Engine rebuild

Engine rebuild

- This topic has 30 replies, 6 voices, and was last updated 2 February 2016 at 13:31 by

gavin compton.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Easiest/cheapest source of R8 socket

- Even the Dealer Didn’t Know!

- How many spokes do I really need?

- Model Engine running just off a naked flame

- Please direct me to where I can find an engineer to do some bespoke work

- What Did You Do Today 2025

- Herbert B drill information?

- Which lubricator do I need

- Backplate studs

- William Hazeldine … Proving Machine

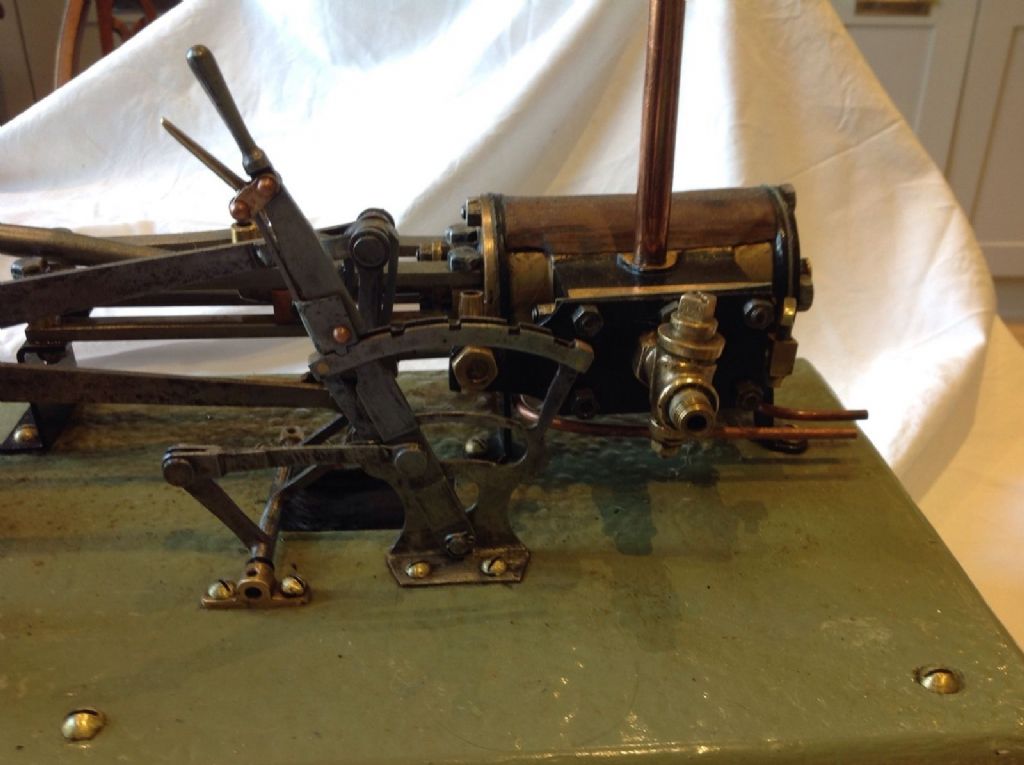

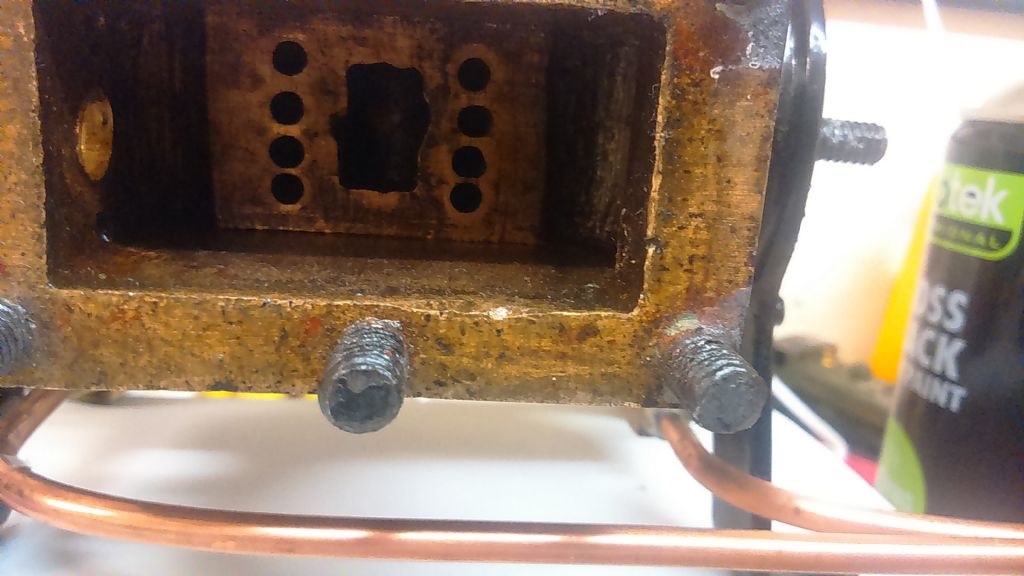

they are studs. you right about the "L" looking werid. guess im just being picky. i could thread a bit of round bar and then blend the round bar on to the other end of the eccentric rods,if the angle wrong i would sliver solder at correct angle. then again if it not broke………..

they are studs. you right about the "L" looking werid. guess im just being picky. i could thread a bit of round bar and then blend the round bar on to the other end of the eccentric rods,if the angle wrong i would sliver solder at correct angle. then again if it not broke………..

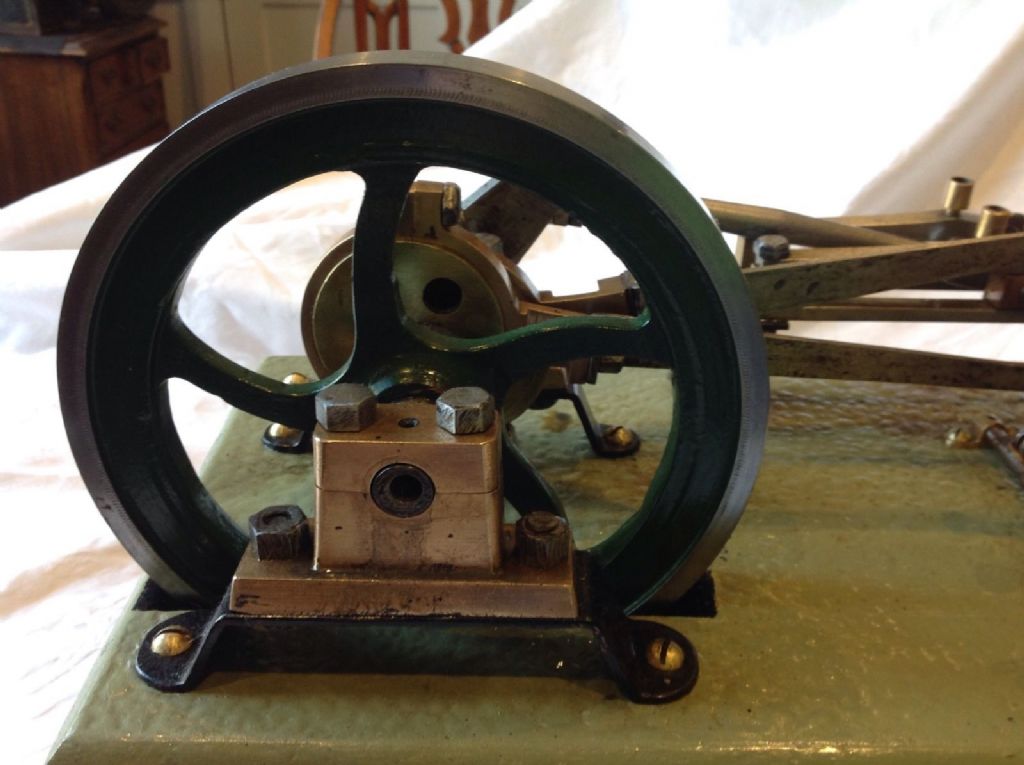

there a 10mm twist/lift on front left to rear right. there no screws just two studs clamping the two cross members in place. i had to cut the studs as the nuts and holes was filled with epoxy. inspecton of the cross members showed they are not cut sq. so i can either repair and true up the base or start again,im not sure yet i hate wood work lol.

there a 10mm twist/lift on front left to rear right. there no screws just two studs clamping the two cross members in place. i had to cut the studs as the nuts and holes was filled with epoxy. inspecton of the cross members showed they are not cut sq. so i can either repair and true up the base or start again,im not sure yet i hate wood work lol.