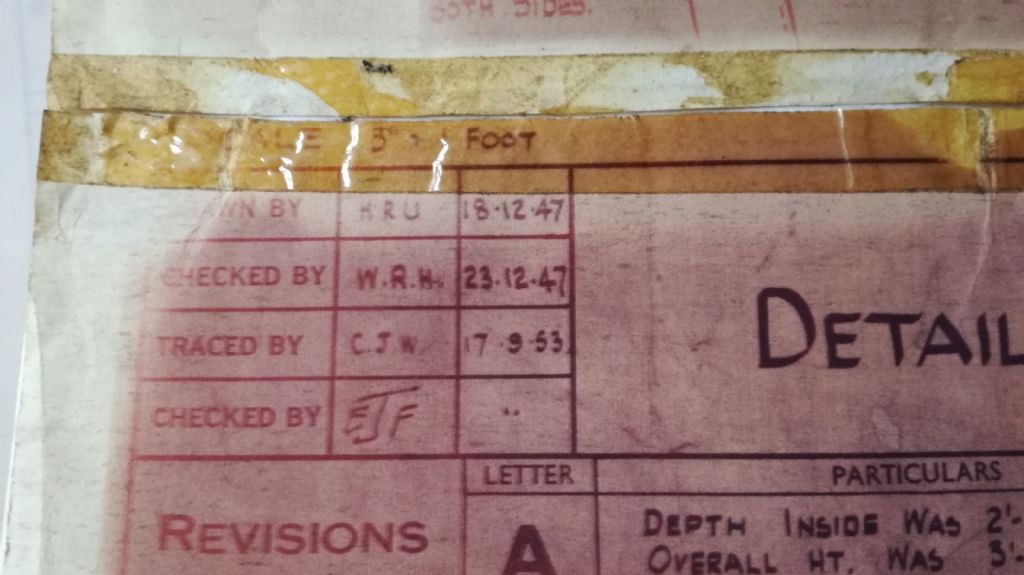

Vellum, as used on this side of the pond, is paper made from cotton fibers.

It can still be purchased in all sized including rolls for a plotter, and it is premium paper with a premium price.

It is similar to what money is made of, ie: you can get it wet and it will not disentigrate or deform, and will not be harmed by water if you dry it carefully.

Less expensive paper is made from wood fiber, and it will degrade and deform if exposed to water.

The vellum drafting paper is very tough, and can be purchased a little thicker than standard paper if desired.

You can erase pencil many times from vellum, and sometimes ink a few times from it, without abrading a hole in the paper.

We used vellum exclusively to create engineering drawings, both from an initial durability standpoint, and also from a long term storage standpoint. Vellum is great to work with. I still have some of my vellum drawings from my later drafting classes in college.

The next step in the drawing elovlution I think was mylar, and we used double-side-matte finish, so it could be drawn on both sides (we sometimes did that in the day).

Mylar will last about forever, and my large clients still require all my final designs to be plotted on it.

36" x 50 yard mylar runs almost $400.00 per roll, so for me that is 75 plots, at $5.33 US per sheet.

I have projects with 100 sheets, so one must not forget to include the printing costs in the initial proposal.

In the old days of manual drafting, you had to be very careful to not burn through the top matte on mylar with the electric eraser, else you would have a bright spot where only a permanent marker could be used.

Mylar uses a special plastic eraser material.

Then came the "slick" system, which was clear plastic sheets with a photo sensitive coating.

You could create multiple copies of an architectural base plan, and distribute those drawings to all the various engineering disciplines.

A clean mylar sheet was placed over the slick, and then each discipline drew their own material on their own mylar sheet. When the architectural floorplan changed, one only had to pull out the slick, and insert a new slick.

Registration was accomplished using a "pin bar", which was a thin strip of stainless steel, about 36" long, with short pins protruding up every six inches or so. All of the mylar sheets and the slicks had holes across the top.

Every now and then the slick registration would get off, and would cause terrible problems.

With slicks, you could also stack multiple drawings on top of each other, and print them on a vacuum printer, which was photo sensitive based printing. This could be useful for cross-discipline coordination.

The original "blueline" prints (copies of vellum drawings) had a blue background with white lines.

When I started, they were using ammonia-developed bluelines to make copies, and the lines were blue, with a white background. The old blue background bluelines are very difficlult to read in my opinion.

With the advent of modern 2D CAD programs, which I started using in the early 1990's, we used virtual layers instead of physical slick/drawing layers.

2D CAD revolutionized how drawings were produced in the engineering world, but there were still many errors due to the fact that each view was drawn separate from all the other views.

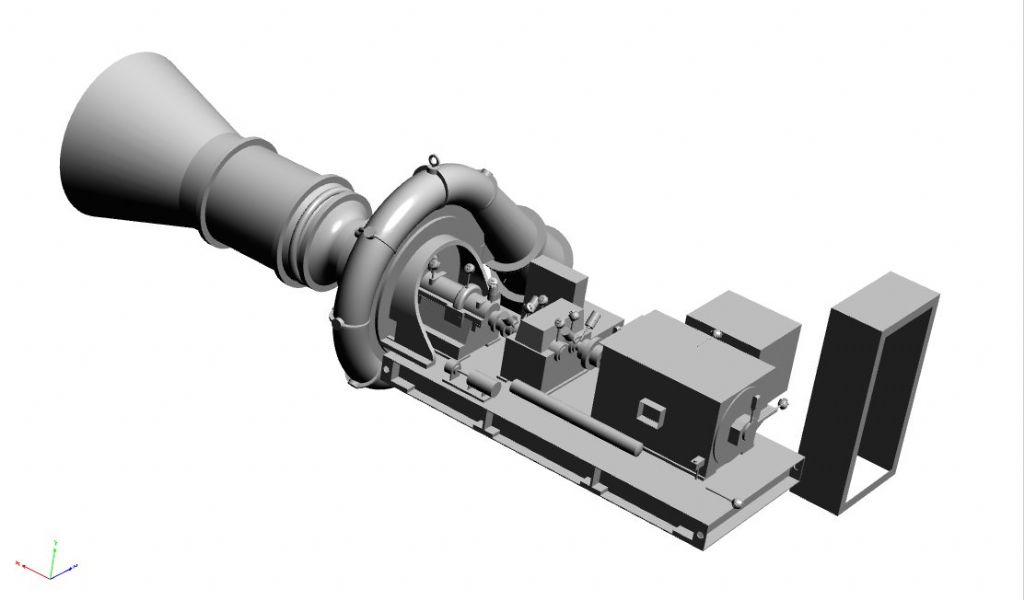

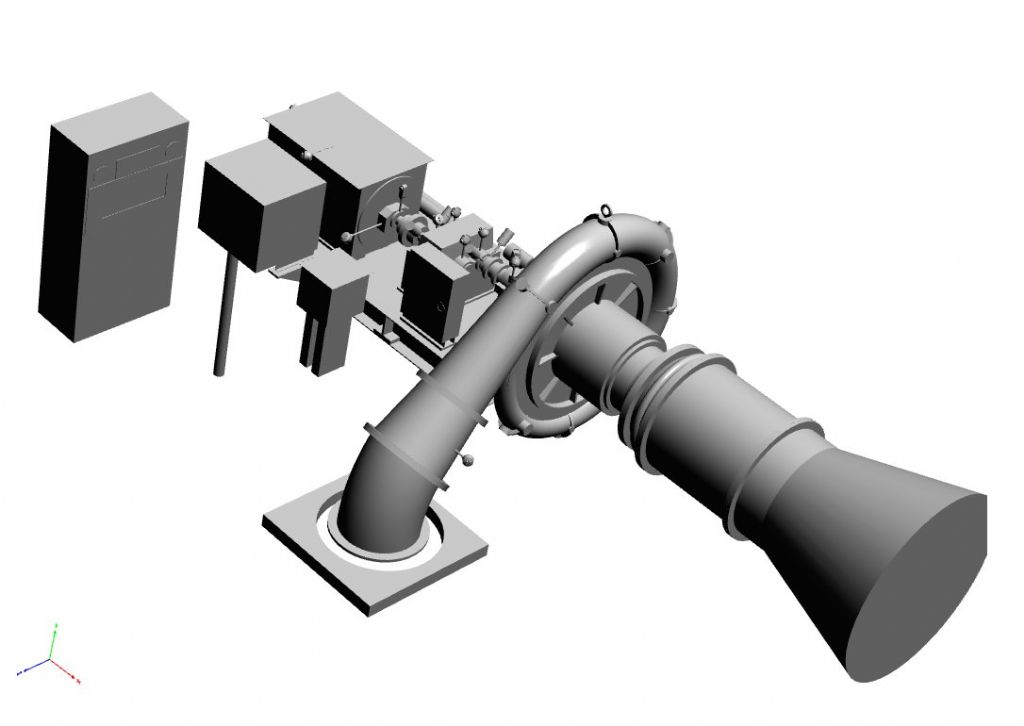

In my opinion, 3D modeling is having a more profound affect on the engineering world than say the wheel, or fire.

3D models are interactive, and thus any change in the base model propagates immediately and automatically to every 2D drawing, with no human intervention required.

I use 3D modeling for model engines (and work projects), and I can run an engine virtually, and test for interferences.

If my 3D model is not absolutely correct, the virtual model will not run, so I know when I try new engine designs that they will run flawlessly when constructed. There is all sorts of data that can be extracted from a virtual model, such as mass, balance, velocity, acceleration, etc., and so one can measure the vertical and horizontal forces being generated from a virtual engine that is being run, and find out how badly it will vibrate.

.

Edited By PatJ on 12/01/2022 03:24:54

Edited By PatJ on 12/01/2022 03:25:45

Edited By PatJ on 12/01/2022 03:26:32

Edited By PatJ on 12/01/2022 03:27:17

Edited By PatJ on 12/01/2022 03:28:42

Edited By PatJ on 12/01/2022 03:33:56

Edited By PatJ on 12/01/2022 03:34:56

Edited By PatJ on 12/01/2022 03:51:53

JA.

JA.