On

31 October 2024 at 18:48 JasonB Said:

We have different ideas of Short.

But I did the same test again. This time a 10mm dia cutter inserted 10mm into an ER32 Collet. Hand tight I could just get a 9.5mm drill shank in the back end. Nipped up with a spanner it went down to 9.3mm so hardly parallel!

I’m not sure what the rest of you make or not but I often hold items by less than 3mm quite often 1mm is all I have to hold. Provided you don’t go silly with stickout or greedy cuts there is little problem with a 5C collet but I would not do it with my various size ER collets without plugging the other end. After all 5C are meant for holding WORK.

Here is an example, Cylinder cover for a 12mm bore engine. 1mm long spigot on the inside and a curved shape spigot on the other.

Hold by the stock dia, turn, face, drill, ream and turn the inner spigot so all concentric.

Cut it off the bar, hold by the 12mm dia x 1mm long spigot to turn the other side

Something a bit longer for the current Clarkson build. 1.6mm dia, 2mm of M1.6 thread, dome the end. Easy enough holding the stock to do that. Now cut off and face the other end back to 4.5mm overall length and dome the end. Move from 5C lathe chuck to 5C collet block to cut the slot 0.5 x 0.5.

Or want to hold a larger cylinder cover for drilling stud PCD. Hold by 0.75mm long spigot and drill. Take care on breakthrough as there is not much room to spare, and don’t lean on the drill too hard. Turning was done with soft jaws

On

31 October 2024 at 18:48 JasonB Said:

We have different ideas of Short.

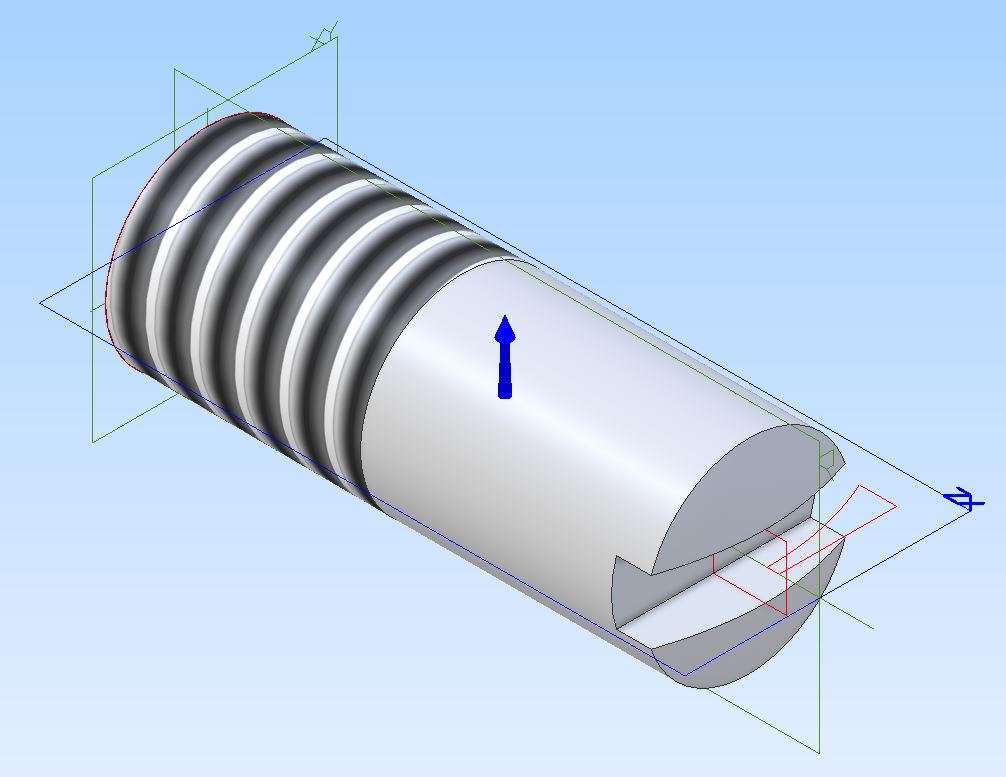

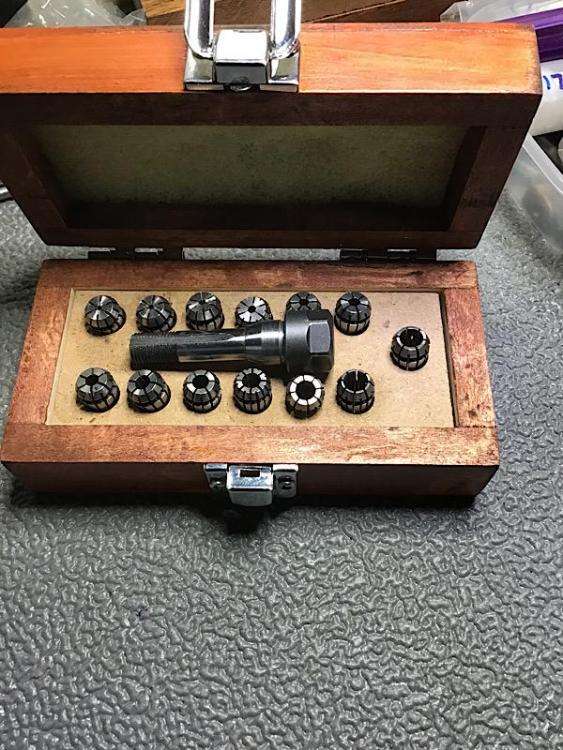

But I did the same test again. This time a 10mm dia cutter inserted 10mm into an ER32 Collet. Hand tight I could just get a 9.5mm drill shank in the back end. Nipped up with a spanner it went down to 9.3mm so hardly parallel!

I’m not sure what the rest of you make or not but I often hold items by less than 3mm quite often 1mm is all I have to hold. Provided you don’t go silly with stickout or greedy cuts there is little problem with a 5C collet but I would not do it with my various size ER collets without plugging the other end. After all 5C are meant for holding WORK.

Here is an example, Cylinder cover for a 12mm bore engine. 1mm long spigot on the inside and a curved shape spigot on the other.

Hold by the stock dia, turn, face, drill, ream and turn the inner spigot so all concentric.

Cut it off the bar, hold by the 12mm dia x 1mm long spigot to turn the other side

Something a bit longer for the current Clarkson build. 1.6mm dia, 2mm of M1.6 thread, dome the end. Easy enough holding the stock to do that. Now cut off and face the other end back to 4.5mm overall length and dome the end. Move from 5C lathe chuck to 5C collet block to cut the slot 0.5 x 0.5.

Or want to hold a larger cylinder cover for drilling stud PCD. Hold by 0.75mm long spigot and drill. Take care on breakthrough as there is not much room to spare, and don’t lean on the drill too hard. Turning was done with soft jaws

Yes, that cover is the sort of part I often hold in my ER chuck without plugging the other end and never had a problem. I have repeated your test with a 12 mm cutter inserted in a 12 – 11 mm collet and yes, the back end closes down, but I only measured about 0.2 mm of closure (perhaps my arthritic hands are getting weak).

My question remains, what is causing the back end to close up? There is no contact at the back between the collet and the socket so the force must come from elswhere.

HYPOTHESIS: Perhaps the problem is caused by the short front taper of the collet not matching that of the nut. If the initial contact between the collet front taper and the nut taper occurs at the back end of that short taper, then as the chuck is tightened the front of the collet will be pushed out creating a levering effect.

Any other suggestions?

Russell

Michael Gilligan.

Michael Gilligan.