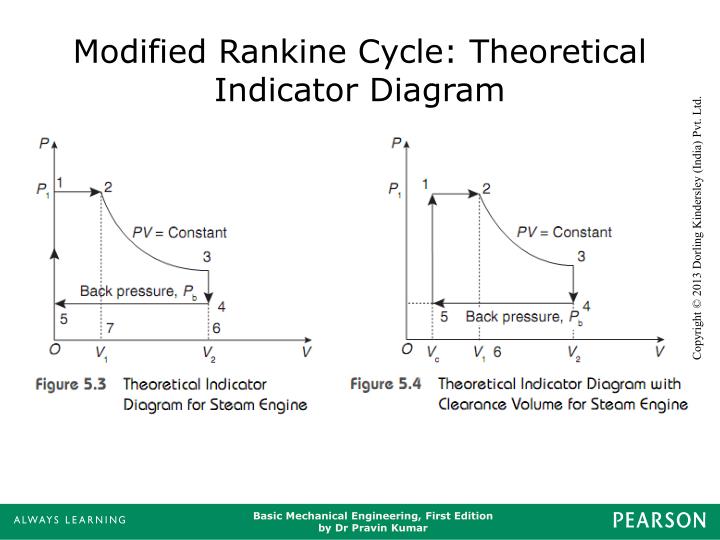

No, I would not dismiss the theoretical indicator-diagram outright. It will not match reality, but act as a guide to designing the engine and subsequent testing, and I think were used as such industrially.

'

Sometimes I wonder how those designers managed without computers and animated graphics of valve-gears!

Well, they did, using the Realeaux Diagram or similar to find the virtual-eccentric for the desired full-gear and mid-gear valve travels; and trigonometry and geometrical construction for the motion to give those characteristics.

Once the generic formulae and geometry had been established and published, it was probably a lot easier than it seems, and did not need the extra skill of programming a computer to do maths one already knows! The arithmetic by slide-rule and books of tables was slower than by our using a calculator; arguably manual drawing is slower overall than by CAD, but that is all.

I am not knocking using computer simulations as such for those with a parallel interest and high skill in computing, but regard them as an interesting adjunct. You still need to understand the machine, and though I do not see using a computer here as automatically an efficient design tool, I respect it as an academic exercise.

I do use CAD and occasional spread-sheets, partly because they readily allow determining the effect of changing a value. I have used them in my steam-wagon project, and most recently a spread-sheet for close-approximation metric screw-cutting on my EW lathe. Yet I am designing the wagon's engine from established examples, and need overhaul the lathe before worrying about gear charts.

'

Apart from a couple of inherited ones, my handful of old text-books came from a second-hand book-shop with a strong line in transport and other technical themes. They were not expensive, either. I looked for CAD primers too, but the shop had almost no books on computing. The proprietor explained that unlike science and engineering books, IT manuals are out of date so rapidly they are almost un-saleable!

'

Reg –

Interesting! Costly though; although to be fair that is a multi-purpose system. I was thinking only of indicator tests, not also dynamometer tests, and their system is very much intended for testing locomotives, not road or stationary steam engines. Maybe it's something a large club with its own railway, rather than individual, would buy.

My suggestion for a piezo-electric sensor came from one of my old books, plus testing small hydrophones at low frequencies co-incidentally appropriate to steam-engine speeds. Those versed in electronics and computers – and rich enough – could probably make such an indicator, and not withstanding my refusal to worship computers, link it to a storage oscilloscope or a PC-based instrument-simulator like Labview.

However; I am not sure how to calibrate the resulting system sufficiently for the project to be worthwhile, but it would entail constructing a calibration-rig rather like a small compressor driven at precisely known speeds. (The trade version is called a 'piston-phone', but for a different purpose so it uses sub-millimetric displacements and deeply sub-Pascal pressures. Not the typical miniature steam-engine's real dV and dP.)

'

Basically though, I think all this joule-chasing and computer-programming is interesting academically, but I'd rather make and operate a real reciprocating steam-engine by established principles that give me the chance of it working as well as I can make it, and for its own sake – not try to re-invent the invented!

duncan webster 1.