Posted by John Haine on 04/03/2021 21:34:30:

I keep on banging this drum, but with a small milling machine you can easily run out of headroom once you put a vice on the table and a chuck in the spindle. Since the range of cutter sizes is quite limited, say 3 or 4 of both metric and imperial, a good option may be to use MT3 collets direct in the taper, once for each size. Not only will you get more headroom but better rigidity.

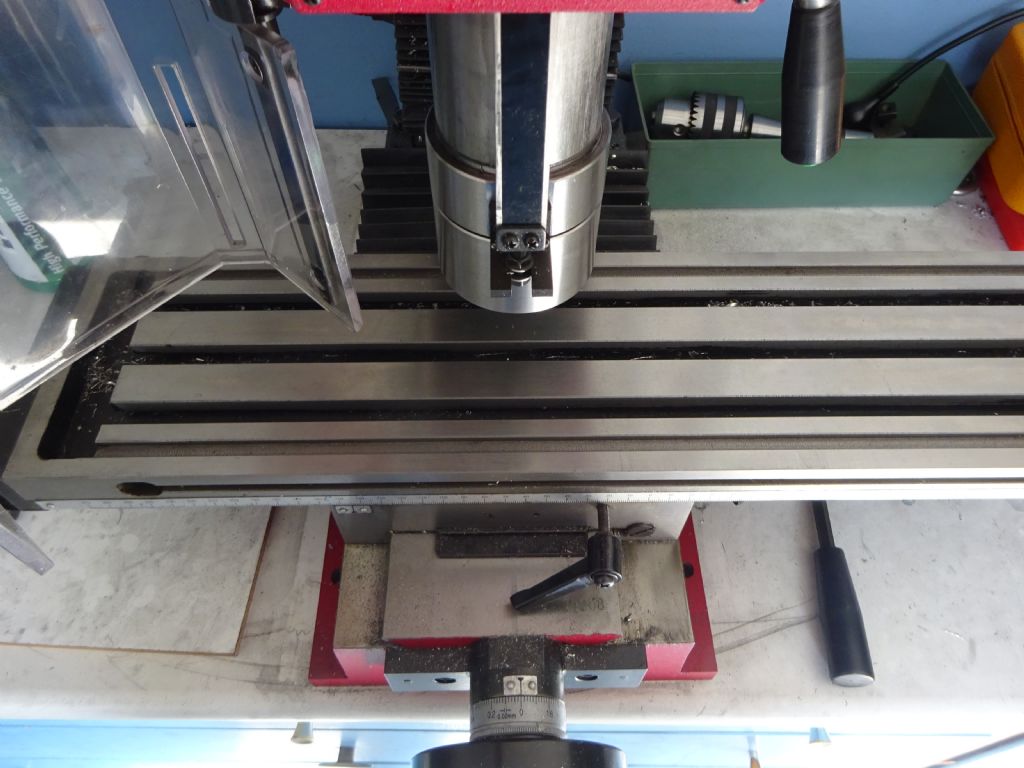

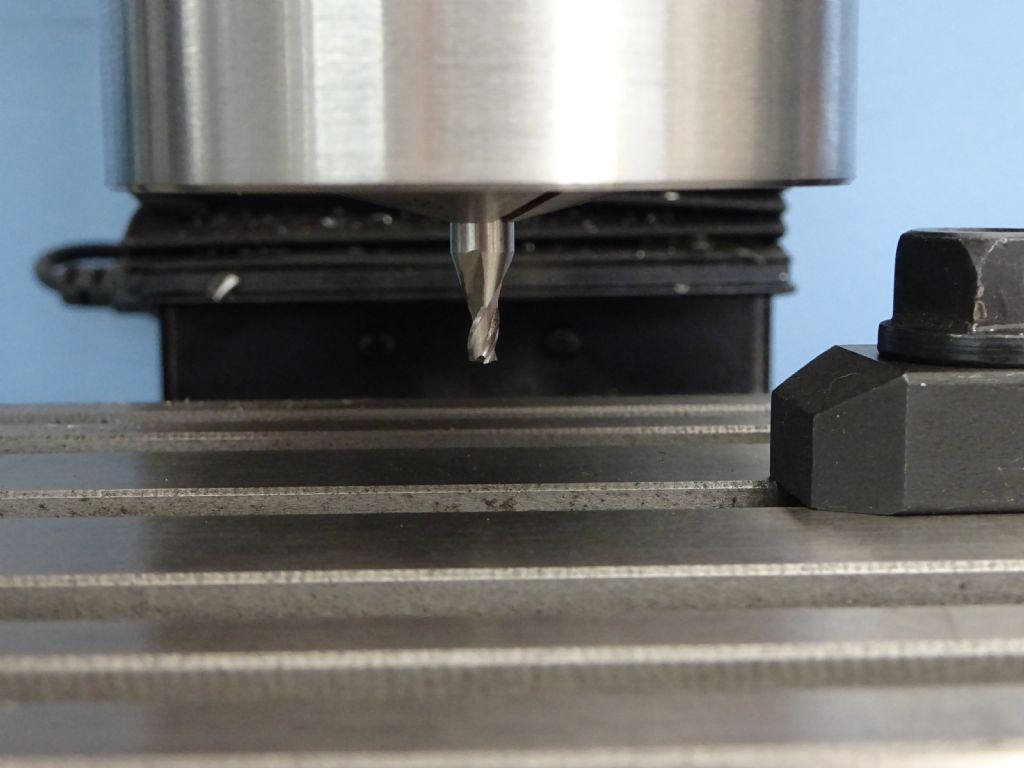

As Vic says you can fet other issues if you just use MT or R8 collets, Yes they are handy when you need the head room but depending on your mill's spindle nose can be even worse than a large ER32 or even ER40 nut as vision is poor and that is more of an issue if using handwheels than a DRO or CNC plus any clamps get in the way. Also note in the photo the quill has had to be fully extended to get the cutter below the bottom of the guard which does nothing to help rigidity and eating up any savings in head room.

Myself I generally use ER32 on the manual X3 mill which includes a good 90% of my drilling as well as milling, I have finger collets that get used for when I need the height or for one particular shank cutter and also have a couple of sidelocks but have not used then in the 6months or so since I bought them. Also got an ER16 for Xmas but have not used it yet mainly as collets are in the other workshop and can't be bothered to go and get them but would if the ER16 was really needed due to access.

the SX2.7 I tend to use the ER25 99% of the time and have used sidelocks in anger on that, don't think the finger collets have been used.

KX3 is almost all ER16 as I don't use large cutters on that and the smaller nut makes it easier to get in and clear swarf.

Having 5C on the lathe I'm not so worried about workholding on that but do have ER32 & 25 blocks

So really there is no ideal one item does it all and what suits one person uses and one particular machine may not suit another but my opinion is ER will do most things from the start and then add as and when needed

Edited By JasonB on 05/03/2021 08:27:44

Howard Lewis.

and 28.5mm (1 1/8&rdquo

and 28.5mm (1 1/8&rdquo