Neil (Stub) – I think the requirement for symmetric waveforms will depend on the subsequent electronics – IMO most 'dumb' electronic systems (TTL, CMOS, etc) would probably clock on the edges of the pulses, implying that so long as the waveforms were present with reasonably fast edges, then the symmetry is not so important for a simple system using only leading edge detection.

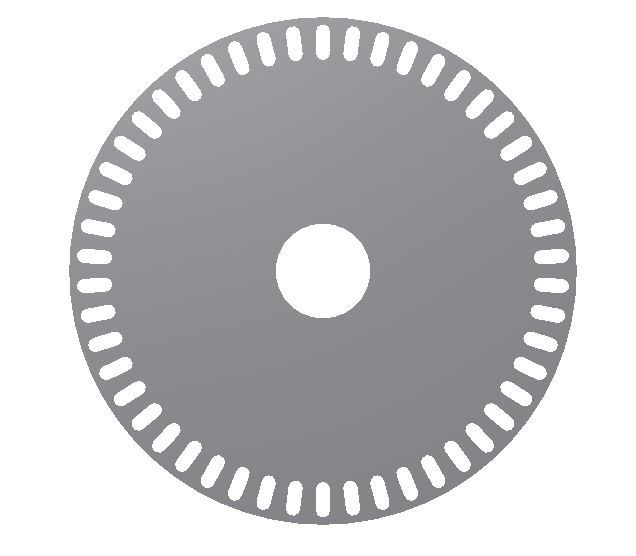

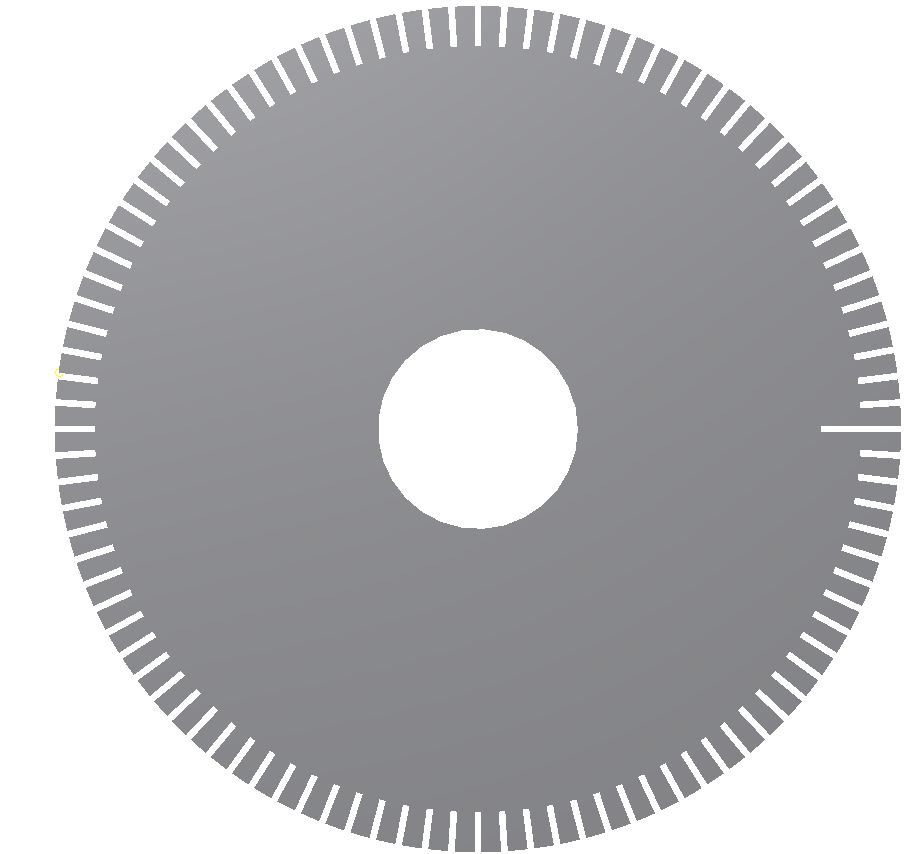

However, one way to increase the number of pulses per rev is to use both the rising and falling edges of the waveform, and in that case, the quadrature waveforms need to be symmetrical, otherwise the pulses will tend to occur in pairs (two pulses, followed b a longer gap, then two more pulses – hope that makes sense). It is easy electronically to detect the rising and falling edges and combine them to provide quadrature pulse trains, providing two pulses for each slot in the wheel.

This method was used in the original German design for an Electronic Lead Screw (sorry – forget the guys name just now) – there was some discussion about this in this forum. (Tony Jaffee is the expert on this, I think).

An alternative to using a mechanical gearing system to increase resolution would be to use electronic phase-locked loop pulse multiplying system – I assume you want to measure rotational speed rather than absolute shaft position – this (put simply), is just an oscillator which produces the required output pulse. This output is divided by whatever multiplication is desired (e.g. 5), so a train of pulses at 1/5 the output frequency is produced. These pulses are compared with pulses produced from the optical wheel system, and an error signal is generated by the difference between the two pulse rates. This error signal is used to make the oscillator 'track' the mechanically produced pulses, but at (in this example) 5 times the frequency. There are easily available devices to perform this function (E.g CMOS 4046 and variants), or nowadays, PIC microcontrollers and the like can be programmed to do it.

Another possible method is to measure the time between pulses, rather than the number of pulses per revolution. For example, if you have the simplest system with 1 pulse per revolution, then one (shaft) pulse can be used to trigger a counter driven by a high speed pulse generator. The following pulse from the shaft pulse generator indicates the end of the count. The number of pulse generator pulses counted between shaft pulses is a direct indication of shaft rotational speed, and can be many thousands if required. Note that any system using this will have some lag in response times (depends largely on how it is designed), because (in my example) at least one revolution must take place before a count is available. I don't think this is an issue for the requirement of hobbing, if you just want to maintain a definite ratio between the rotation of two components.

Hope some of this is useful.

Sub Mandrel.