Not much progress. Joe's fix worked perfectly but my only 7490 divider chip is dead, probably because I wired it up back to front in an earlier fiasco. Had to order another one, so can't finish the OCXO.

Clock still misbehaving with interesting features. (Yes I know I should get out more!)

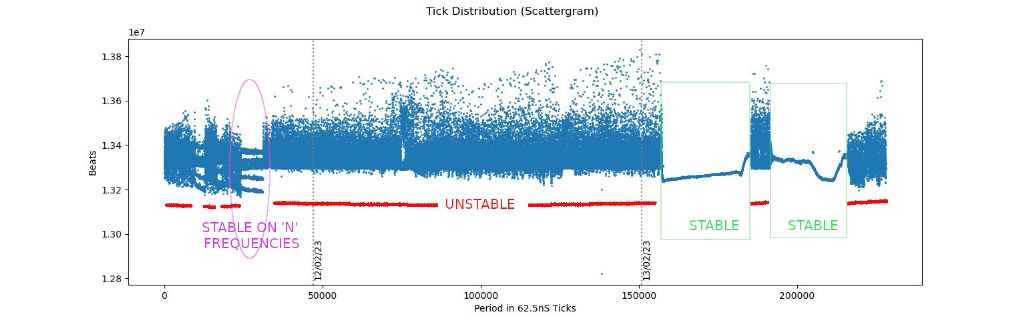

Broadly, depending on impulse power, the pendulum vibrates in at least three different modes, only one of which is wanted – the nice tight line marked STABLE in green above. The pendulum doesn't deviate much, unlike in the red UNSTABLE areas, where the pendulum bounces all over the place.

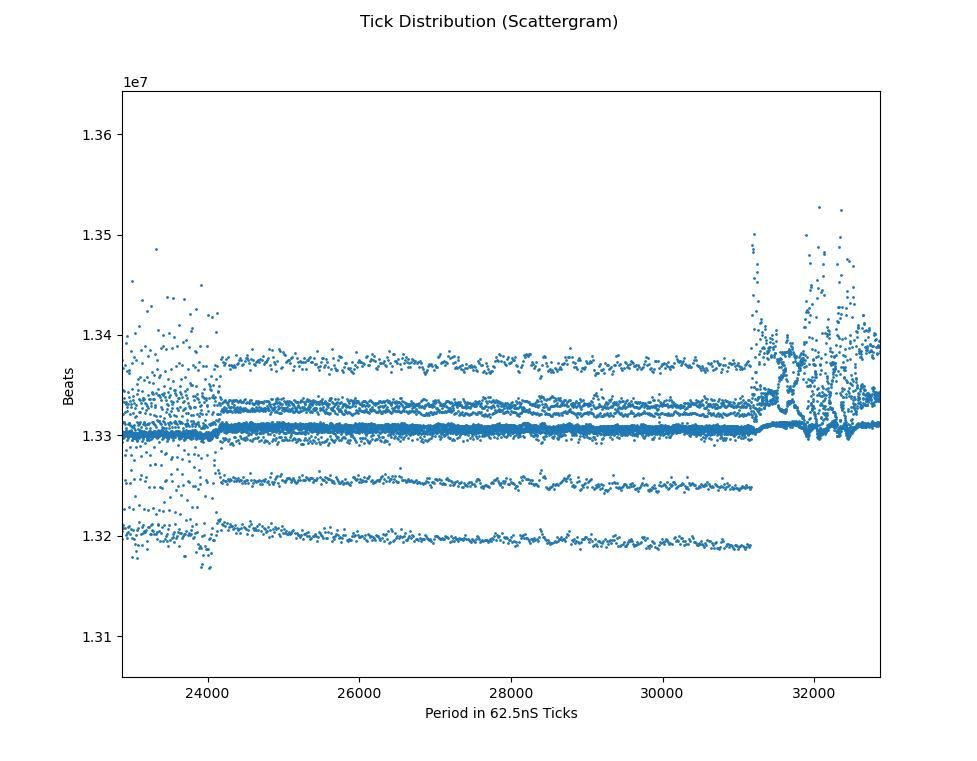

The zone I can't explain is ringed in purple, because it shows the pendulum vibrating in one of several frequencies, making a quantum leap between them. Zooming in, I think I see at least 11 separate traces:

Any ideas what could cause several close but different discrete vibrations. Multi-frequency mode ended abruptly when I reduced the impulse slightly.

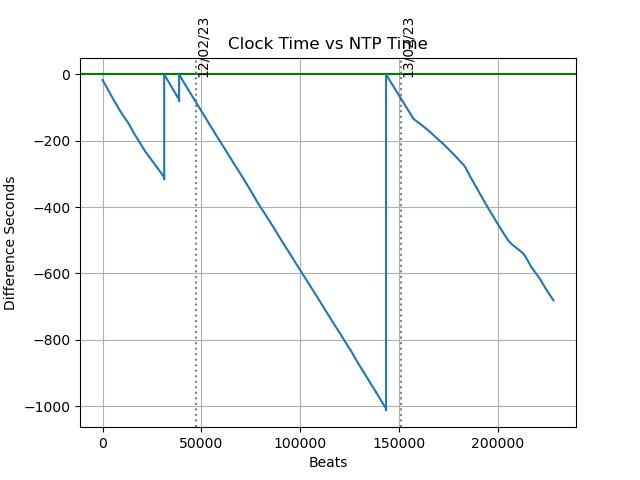

Another quirk is the clock keeps better time when the pendulum is in the unstable zone:

The drift rate on the 12th, when the pendulum was being distinctly over-impulsed, is delightfully constant, meaning it can easily be compensated to stay closely aligned with NTP time. Echoes a comment in Grimthorpe about early clockmakers setting up so the clock dominates the pendulum. In comparison, after the impulse was reduced, causing the pendulum to stabliise, the drift rate on the 13th is kinky! The log shows low impulse power on the 13th starts causing beam break misreads = the pendulum isn't swinging quite far enough.

Confirms the way I modified the sensor in hope of sharpening the beam didn't work, and – woe, woe and thrice woe – the clock is worse than before I 'fixed' it. Oh bum.

Never mind, I've started to plan a major hardware upgrade. I'll share the list later for comment.

Dave

Edited By SillyOldDuffer on 13/02/2023 19:03:22

duncan webster 1.