As an accomplished purveyor of red herrings, will add my four penn'orth.

Evening classes are currently like hen's teeth, so joining a Model Engineering Society is a very good idea, ditto, keeping a close eye on this Forum. There is always something to learn.

As an Apprentice, all our courses, (Turning, Milling, Grinding, Fitting ) started with Safety. This is important, but very few Model Engineers, demonstrating or advising hands on practice will mention it. Just taken as read that all know how keep safe.

WRONG! If you have ever had a drill grab, when using a low powered pistol drill, you start, or should, learn to respect motorised tools.

It was many years after leaving the First Year Training school, before I next touched a machine tool (Saw quite a lot in the interim, though! ) before I finally achieved an ambition and owned a well used lathe.

Then the learning really started.

As confidence grew, so did the range of tasks undertaken. At the start, never imagined that I would ever screwcut, or cut gears. But I do, not very expertly, but they do the job, which is all that I ask.

But, as they say in agricultural circles, "Make haste, slowly"

Don't exceed your capabilities, by too much. For that way lies disillusionment, and possibly damage to machine, yourself or others. Stretching the boundaries A LITTLE, is the way to learn. Even if only that it was the wrong way to go about it!

Definitely buy and read books, by such as L H Sparey, Ian Bradley, G H Thomas, Stan Bray, David Clark, Dave Fenner, Harold Hall, or Neil Wyatt. You can profit from their experience.

Having joined a M E Society, don't be afraid to ask questions, for help and advice.if some kind member/s will help to teach you, Ignore those who ridicule you. They have forgotten that once they did not know!

Beware! You may learn some of their bad habits! Also, some techniques may not necessarily read directly across from one machine to another in detail.

And we will all try to teach you to ride our particular hobby horses.

Howard

.

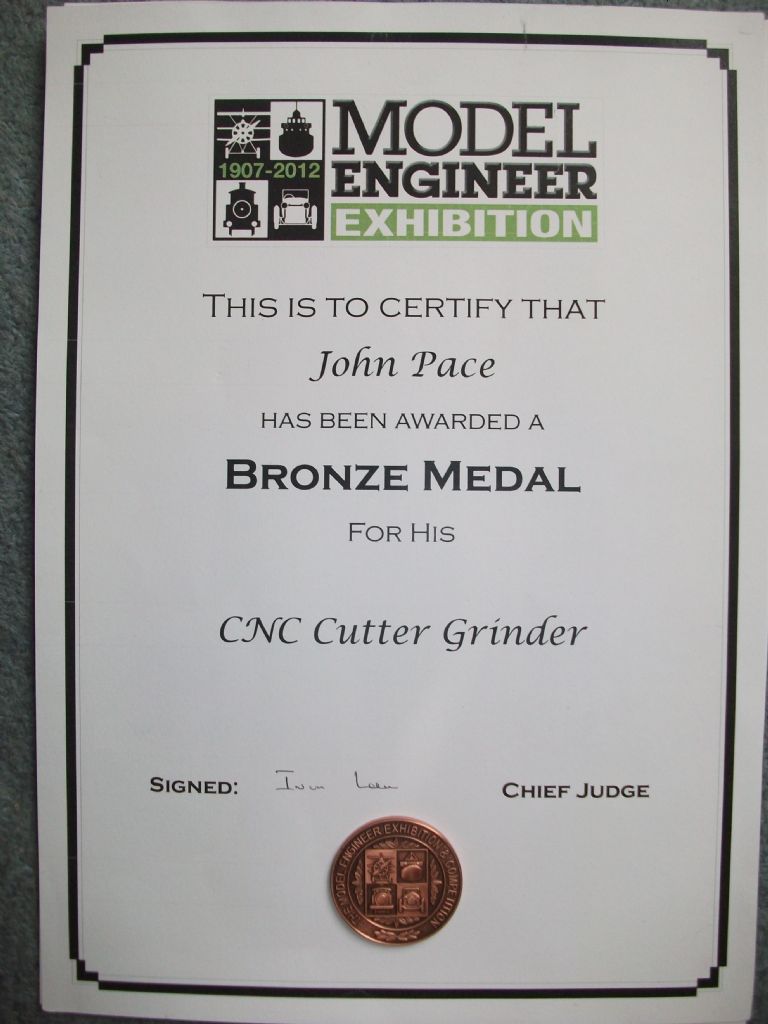

David-Clark 1.