Holding an ER collet chuck, with a plain shank in another ER collet chuck, will not only have the disadvantage of not being able to pass material through into the spindle, but possibly reduce the concentricity, by virtue of the fact that the shank and the taper for the collets will have a tolerance on the concentricity between the two.

Sod's law says that the tolerances on the original collet and chuck will be increased by the eccenticities coinciding and whatever the eccentricity is between the shank and the collet taper will add to that of the original chuck!

Daft suggestion, which will still, unavoidably, introduce extra tolerances / eccentricities.

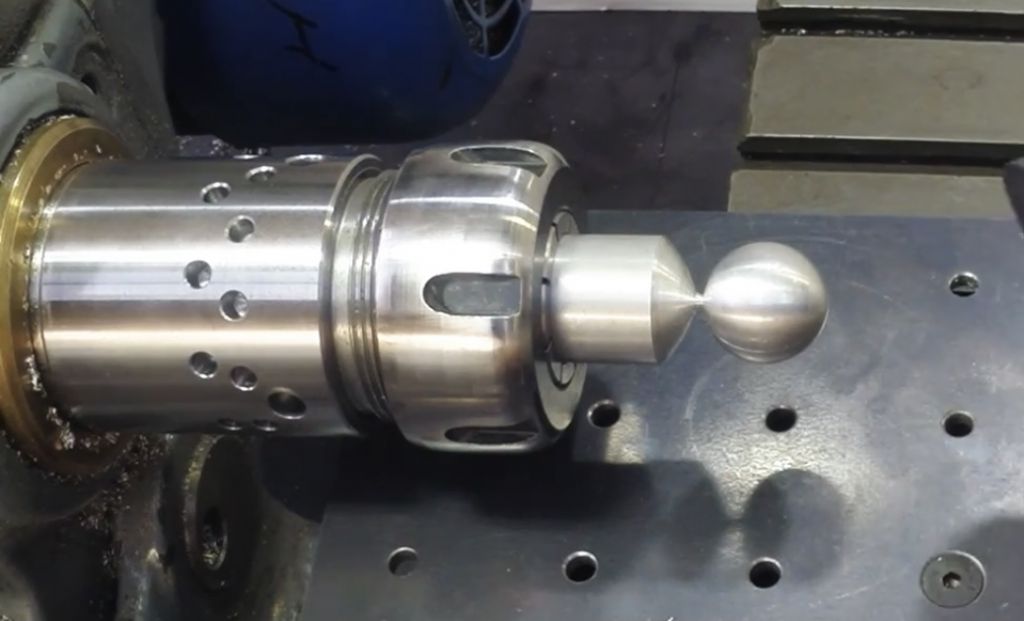

Turn up a taper to sut the collet chuck (16 degrees overall) on a hollow extension, and then use an ER nut to clamp it in place.

The outer end of the extension will need to be screw cut and internally tapered to suit the collets and the clamp nut. without disturbing the "dummy" collet and extension assembly, to maximise concentricty.

The difficulty is going to be the means of engaging the nut when the time comes to release the "dummy taper" extension from the original collet chuck.

Maybe a two piece extension, with a groove, into which the nut can be engaged, before the outer part is fitted into position.

The two parts need to be such that when assembled, there is a groove into which the clamp nut has already been engaged.

The outer taper bore and thread need to be machined after the the outer section has been fitted to the "Dummy" collet, inner part.. (Screwed / Loctited / Heat & Freeze )

Since the extension will be hollow, it will be possible to pass longer workpieces into the lathe spindle.

But repeateability will remain to be seen. It may be necessary to mark both collet chuck and extension so that they are always assembled in the same realtive position.

The other drisadvantage will be that the extension will have a smaller bore than the original collet chuck. So an ER 32 chuck may well end up with ER25 collets on the end of the extension. But 16 mm for long pieces will be better than no through capacity.

HTH

Howard

Graham Stoppani.

Graham Stoppani.