Back in the late 1980's I adapted the standard Emco boring head design to do facing work as well .

While many of examples of my Boring and Facing head have been made around the world the design did not suit everyone. Some did not like the original large dial used by Emco, not realising this was in fact there to aid balancing.

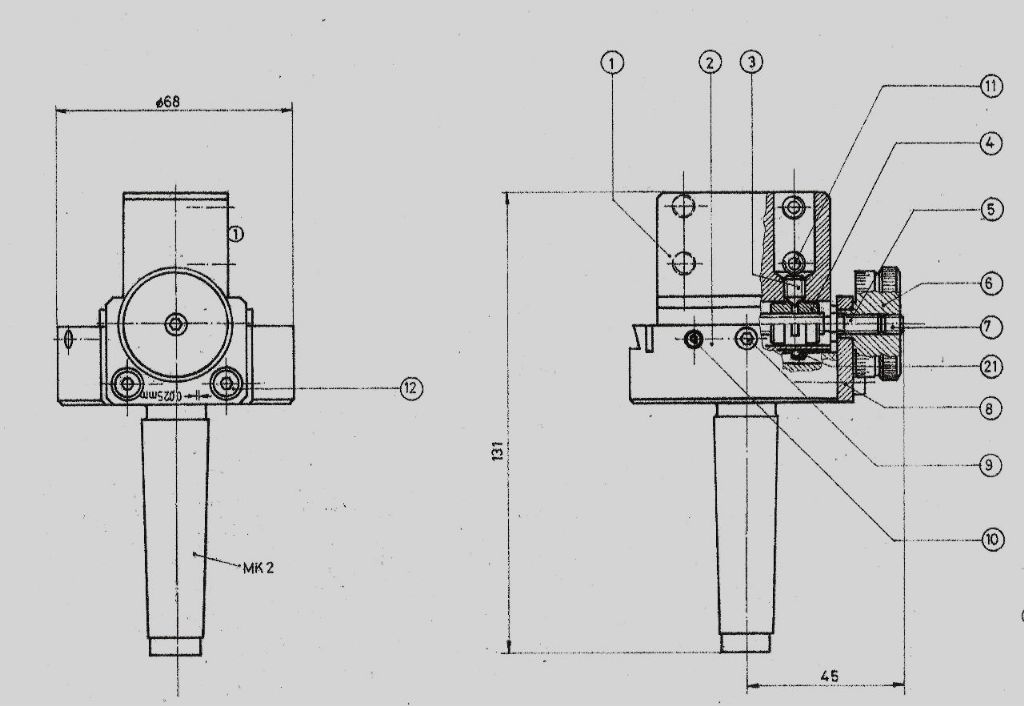

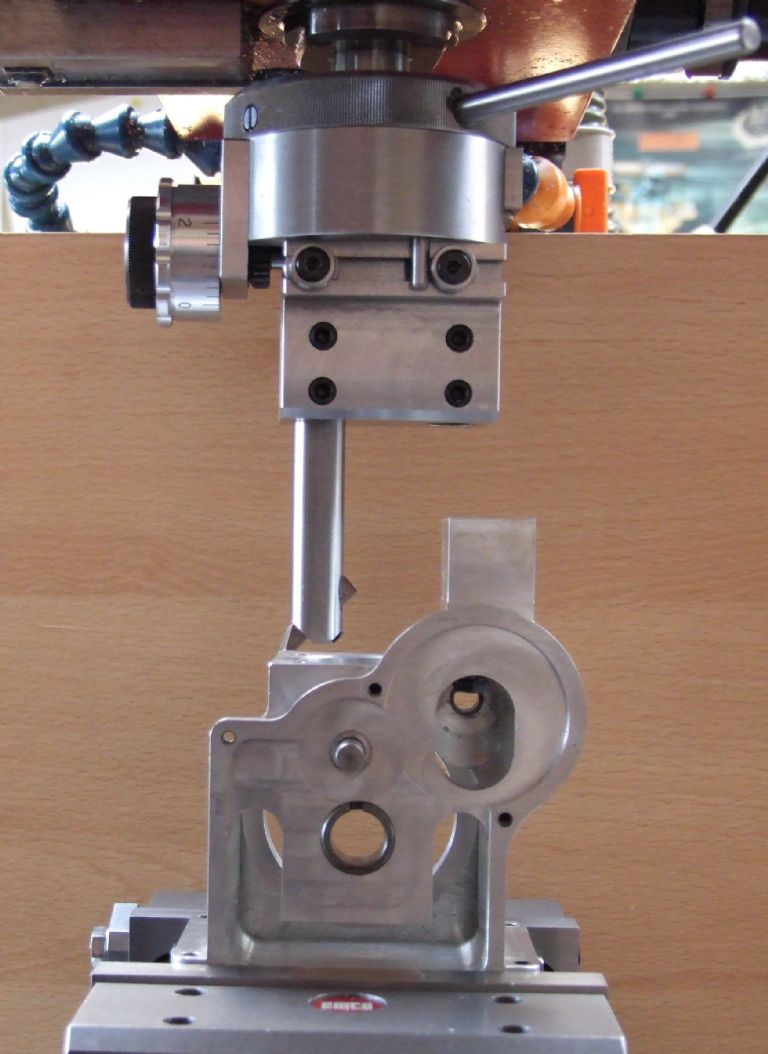

As the original design was an adaptation to meet an the needs of a pending job at the time. I decided to start with a clean sheet of paper and design a boring head which had the dial concentric with the main body. Certain features of the original Emco design have been retained. No point trying to re-invent the wheel.

The New version has a continuous drive to the feedscrew during facing operations un-like my initial design which has an intermittent, 2 speed, bi-directional drive. The New head has a single speed but still feeds in two directions. There is an inbuilt adjustable clutch to cut out the feed when the stops are being used.

The Dial is Zero setting and one complete revolution removes 0.1 mm from the bore. Each numbered division removes 0.01 mm from the bore.

The largish knurled ring on the end is the selector mechanism for the direction of feed.

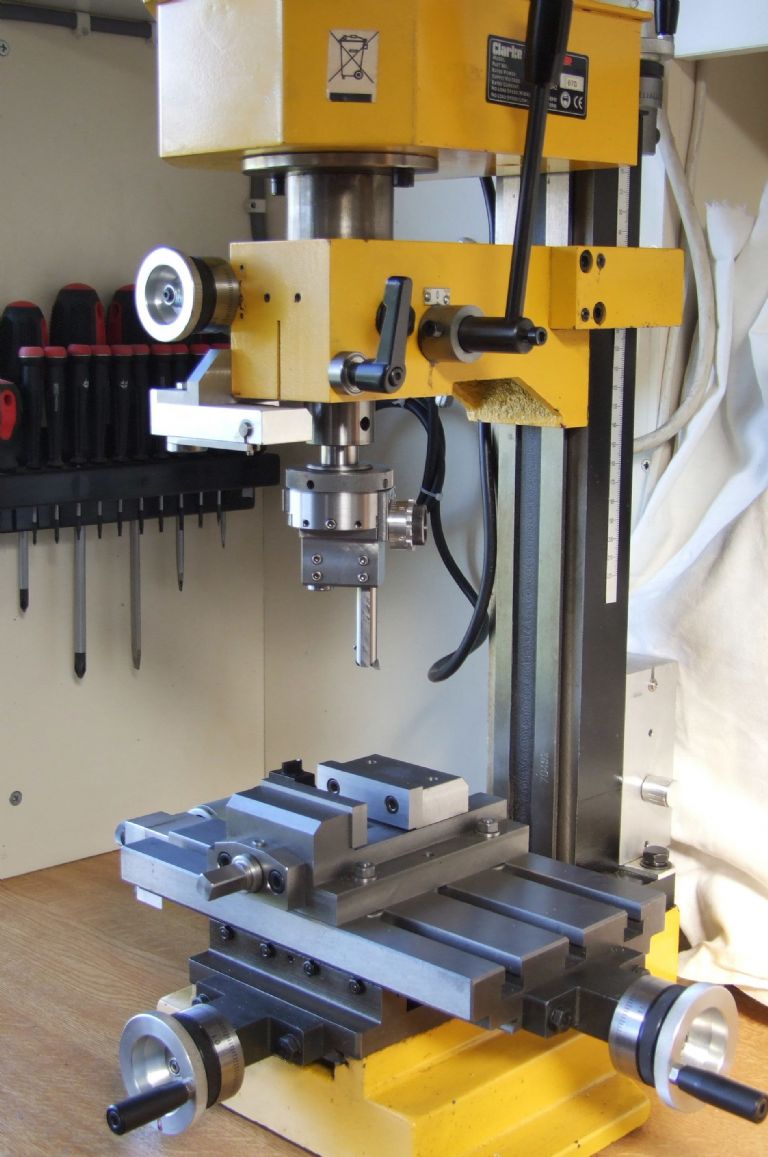

The Mk V head came about after a friend asked me to make him a B&F Head as he could not find one suitable for his new Mill. I must admit I have not seen any to suit this particular mill with a facing capacity. The Mk I being the initial Emco design.

More details of the evolution to follow,

Regards

Gray,

John Hinkley.

John Hinkley.