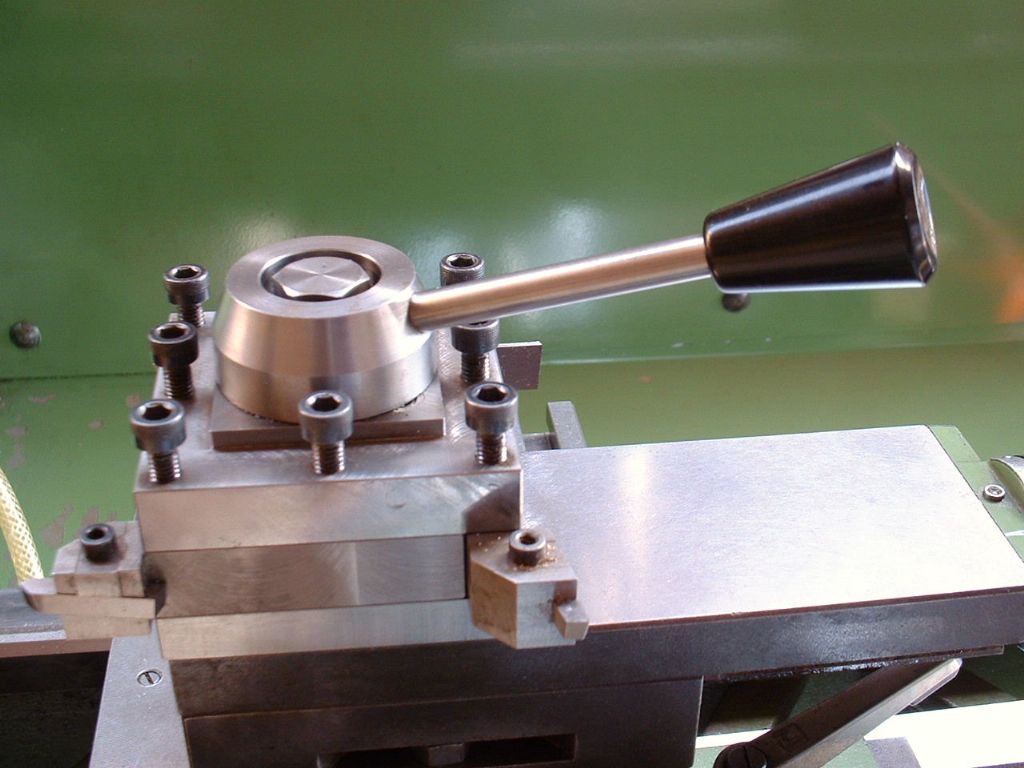

Those members who have followed my work over the years know I favour the 4 Tool Turret. While I know this is not everyone's cup of tea it does have its place in machine tool history.

A recent problem with my adaptation of George Thomas's Turret design was the tendency for the turret to stick firmly on the cone. Rather than just flick the turret round with the index finger of my left hand. I had to grasp the turret with my hand to free it.

Cutting oil was migrating along the bottom face of the turret and then up the cone taper. That plus a "close fitting" cone which has got better over the years required a solution.

George said in his article originally that he would have liked to make the turret self indexing, similar to the "Herbert Combination Turret lathes at the works". As my thought began to work out what to do as regards the sticking of my turret my mind went back to the above statement.

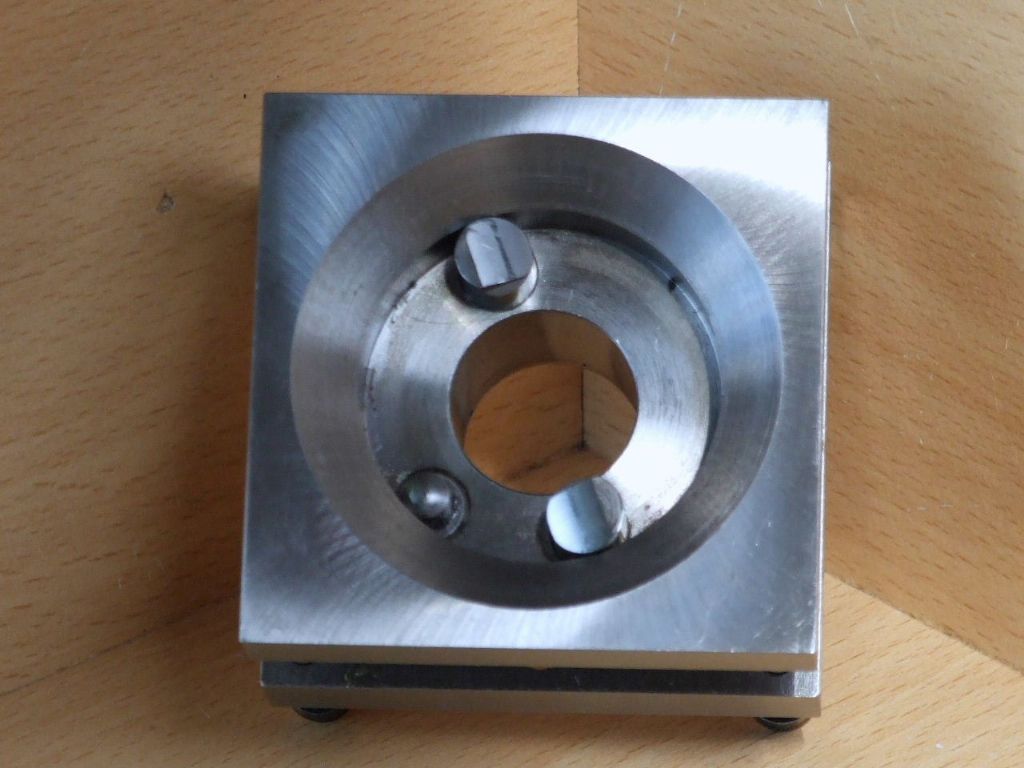

Two spring loaded urges pressing on the ratchet face would take care of the sticking problem. If these urges were so placed they could be used to re-index the turret as it moved around the central post. The angular faces sliding down the ratchet faces so urging the turret towards the indexing pin with a constant force.

The only problem now was to move the turret as the locking lever was operated. This came in the form of a one-way clutch, which came direct from the pages of MEW.

A clutch is preferable to a ratchet system, especially when the turret is being swung through an odd angle. Such as it would be when screw cutting for instance. Always assuming the reader uses this method of screwcutting, not everybody does. It allows for the turret to be set at any position and not dependent on any ratchet position.

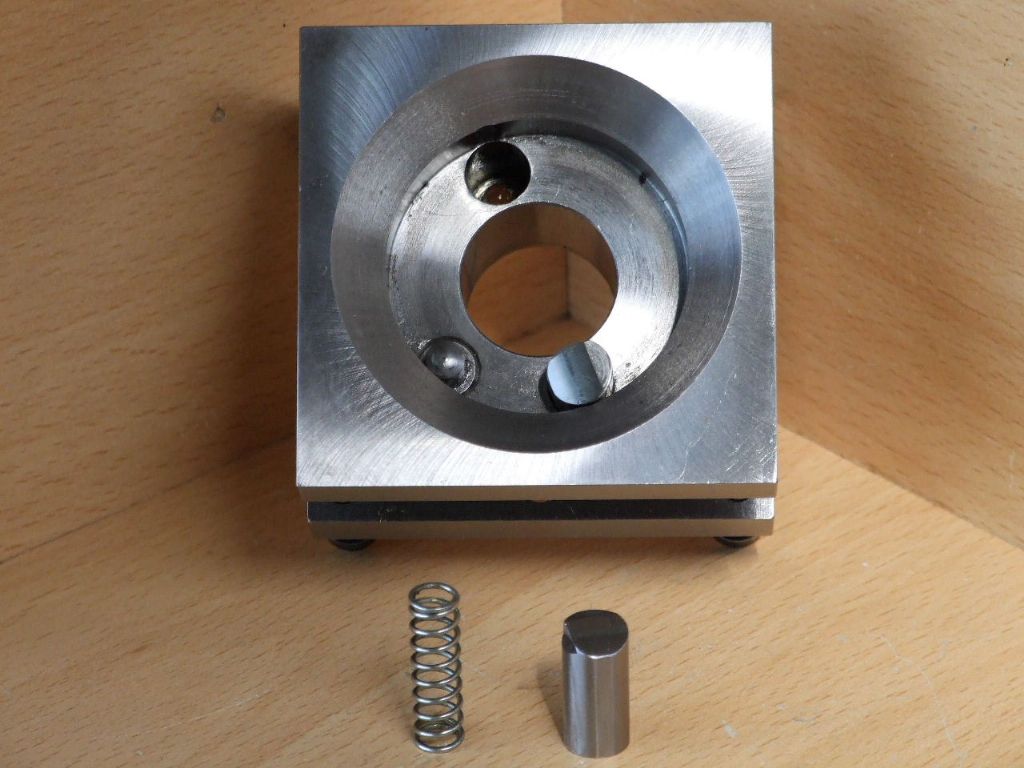

Below is my original design adaptation for comparison.

The only external difference is the additional flanged plate held on by two M4 capscrews. This also stops small particles of swarf migrating into the needle roller race that I use in my adaptation.

I have been using this set-up now for a few months and it has come up to my expectations. All the parts are mild steel, with exception of the curved spring loaded cams and the rollers in the clutch which are silver steel. If wear does become a problem then I shall think again about my material choice, but for the time being I am prepared to run with this.

I have schemed out an adaptation that could be fitted to George's original design. If there is enough interest shown, I am prepared to write this design up and incorporate the modification to GHT's original.

Regards

Gray,

Graham Meek.