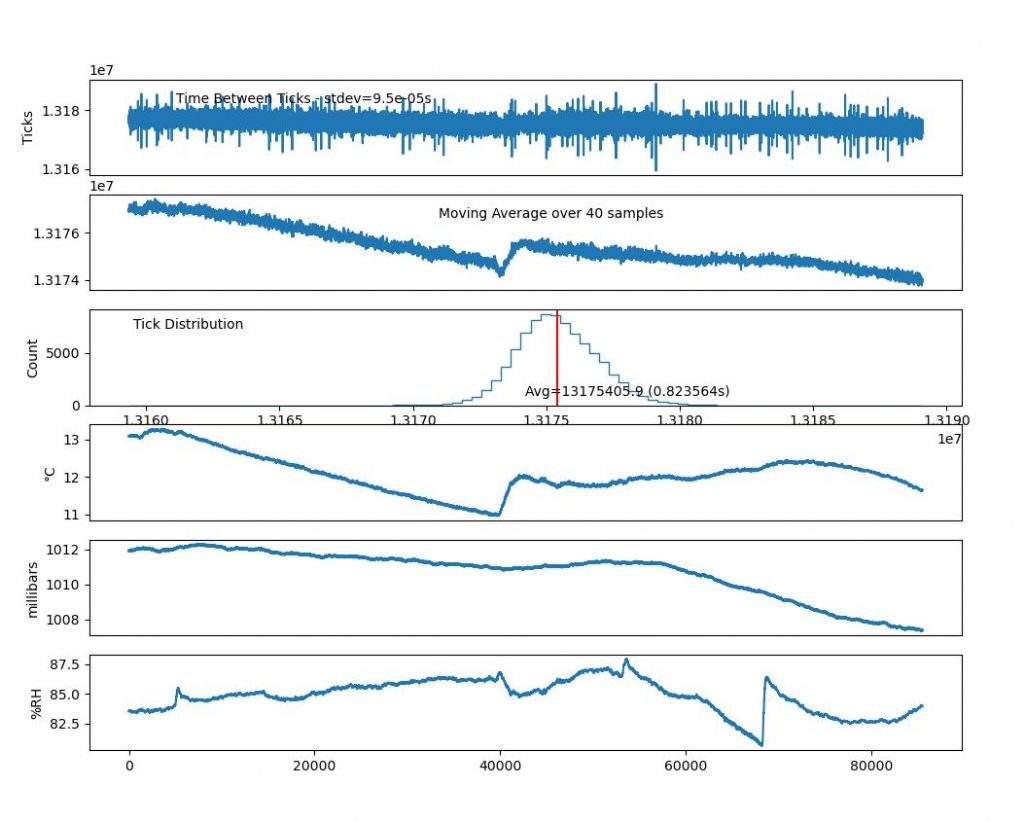

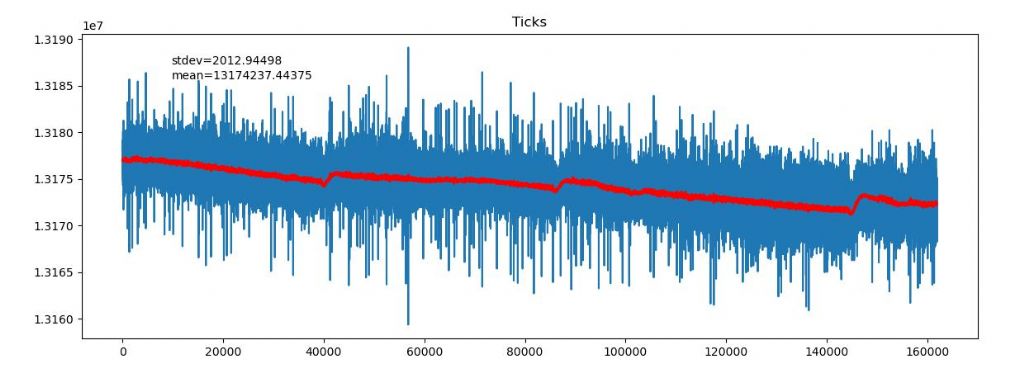

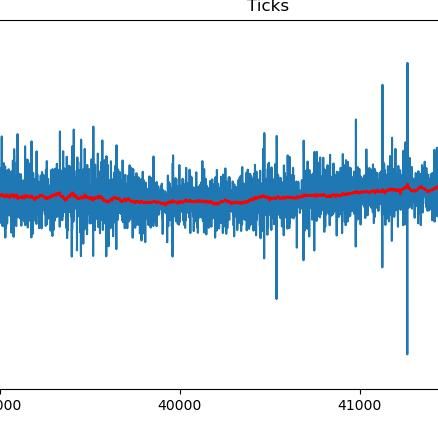

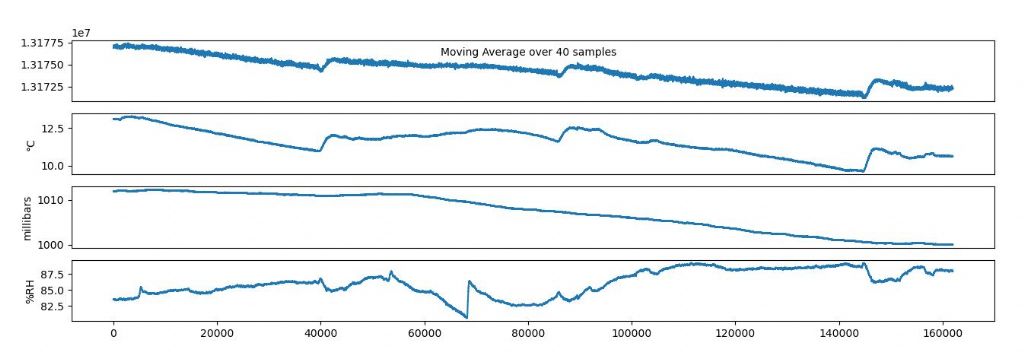

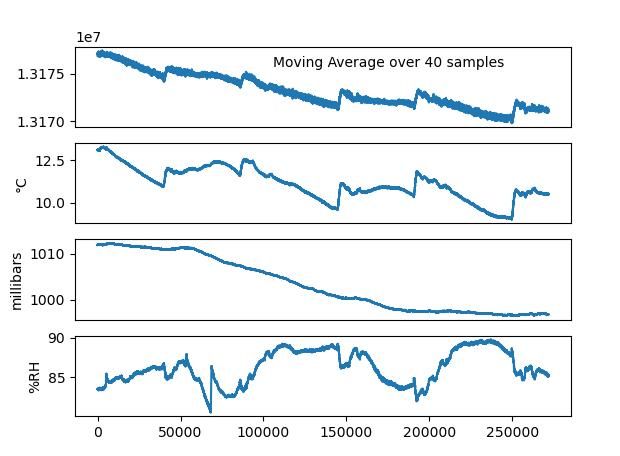

This morning's graph shows the need for temperature compensation: the red line is the moving average, smoothed over 40 samples, and jumps caused by the central heating coming on are obvious.

The graph also shows the pendulum is slowing down overall. I don't know why: the effect doesn't seem to relate to temperature or humidity, but it might be air pressure. Good news if the pendulum is responding to pressure, but I'm not confident my construction is good enough. Other possibilities are the pendulum lengthening due to the super-glue giving way, or the suspension spring pulling out of the clamps.

Dave

duncan webster 1.